Apparatus and method for preparing pressure nitrogen gas with air separation

An air separation and pressure technology, which is applied in the direction of nitrogen purification/separation, can solve the problems of increasing the energy consumption of nitrogen production and failing to further reduce it, and achieve the effect of increasing the extraction rate, reducing energy consumption, and reducing the height of the cold box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

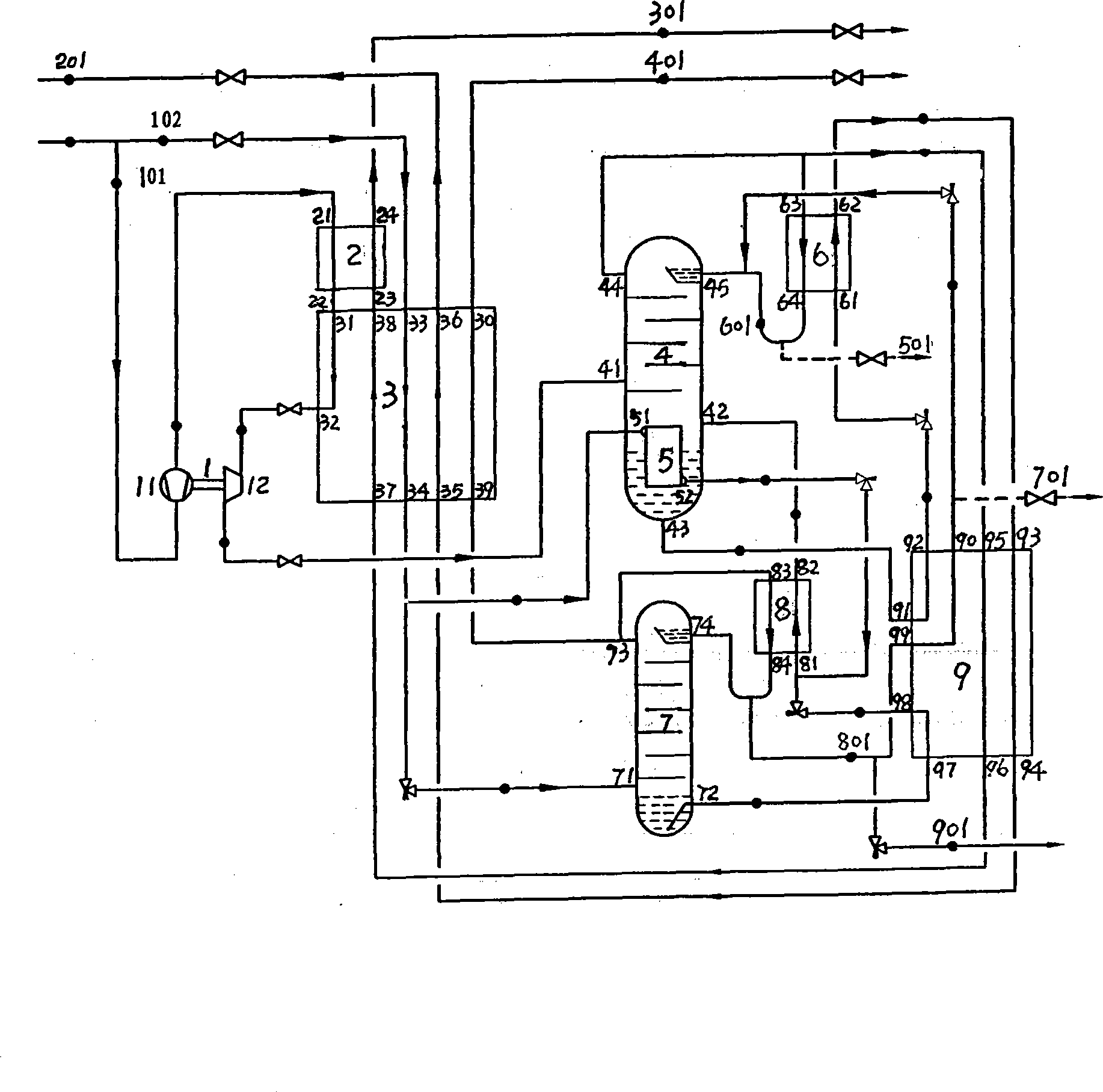

[0027] see figure 1 , the device for producing pressure nitrogen by air separation of the present invention comprises a booster turbo expander 1, an air cooler 2, a main heat exchanger 3, a low-pressure tower 4, a reboiler 5 arranged in the low-pressure tower, a low-pressure tower Condensing evaporator 6, high pressure column 7, high pressure column condensing evaporator 8 and subcooler 9. Wherein the low-pressure column 4 and the high-pressure column 7 are arranged side by side in the same cold box.

[0028] The inlet of the pressurized end 11 of the supercharged turboexpander 1 is connected to the raw air pipeline 101, the outlet is connected to the raw air inlet 21 of the air cooler 2, and the raw air outlet 22 of the air cooler is connected to the first raw material of the main heat exchanger 3 The air inlet 31 and the first raw air outlet 32 of the main heat exchanger are connected to the inlet of the expansion end 12 of the supercharged turboexpander, and the outlet o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap