Car body dynamic intensity analysis method

A technology of dynamic strength and analysis method, applied in the field of analysis, can solve the problems of complex cost of six-component force and inability to convert results, and achieve the effect of shortening the test period and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following content is a further detailed description of the present invention in conjunction with specific preferred embodiments, and it cannot be assumed that the specific implementation of the present invention is limited to these descriptions. For those of ordinary skill in the technical field of the present invention, without departing from the concept of the present invention, some simple deduction or replacement can be made, which should be regarded as belonging to the protection scope of the present invention.

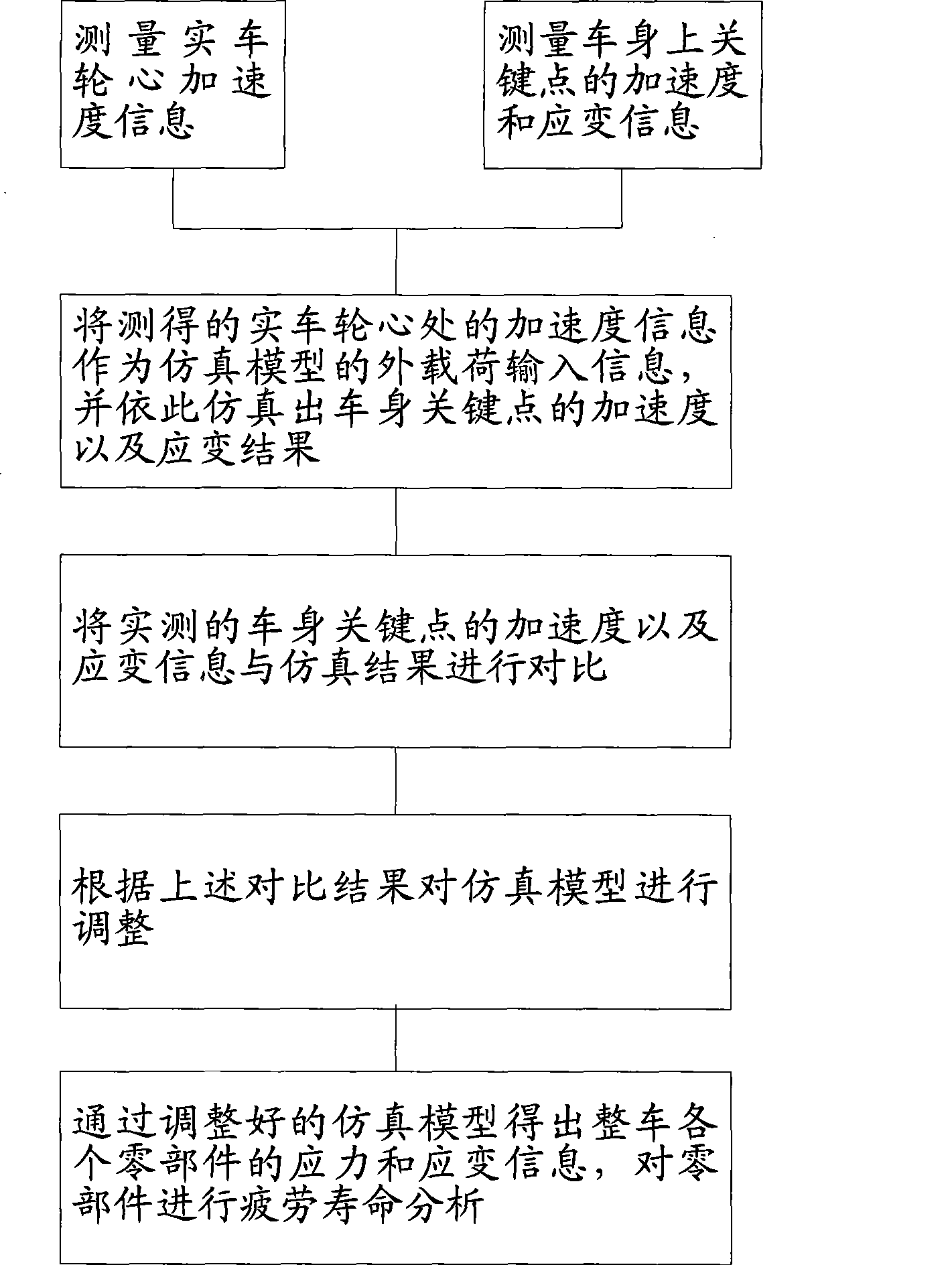

[0012] see figure 1 , a vehicle body dynamic strength analysis method includes the following steps:

[0013] a. Simultaneously measure the acceleration information of the real wheel center and the acceleration and strain information of key points on the vehicle body;

[0014] b. Use the measured acceleration information at the center of the real wheel as the external load input information of the simulation model, and simulate the acceleration and str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com