Plastic bottle cap bactericidal device and bactericidal method thereof

A technology of sterilization device and bottle cap, applied in the direction of chemistry, etc., can solve the problems of inability to achieve the sterilization effect of drug filling, the inability to achieve the sterilization effect, and the large space occupied by the equipment, so as to reduce the consumption of raw materials, improve the sterilization effect, and achieve a compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

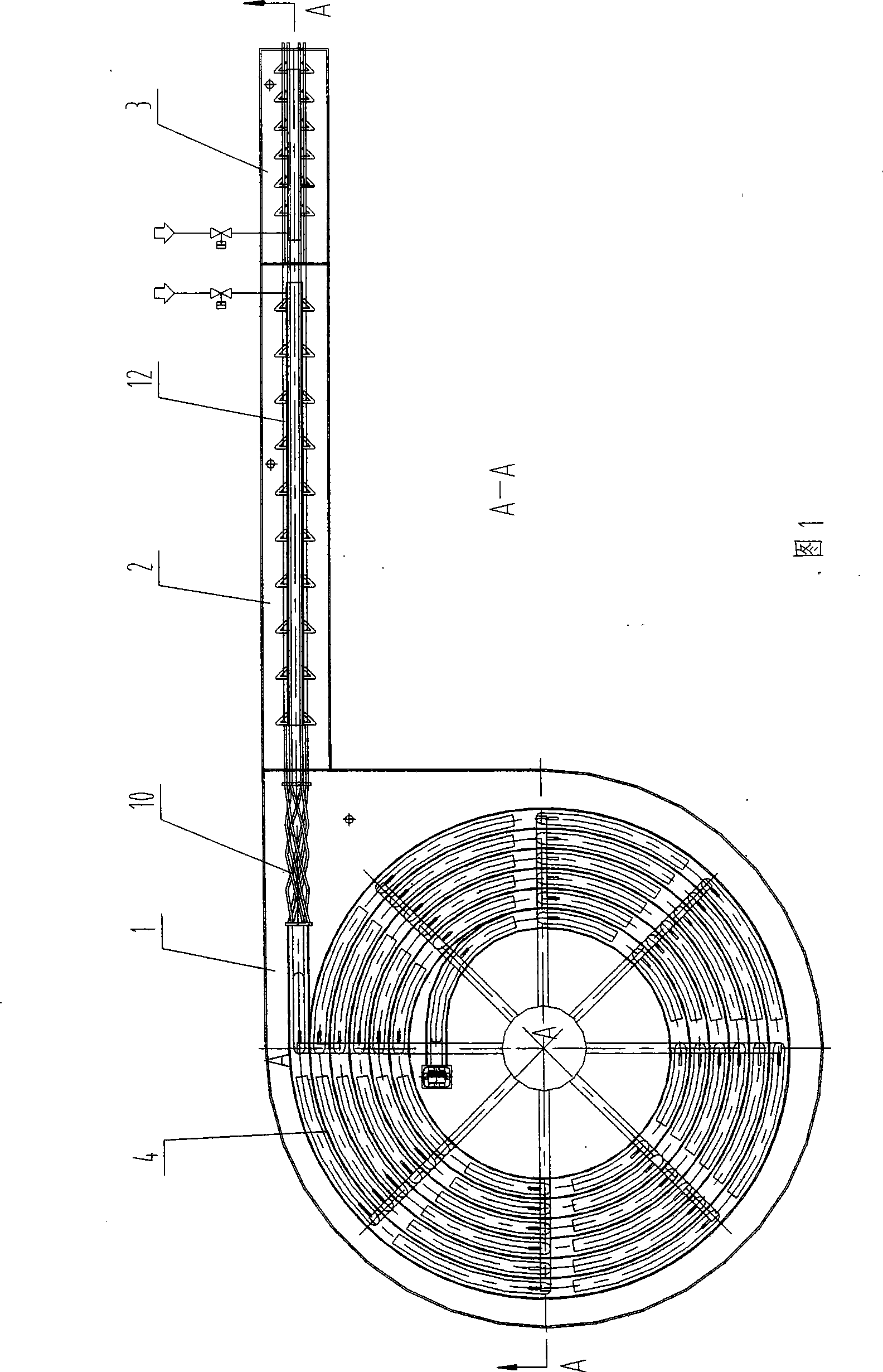

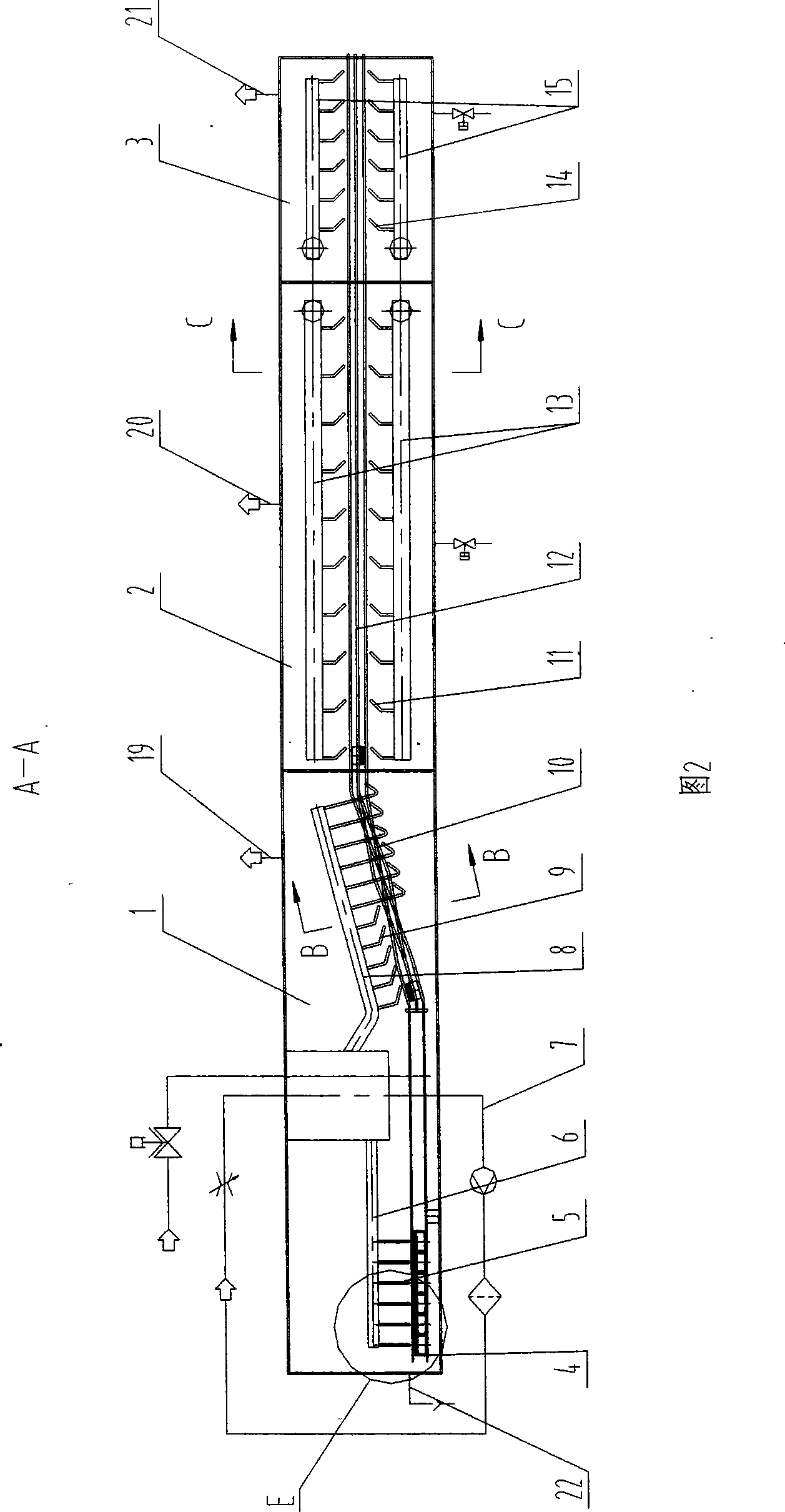

[0021] In Fig. 1 and Fig. 2, the plastic bottle cap sterilizing device of the present invention comprises: soaking sterilizing chamber 1, aseptic water spraying chamber 2, aseptic air spraying chamber 3.

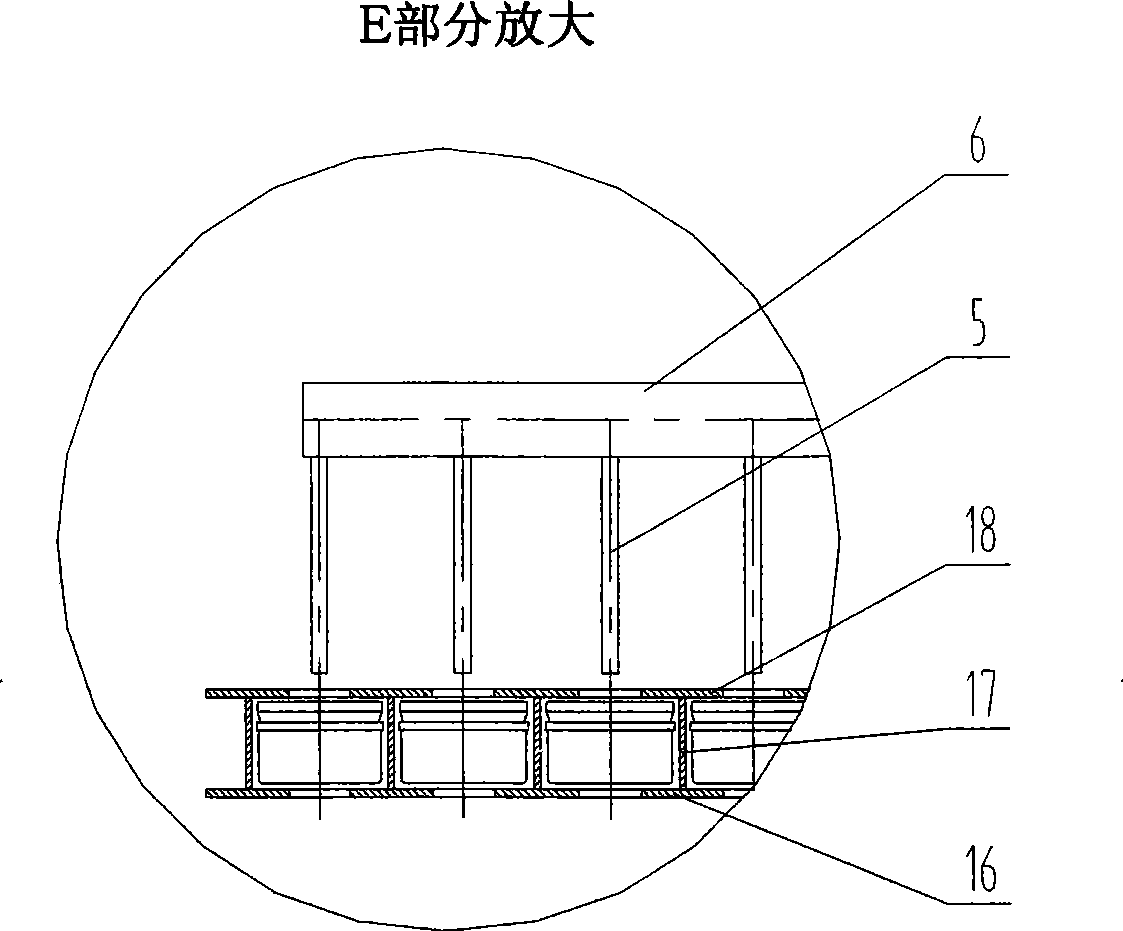

[0022] In the immersion sterilization chamber 1, the helical curve of the spiral bottle cap channel 4 is an Archimedes spiral, and the unfolded length of the Archimedes spiral satisfies: Under the given production capacity, the travel time of the bottle cap in the spiral channel satisfies The time (such as 30 seconds) required for the bottle cap to be completely sterilized. The screw cap channel 4 consists of ( image 3 Middle) the upper fixed plate 18 that has spiral groove, the lower fixed plate 16 that has spiral groove, spiral partition 17 is formed. Above the screw-type bottle cap channel 4, 8 concentric radiation-type sterilizing liquid (such as peracetic acid) pipelines 6 are set, and each pipeline is provided with the number of nozzles 5 equal to the number of paths ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com