Sand core coupling

A coupling and sand core technology, which is applied to cores, casting equipment, casting molds, etc., can solve problems such as affecting the quality of castings and cannot be effectively connected, and achieve good practical value, practical operation, and prevention. Drift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

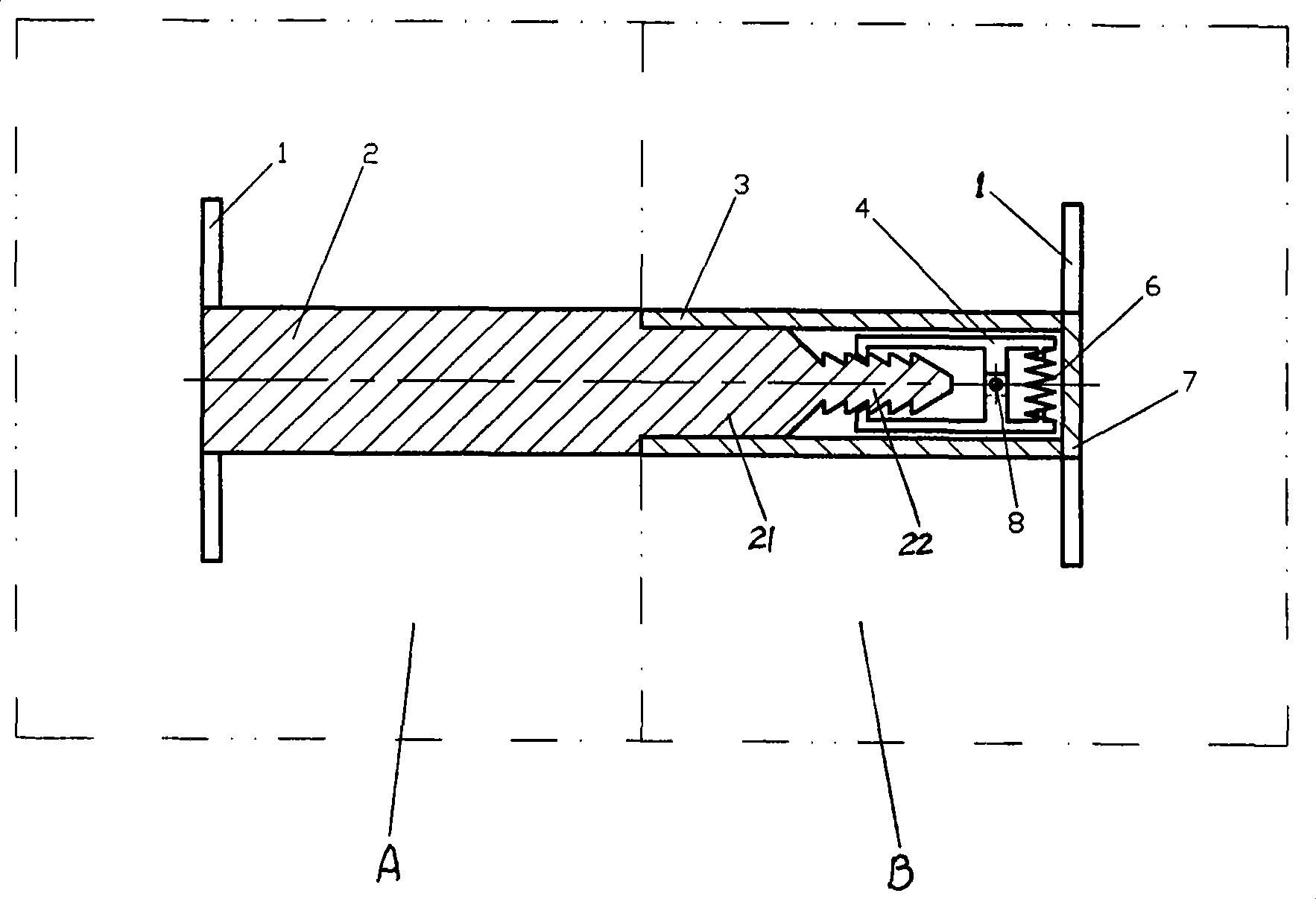

[0016] Referring to the accompanying drawings, the present invention is a sand core coupler, which is used for the connection between sand cores and sand cores or between sand cores and sand molds in sand casting production. The mark A in the figure is a sand core, and B is a sand core or a sand mold.

[0017] This sand core coupler is made up of spare parts such as coupler 2, coupler sleeve 3, hook 4, preventer 1, stage clip 6. The two break-off devices 1 are respectively arranged at the ends of the coupling piece 2 and the coupling sleeve 3. The break-off devices 1 are round or cross-shaped to strengthen the connection with the core (type) sand and prevent the coupler from falling from the core (type) out of the sand.

[0018] The coupling piece 2 is set into the coupling sleeve 3 and connected with the coupling sleeve 3 and the hook 4 . The front part of the coupling part 2 is provided with a guide part 21 and a coupling part 22 , the coupling part 22 serves as the head o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com