Pneumatic two-position two-way piston type multi-medium angle seat valve with buffer

A two-position two-way, piston-type technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of not meeting the high-pressure work requirements, limited performance, vibration and noise, etc., and achieve easy integration of automatic control, Good use performance, the effect of improving the use performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

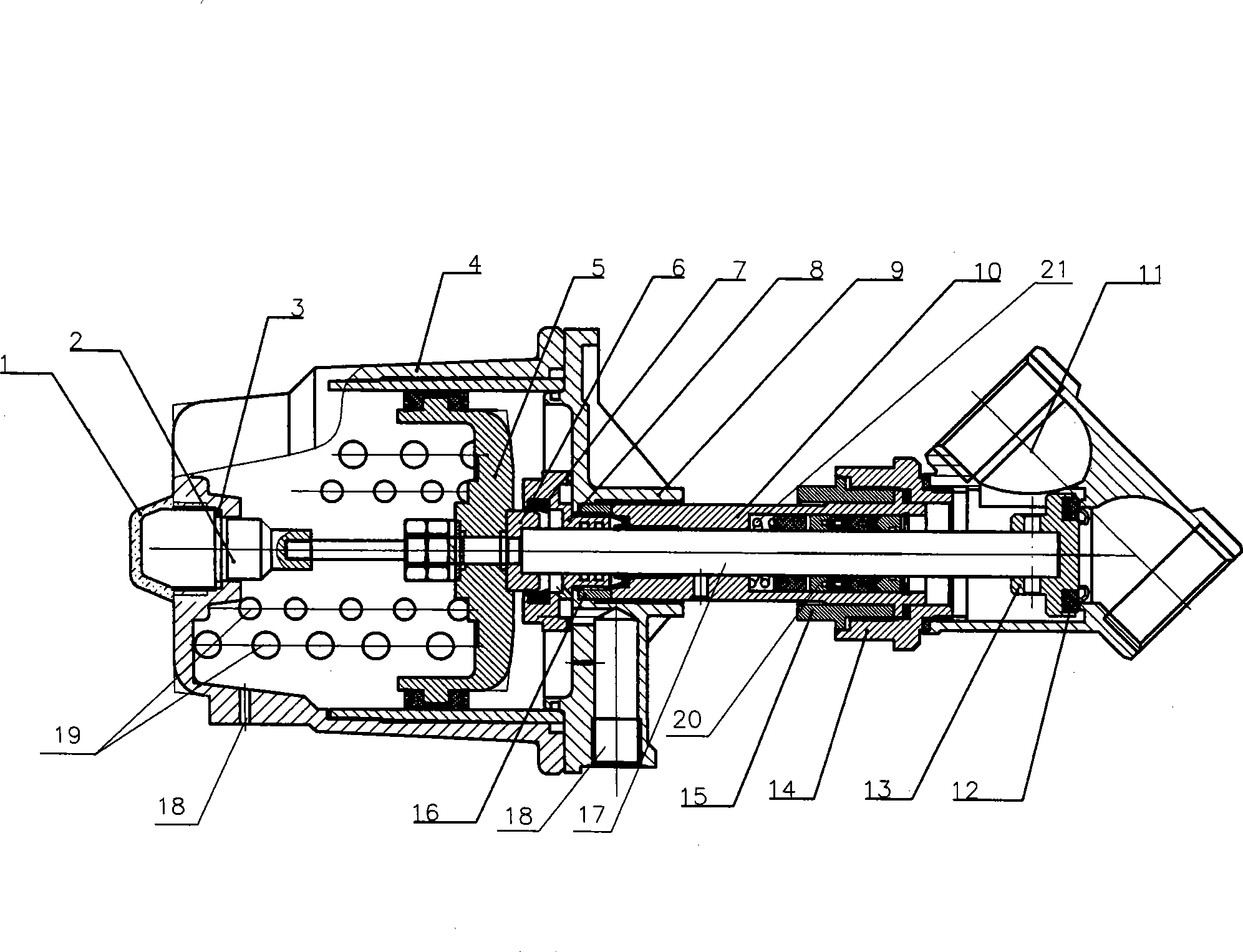

[0018] Such as figure 1 As shown, it is a schematic structural diagram of a pneumatic two-position two-way piston type multi-media angle seat valve with cushioning, which consists of an observation window 1, a sign rod 2, an O-ring 3, an aluminum cover cylinder 4, a piston 5, a cushioning piston 6, Buffer ring 7, buffer assembly 8, bottom cover 9, socket 10, two-position two-way piston type multi-media angle seat valve body 11, valve gasket 12, valve 13, nut 14, joint nut 15 socket nut 16, piston Rod 17, gas inlet and outlet 18, first spring 19, seal 20 and second spring 21.

[0019] The two-position two-way piston type multi-media angle seat valve body 11 is fixed and sealed with the socket 10 through the nut 14 and the joint nut 15, and the socket 10 is fixed and sealed with the bottom cover 9 provided at the front end of the cylinder body 4 through the socket nut 16 , the piston rod 17 is located in the middle of the cylinder body 4 and the sleeve 10, one end of which is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com