Lens barrel

A lens barrel and fixed mirror technology, applied in the field of lens barrels, can solve problems such as lens scrapping, rework, and assembly errors, and achieve the effects of reducing production man-hours, reducing production costs, and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

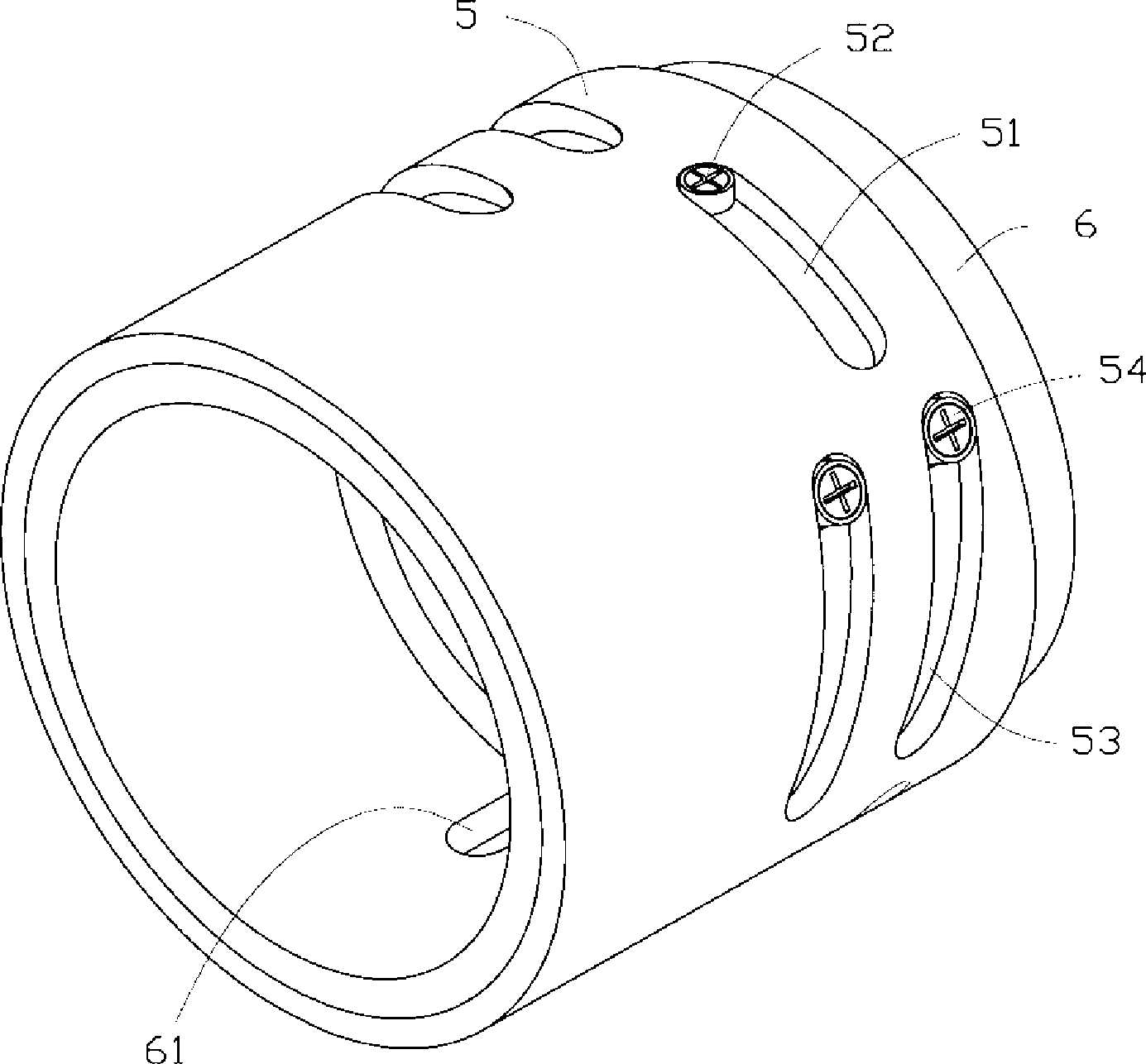

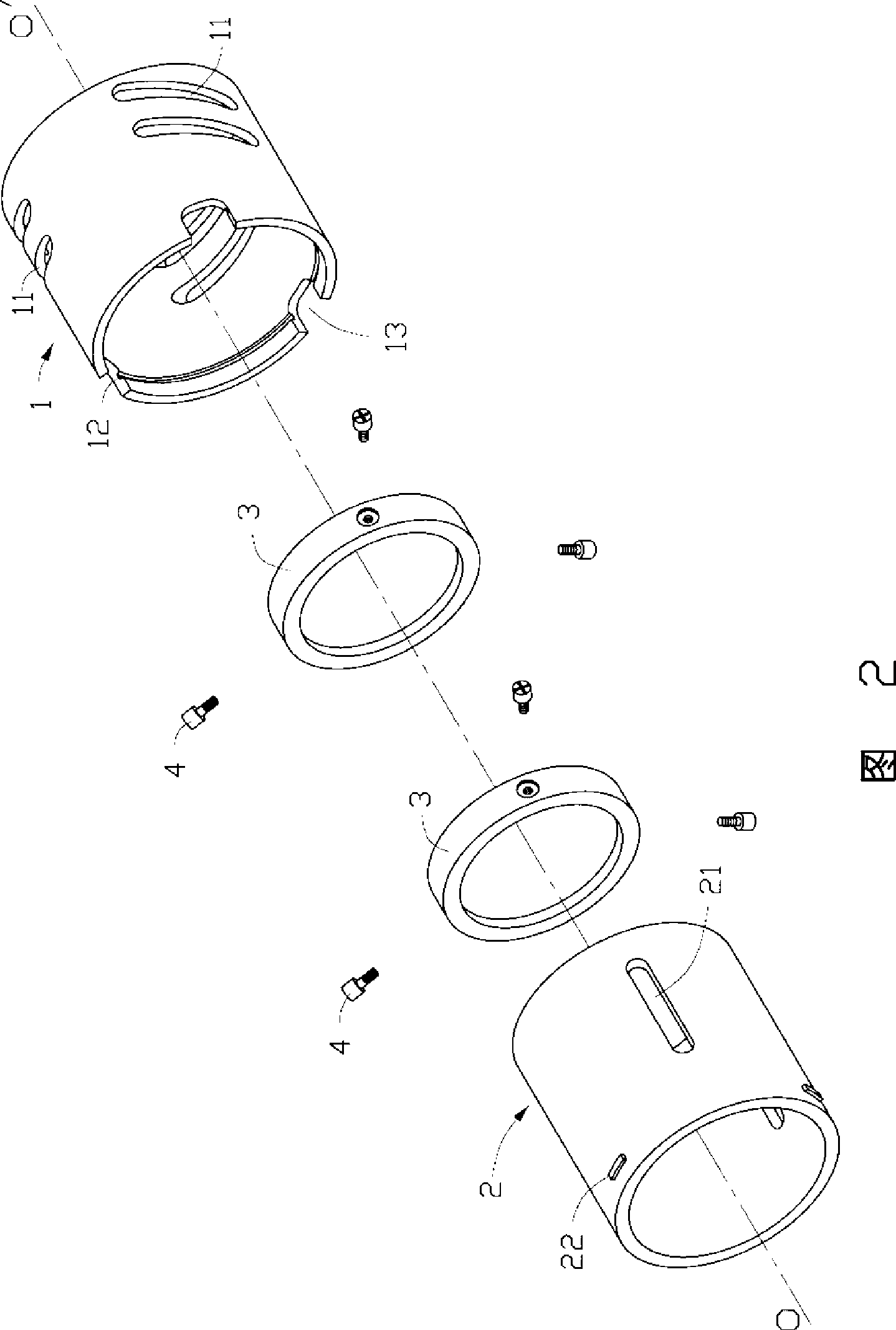

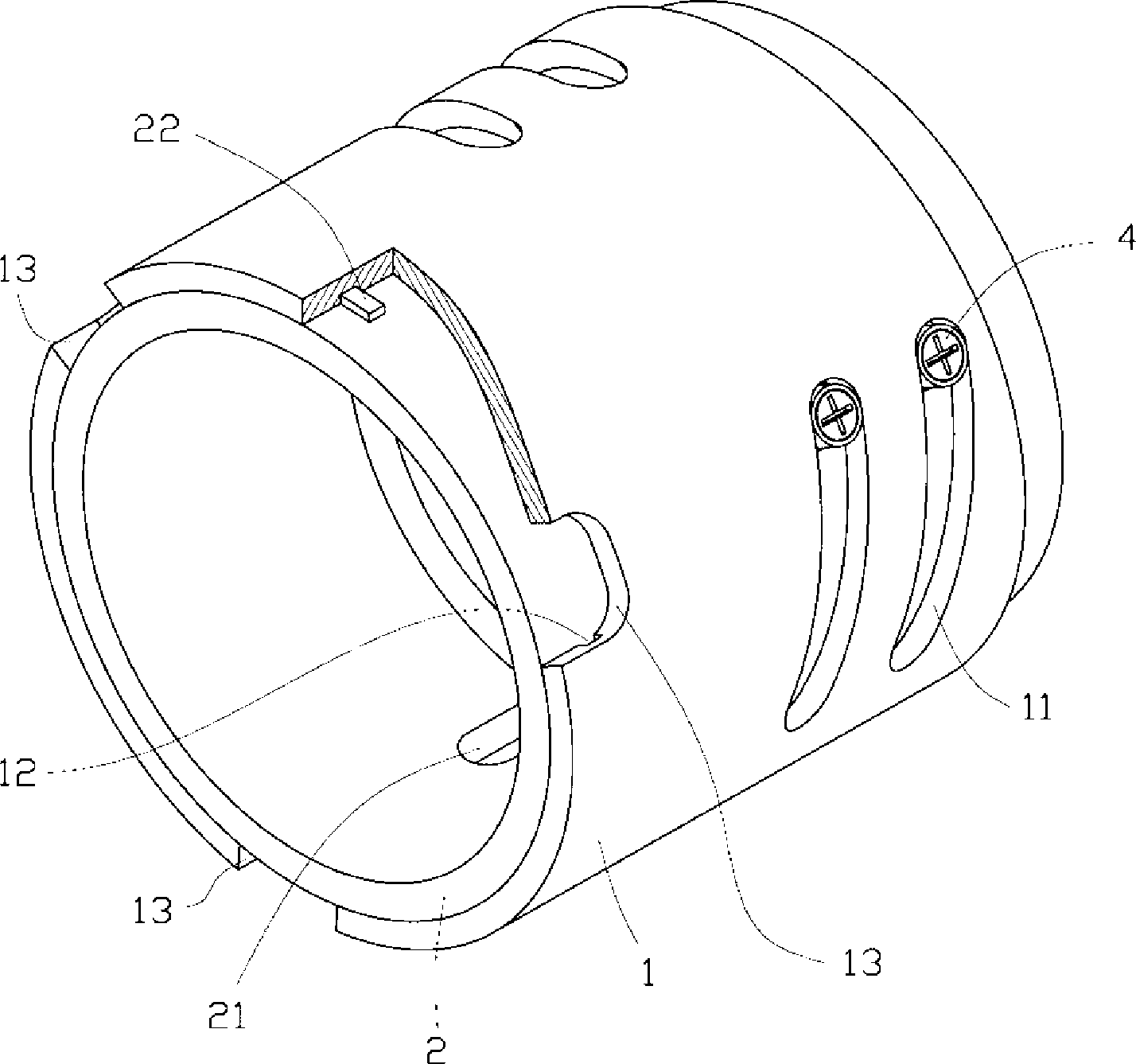

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] Please refer to FIG. 2 , which is an exploded view of the lens barrel according to the embodiment of the present invention. The lens barrel can be used in conventional cameras, digital cameras, video cameras, and projectors, and in this embodiment, the lens barrel is used in projectors.

[0014] The lens barrel includes a rotating lens barrel 1 , a fixed lens barrel 2 , a lens group 3 and a guide 4 . The rotating lens barrel 1 and the fixed lens barrel 2 are hollow cylindrical. The fixed lens barrel 2 is fixed on the projector (not shown in the figure), and the rotating lens barrel 1 is sleeved outside the fixed lens barrel 2 and can rotate relative to the fixed lens barrel 2 . The lens group 3 is accommodated in the fixed lens barrel 2 . The guide 4 passes through the fixed lens barrel 2 and the rotating lens barrel 1 and is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com