Electronically commutated direct current machine sensor-less operation

A DC motor and electronic commutation technology, which is applied in the direction of electronic commutator, electronic commutation motor control, electrical components, etc., can solve the problems of inapplicability and cannot be used to determine the rotor position, and achieve the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

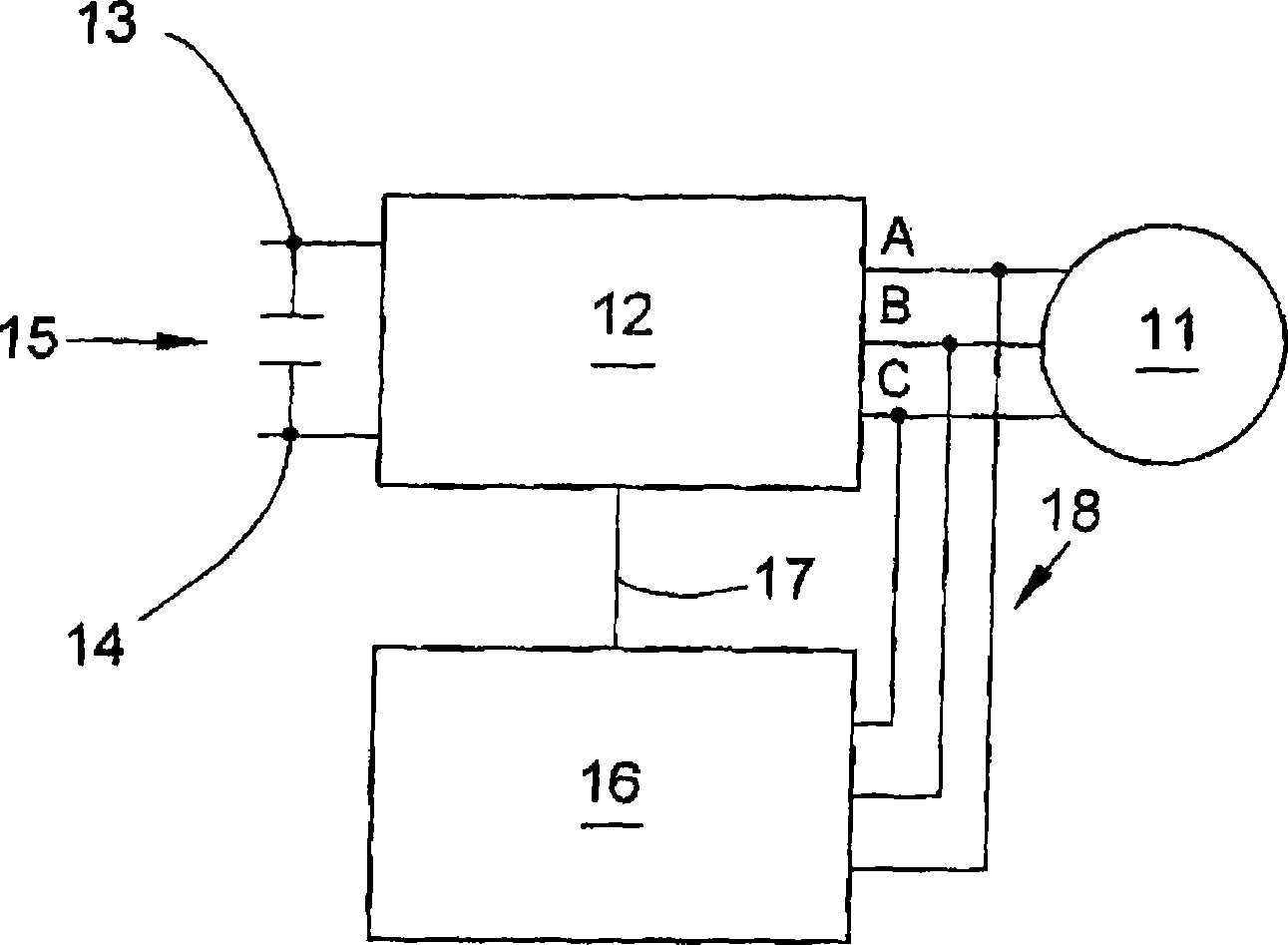

[0040] figure 1 A schematic diagram of an electronic drive according to the invention with an electronically commutated DC motor 11 is shown. The motor 11 consists of three-phase current windings in the stator and a permanent magnet excitation rotor. The terminals of the three phases A, B and C are connected to the inverter 12 . The inverter is connected to a DC voltage source. DC voltage source at figure 1 is represented by capacitor 15 and is connected to terminals 13 and 14 of the inverter. The inverter is controlled by a control unit 16 , and the inverter and the control unit are connected to each other by a control line 17 . The measurement line 18 connects the control device 16 to the three phases A, B and C to measure the induced voltage.

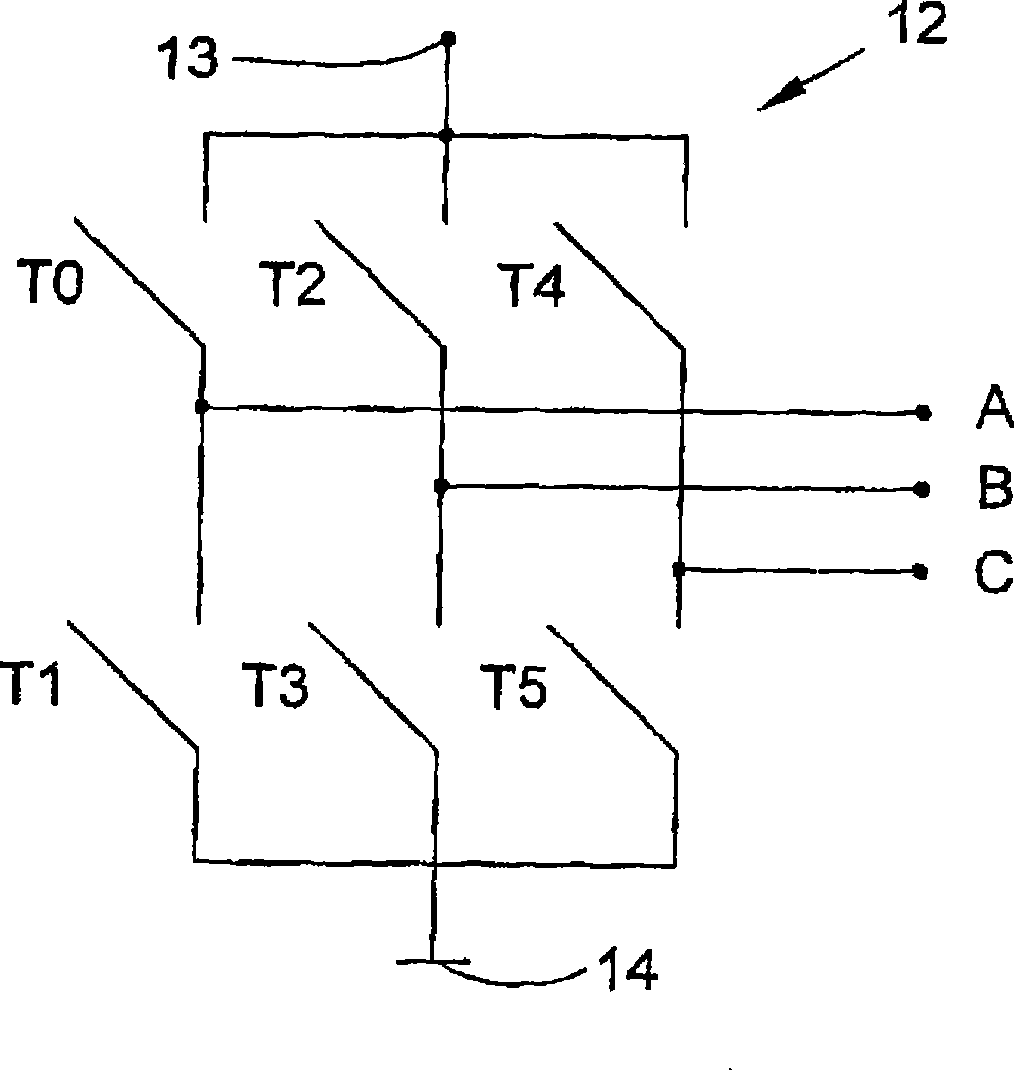

[0041] figure 2 The basic structure of an inverter 12 with DC voltage connections 13 and 14 and phase connections A, B and C is shown. The inverter is a three-phase bridge circuit with switches T0 to T5. The switch is config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com