Improved vibrating system for flat-plate loudspeaker

A flat-panel speaker and vibration system technology, applied to sensors, electrical components, etc., can solve the problems of difficult operability in the process, affecting the consistency of high-end frequency response, etc., to improve heat dissipation, improve high-end frequency response, and improve power tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

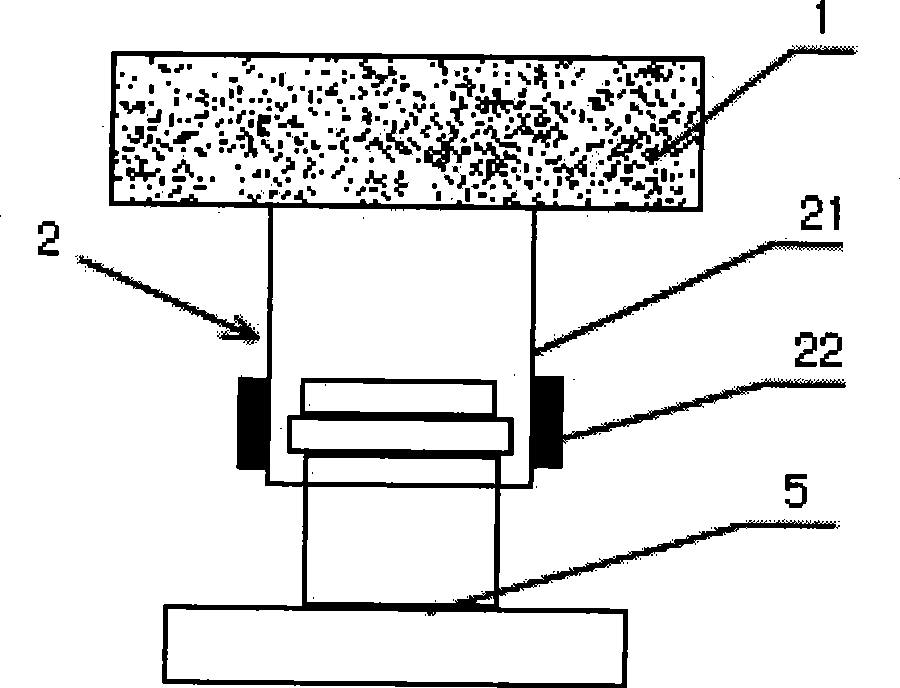

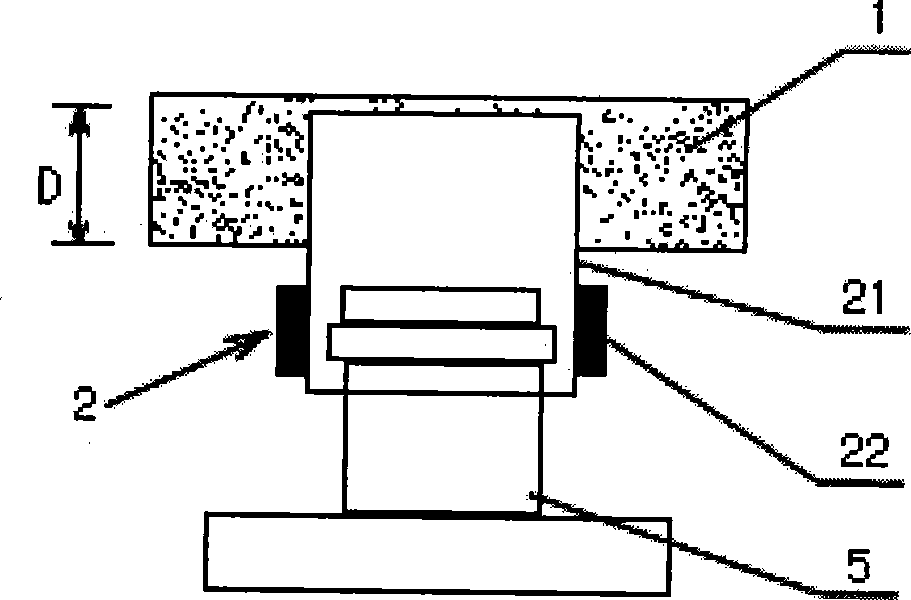

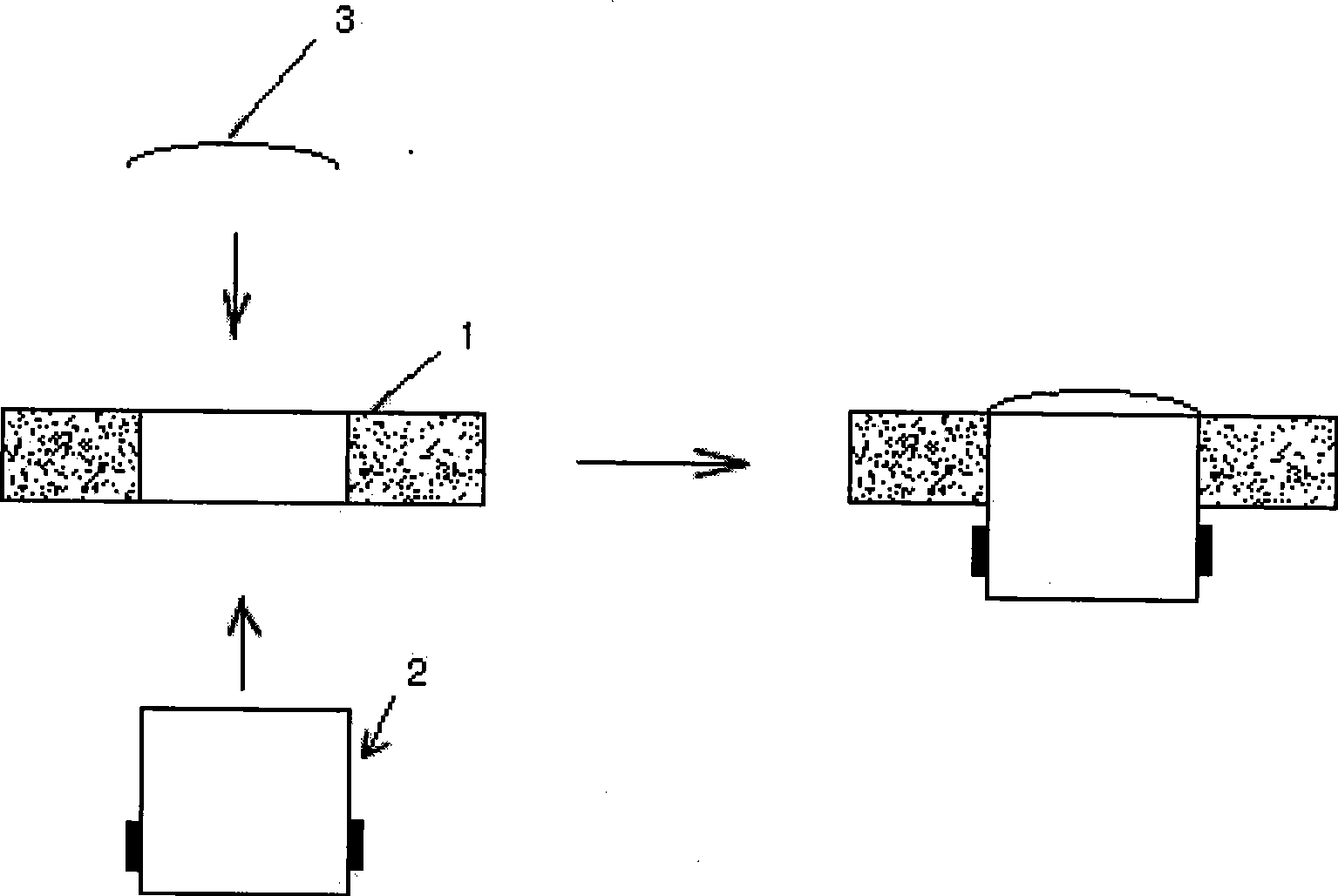

[0020] The structural details of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0021] This embodiment is an improved single-drive flat-panel loudspeaker vibration system, and its structure is as follows: Figure 5 As shown, the vibrating plate 1 adopts a lightweight foam board of φ5cm×thickness 0.5cm, and an improved voice coil 4 of φ2.8cm is installed on it. The voice coil 4 is an aluminum cylinder with a top, and its top surface is directly A sound film (that is, an aluminum sound film) is formed, and a coil is wound on the lower part to form an integrated sound film and voice coil. The voice coil 4 is installed and fixed on the side wall of the circular through hole in the middle of the vibration plate 1, and the top of the aluminum cylinder is in contact with the top of the vibration plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com