Method for correcting error of middle blank for pass-reversible rolling

A technology of deviation correction and rolling mill, applied in the direction of rolling force/roll gap control, contour control, etc., can solve the problems of difficult maintenance, false detection, high installation accuracy, etc., and achieve the effect of easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

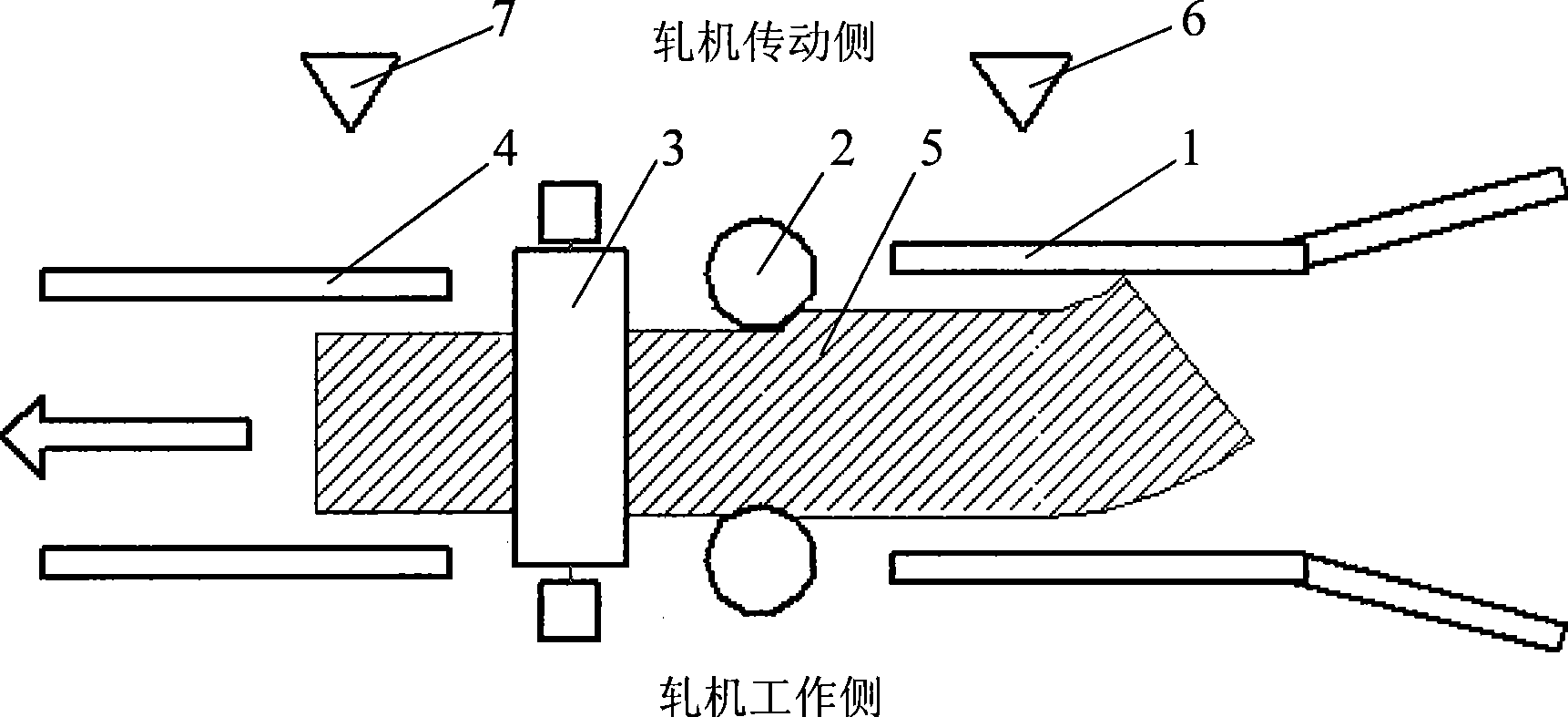

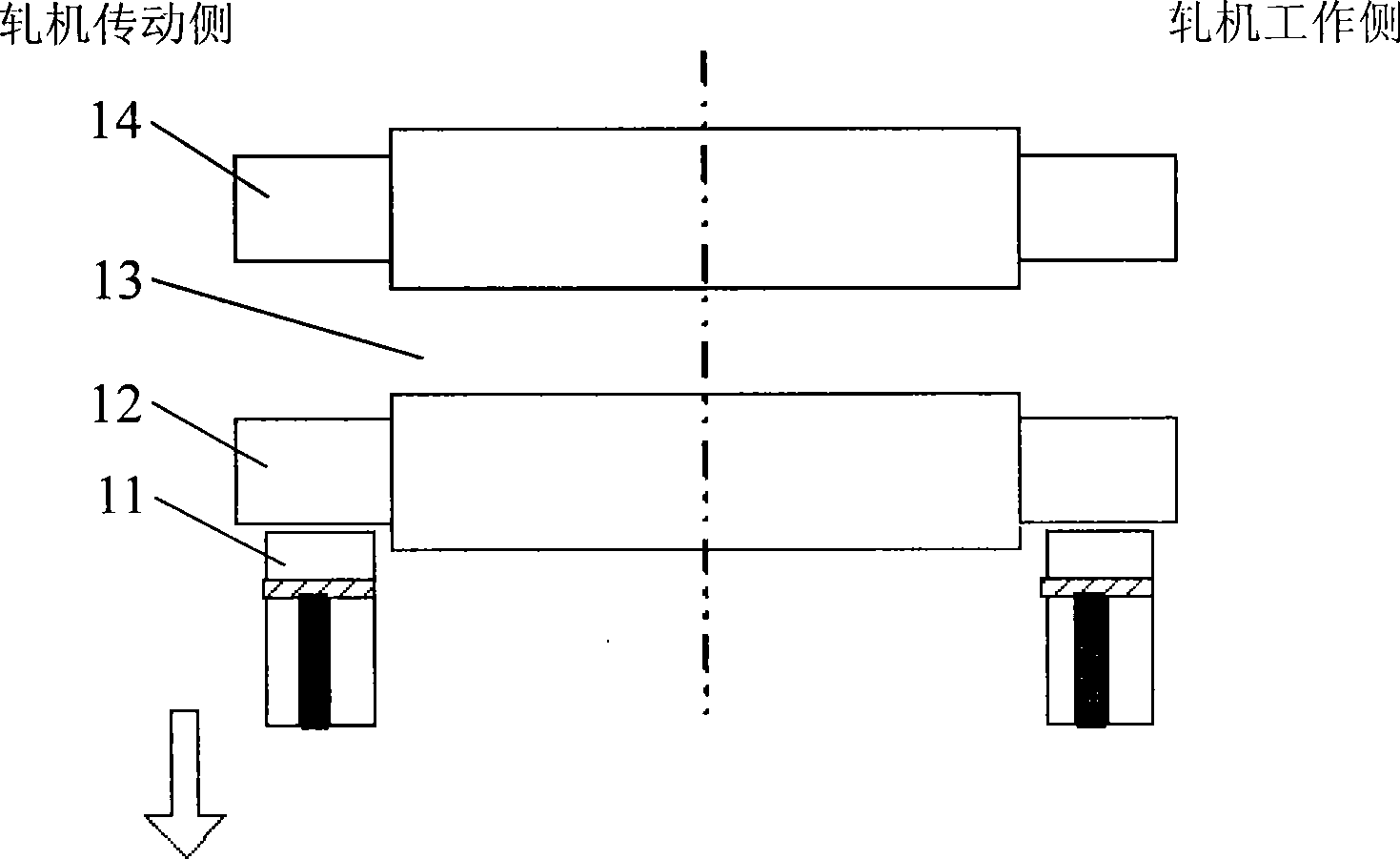

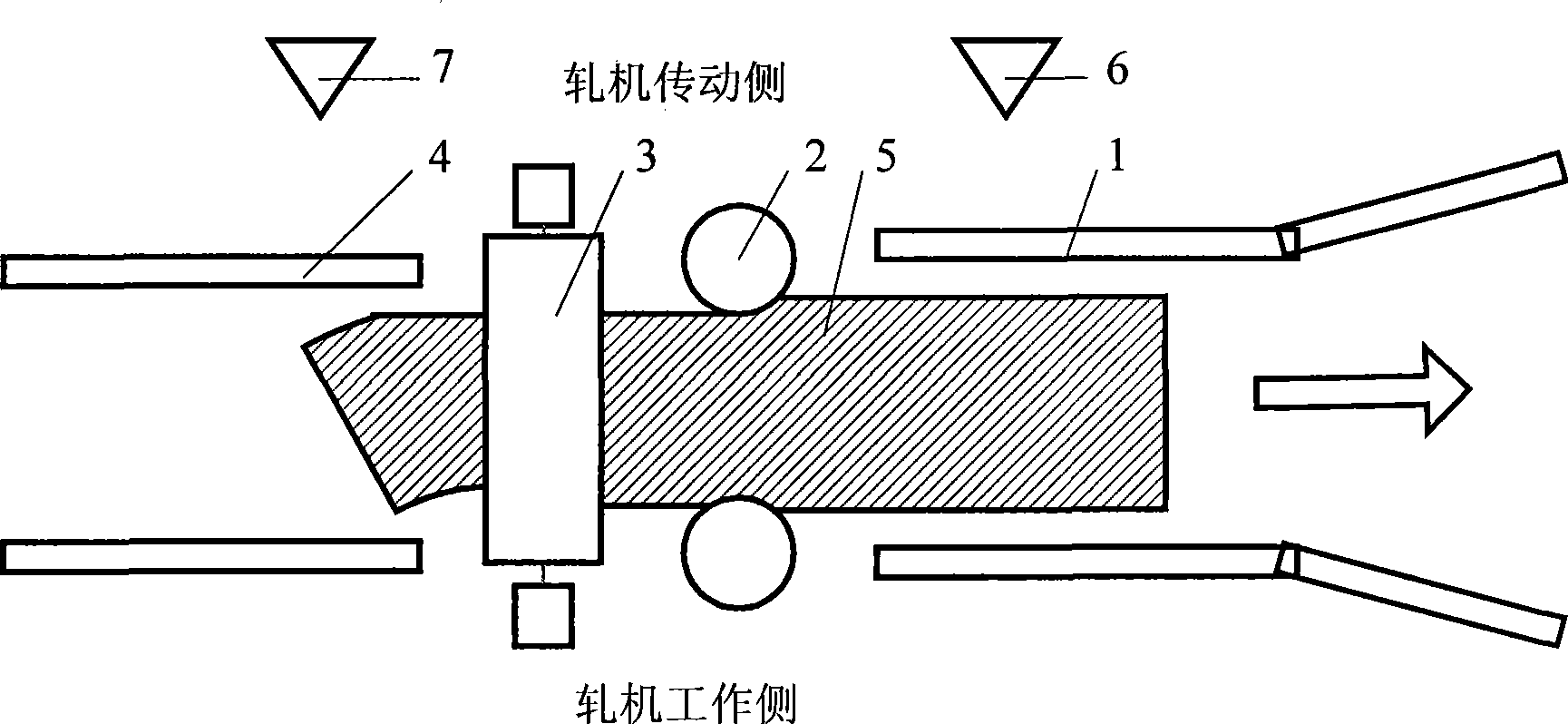

Method used

Image

Examples

Embodiment

[0045] The intermediate billet deviation correction method of the present invention has been used on the R2 rolling mill (horizontal rolling mill) of the three-hot rolling of a certain enterprise, and the following is the data obtained in the use process and the data are processed.

[0046] 1) The corresponding relationship between the detection pressure of the guide plate and the deviation amount of the intermediate billet

[0047] see Figure 7 , Figure 7 It is the correlation diagram between the guide plate detection pressure and the deviation amount of the intermediate billet. Since the maximum value of the guide plate detection pressure is 6mp, when the deviation is greater than 25mm, the guide plate detection pressure can only display 6mp.

[0048] 2) The relationship between the deviation of the intermediate billet and the adjustment of the roll gap

[0049] see Figure 8 , Figure 8 It is the relationship diagram between the deviation amount of the intermediate bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com