Method for producing multipurpose scraper

A multi-purpose, scraper technology, applied in applications, household components, household appliances, etc., can solve problems such as stiff feeling, reduced service life, uneven force control, etc., to overcome inconvenience in use, smooth working surface, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

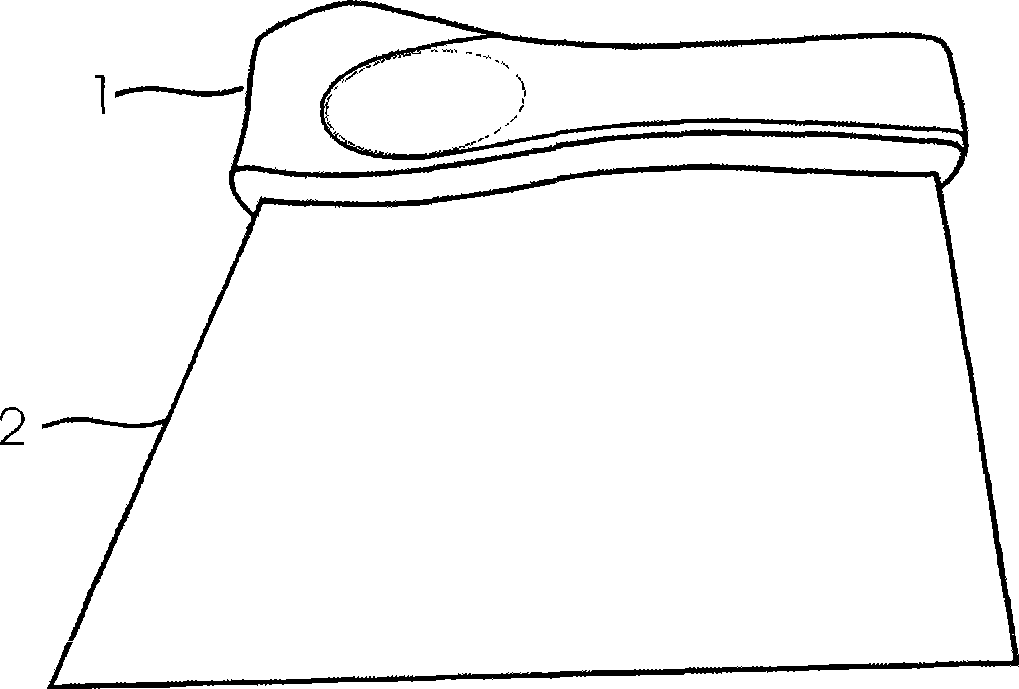

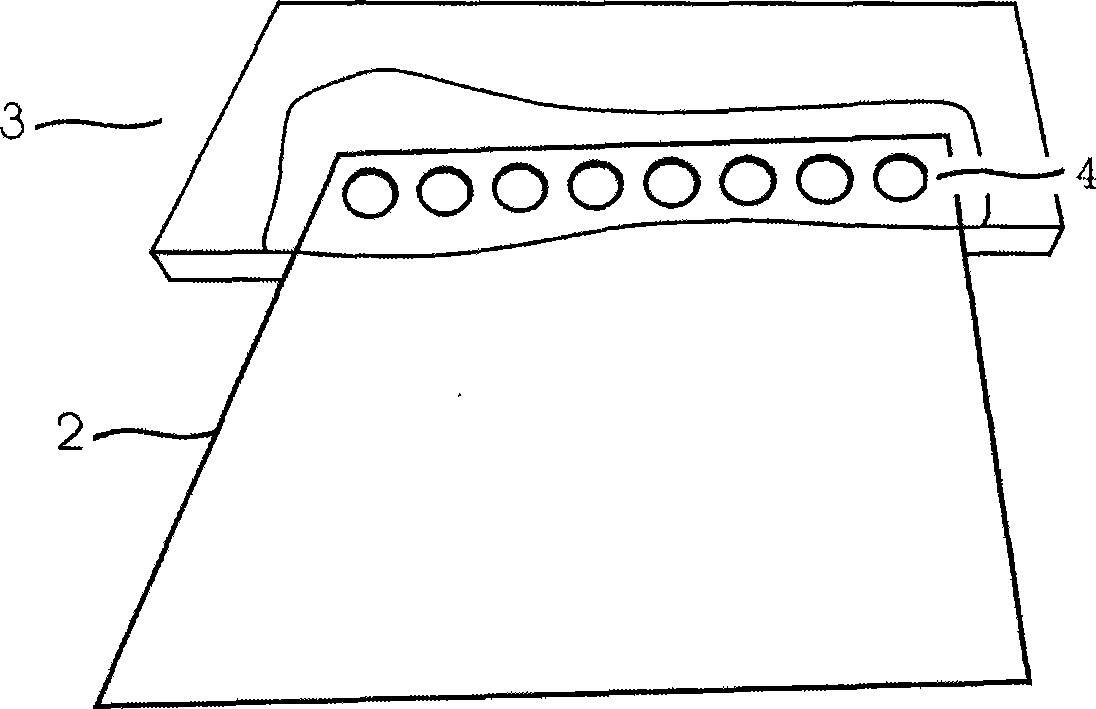

[0022] attached figure 1 It is a structural diagram of the product produced by the present invention, and its production method is as follows: firstly make a scraper blade stamping die, then stamp an epoxy resin laminate on the punch press to form a scraper blade 2, put the scraper blade punched on the punch press into the designed The appropriate position of the mold 3 is held by the handle, and the polyurethane liquid raw material is poured once, and molded for 15 minutes in an oven at 60° C. and in a sealed mold with a molding pressure of 50 kg.

Embodiment 2

[0024] attached figure 1 It is a structural diagram of the product produced by the present invention, and its production method is as follows: firstly make a scraper blade stamping die, then stamp an epoxy resin laminate on the punch press to form a scraper blade 2, put the scraper blade punched on the punch press into the designed Handle the appropriate position of the mold 3, add EVA resin and cast it once, and mold it in an oven at 90°C and in a sealed mold with a pressure of 100 kg for 12 minutes.

Embodiment 3

[0026] attached figure 1 It is a structural diagram of the product produced by the present invention, and its production method is as follows: firstly make a scraper blade stamping die, then stamp an epoxy resin laminate on the punch press to form a scraper blade 2, put the scraper blade punched on the punch press into the designed Handle mold 3 in the appropriate position, add polyurethane liquid raw material and cast once, mold 9 minutes in the oven of 120 ℃ and be molded in the airtight mold of 175 kilograms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com