Method for measuring brinell hardness

A measurement method, Brinell hardness technology, applied in the direction of testing the hardness of materials, etc., can solve the problems of affecting efficiency, low efficiency, and inapplicability, and achieve the effects of reducing labor intensity, accurate measurement, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

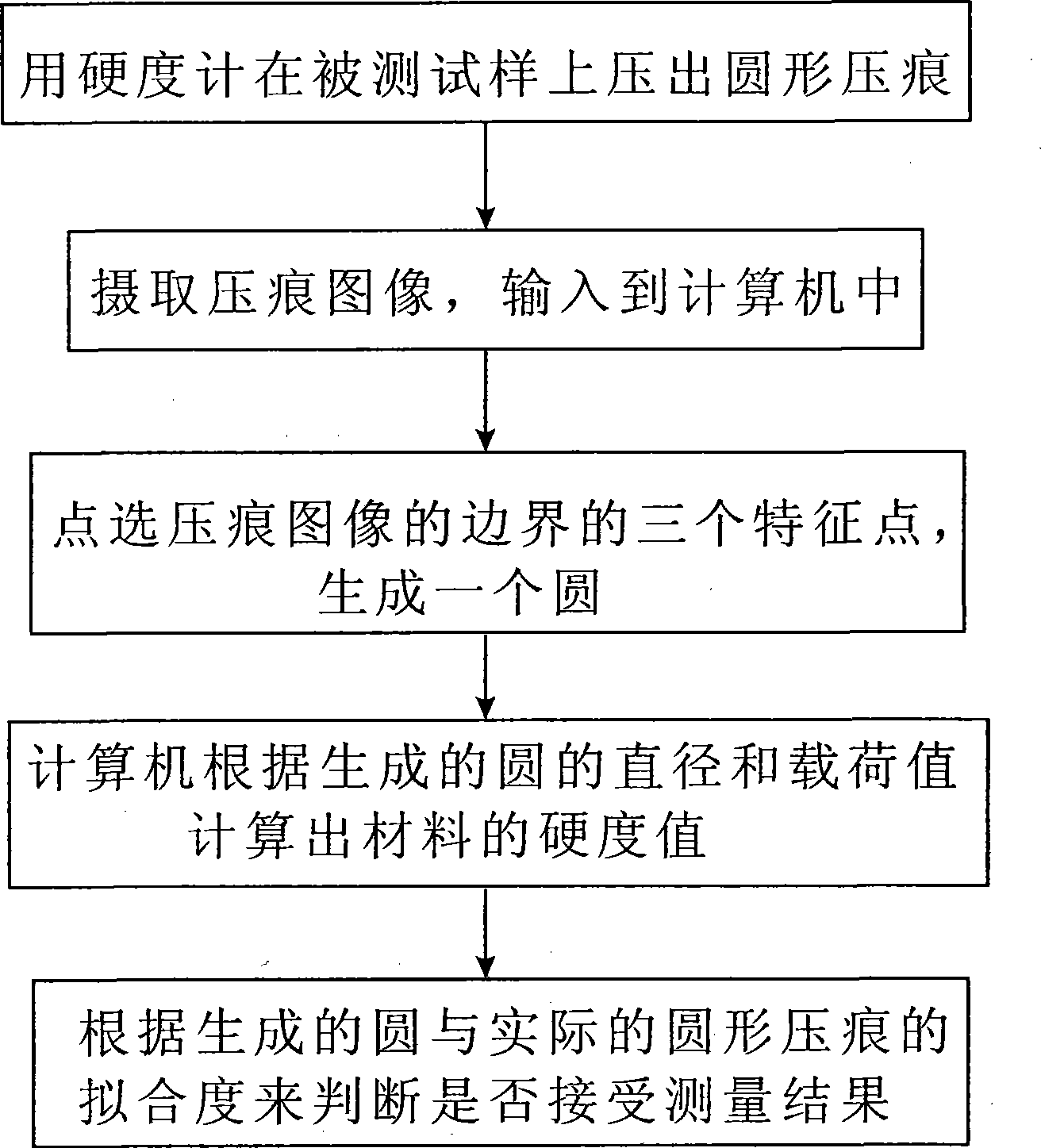

[0018] Such as figure 1 Shown, a kind of Brinell hardness measuring method of the present invention comprises the following steps:

[0019] First, apply a load to the tested sample with a hardness tester, and make a circular indentation on the tested sample.

[0020] Then, the indentation image is captured by a measuring microscope with a digital camera, and input into a computer programmed with a measuring program. When taking the indentation image, in order to make the image quality good and the boundary of the indentation image clear, a ring light is used for illumination.

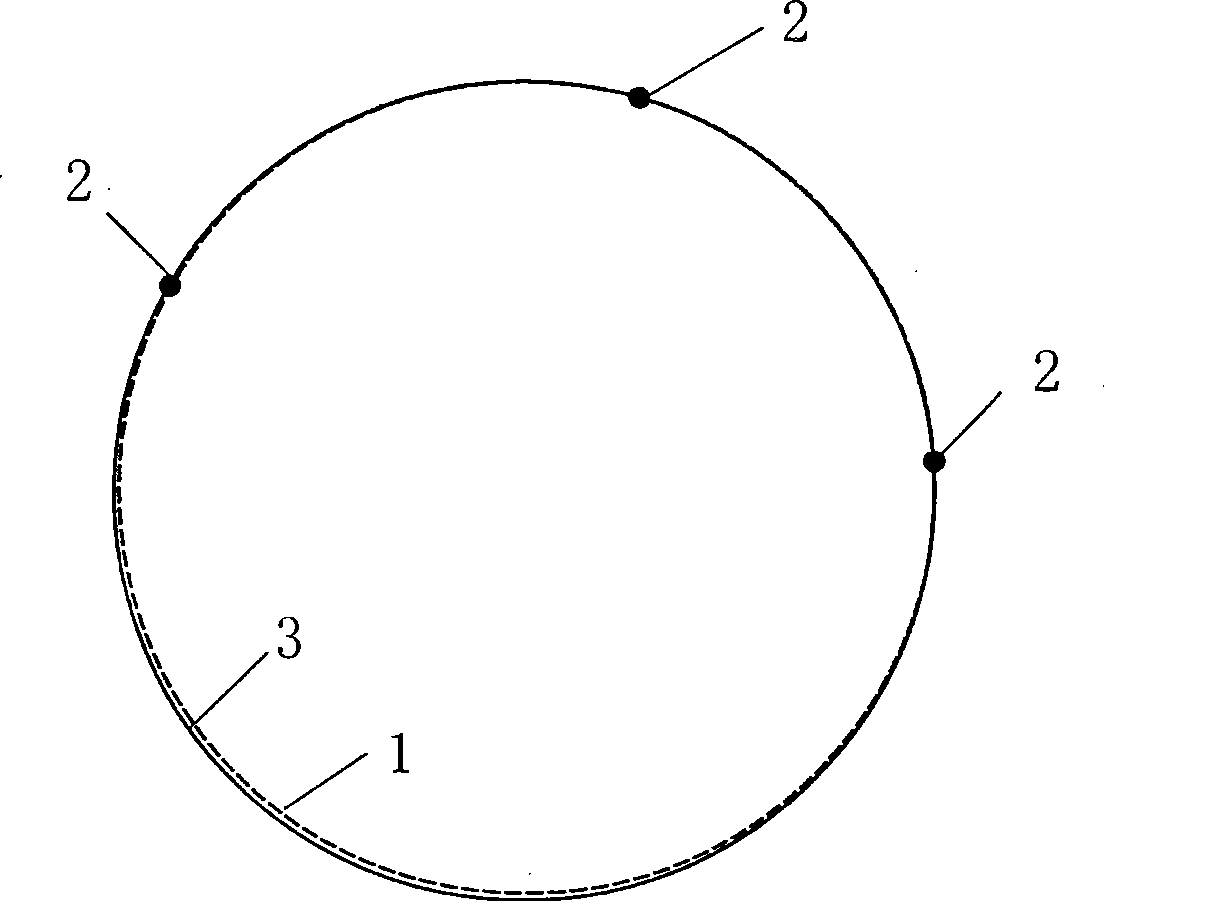

[0021] Then, in the computer, such as figure 2 As shown, three feature points 2 are selected along the boundary 1 of the indentation image, and a circle 3 is automatically generated by the computer using the principle of three points forming a circle.

[0022] Finally, the computer calculates the hardness value of the tested sample according to the diameter of the generated circle and the input load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com