Method for printing by operating printer

A technology of a printer and a printing program, which is applied to instruments, electrical recording technology using charge graphics, and equipment using electrical recording technology using charge graphics. The effect of time and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly illustrate the spirit of the present invention with illustrations and detailed descriptions. After those skilled in the art understand the embodiments of the present invention, they can be changed and modified by the technology taught in the present invention, which does not depart from the present invention. spirit and scope.

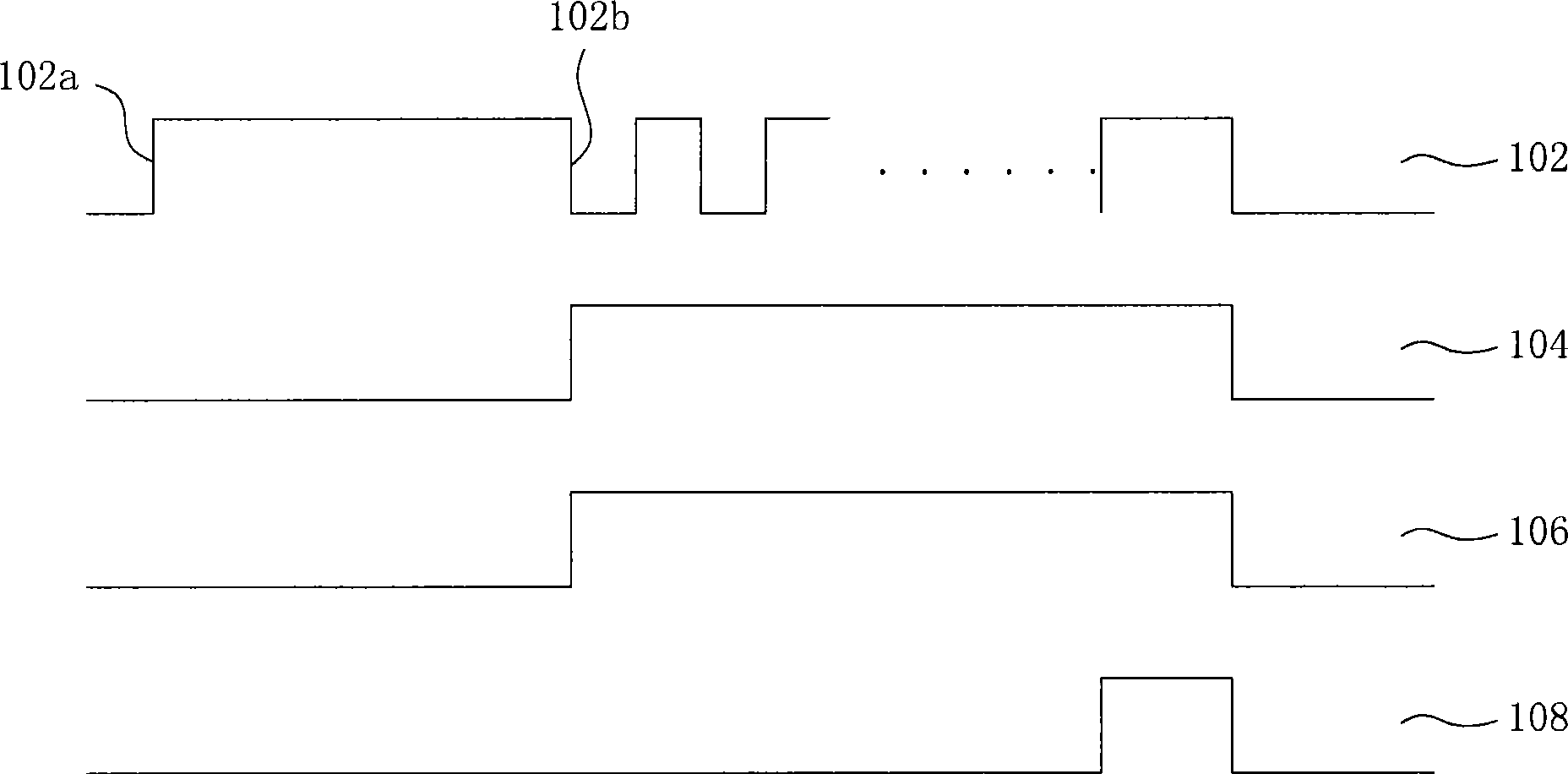

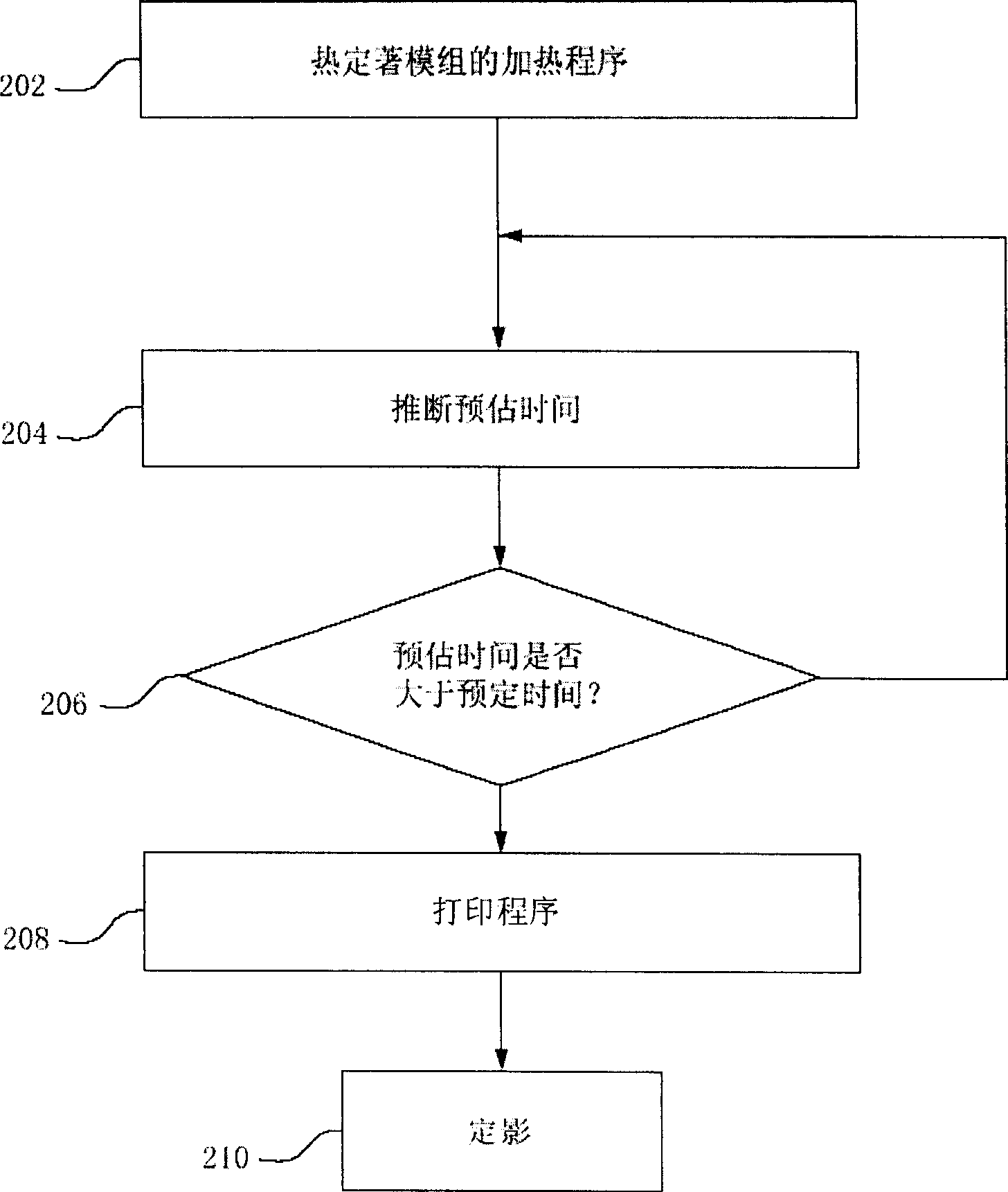

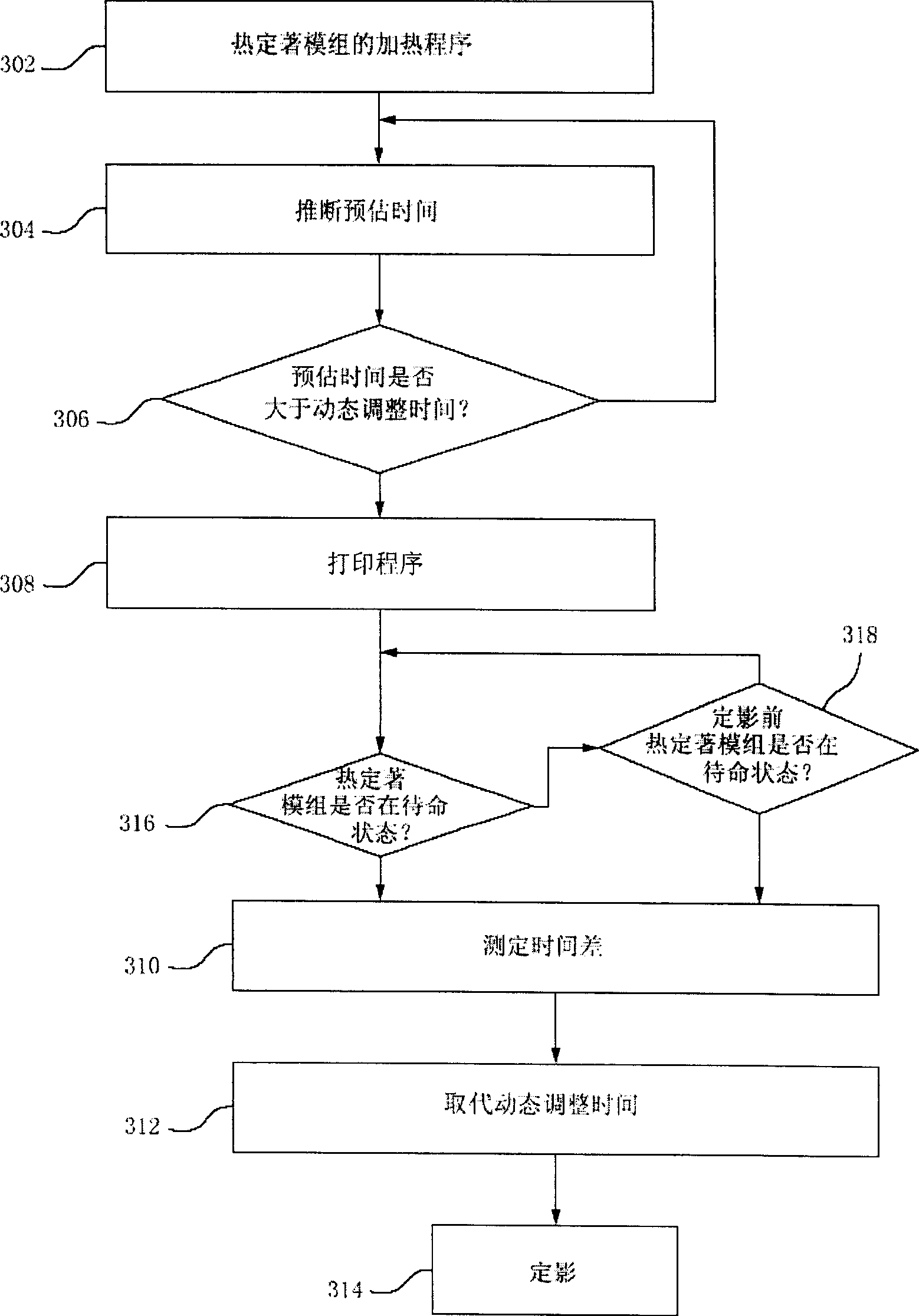

[0033] Please refer to figure 2 , which is a flowchart illustrating a printing process according to a first embodiment of the present invention. First, in the heating process 202, the heat-fixing module is heated to the target temperature; then, when the heat-fixing module reaches the target temperature, the printer measures the real-time temperature and infers the estimated time, which is to infer the time from the real-time temperature to the target temperature time required, see figure 2 , the inferring step 204 is to apply an algorithm (such as a computer program) to calculate the time required to reach the tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com