Method in connection with a reel-up of a fibre-web machine

A fiber web machine and web technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of hindering the machine, increasing costs, blocking, etc., to reduce surface cracks and achieve a large amount of cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the drawings and descriptions associated with the drawings, the same reference numerals are used to denote parts corresponding to each other unless otherwise indicated.

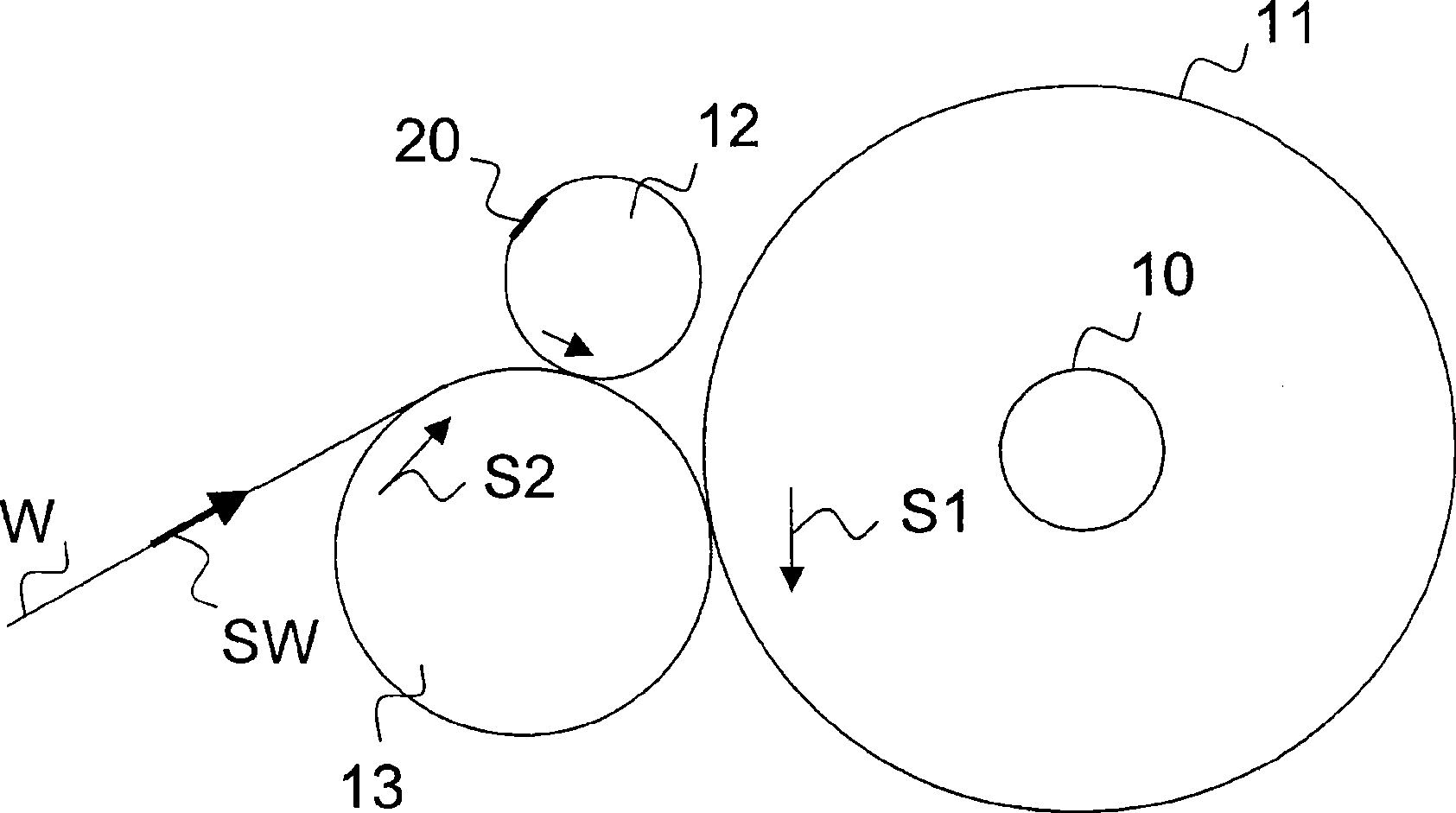

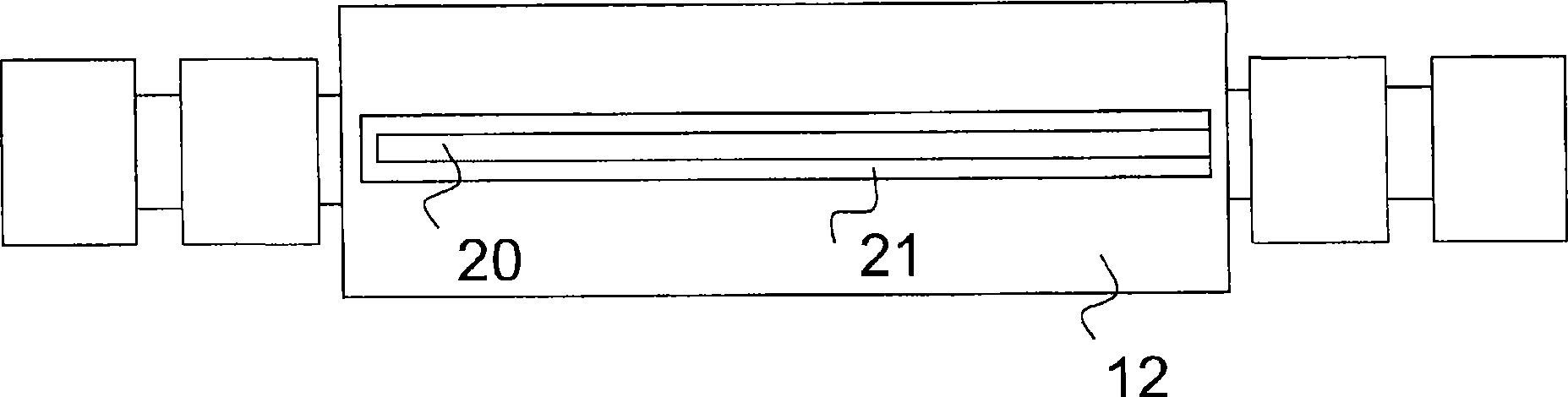

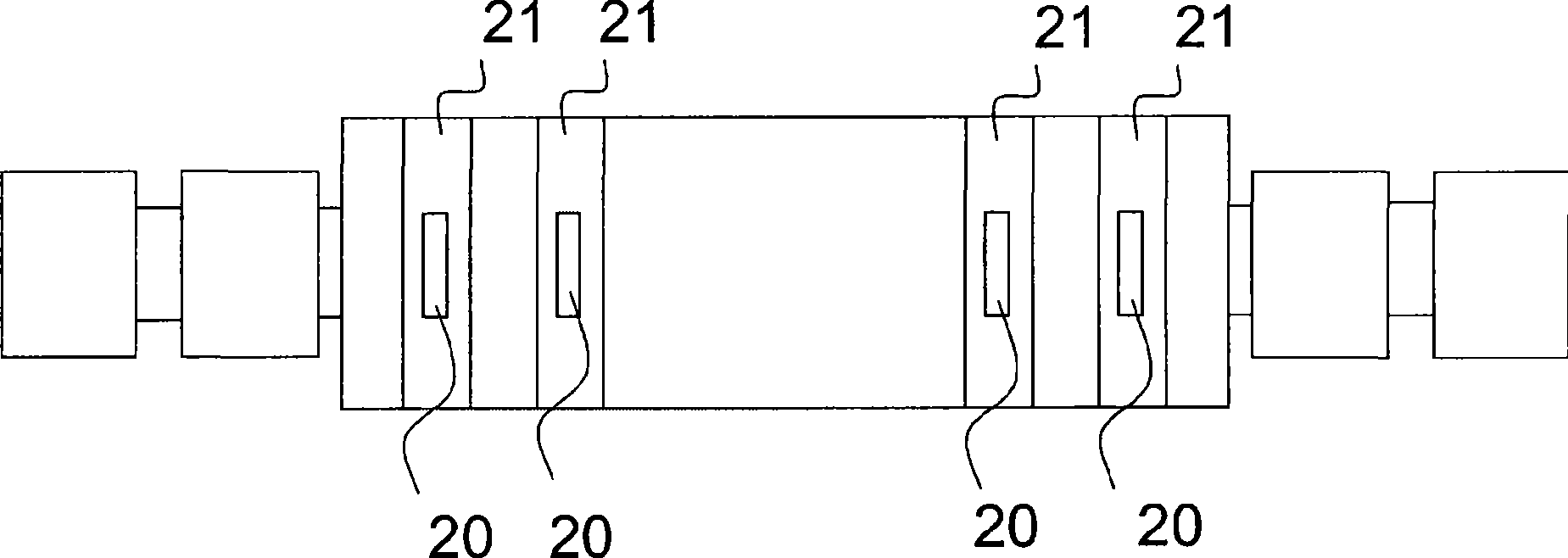

[0042] in accordance with figure 1 There is a web roll 11 in the arrangement, ie a fully wound machine roll 11 around the take-up shaft 10 . The reel is indicated with reference numeral 13 and in order to form the next web roll to be wound up on the new roll, the new take-up shaft 12 is moved to a standby position in relation to the reel 13 . Arrows S1 and S2 show the direction of rotation of the machine roll 11 being fully wound and the direction of rotation of the mandrel 13, and arrow SW shows the direction of travel of the web W. According to a preferred embodiment of the present invention, one or more double-sided adhesive tapes 20 are fixed to the surface of the new take-up shaft 12 to be moved to the standby position before the new take-up shaft 12 is moved to the standby position. Adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com