Neutron polarization equipment

A technology of neutrons and neutron beams, applied in the field of neutron polarization devices, can solve problems such as difficult polarization, and achieve high stability and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

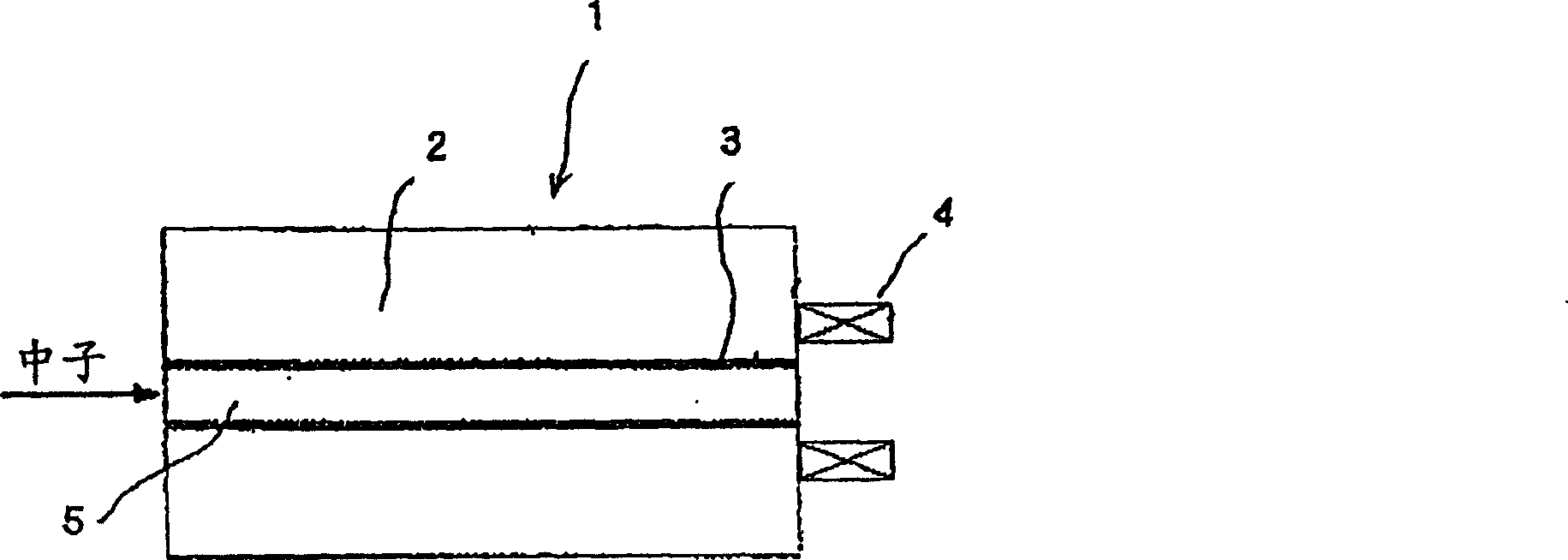

[0086] FIG. 5 is a schematic cross-sectional view showing the configuration of an experimental device using the neutron polarizer according to the embodiment of the present invention.

[0087] In FIG. 5 , 11 is a neutron polarizer, which includes a Halbach-type quadrupole magnet 12 (hereinafter also simply referred to as a quadrupole magnet 12 ). The length of the Halbach-type quadrupole magnet 12 in the axial direction is about 600 mm, and a cylindrical neutron-absorbing material (hereinafter, also referred to as a Cd tube) 13 composed of Cd is arranged inside it to form a hollow space for the passage of neutrons. part by diameter The form that becomes 5mm extends in the axial direction. The neutron absorbing material 13 is a material for preventing reflection of neutrons on the inner surface of the quadrupole magnet 12, and is formed by spirally winding a Cd plate with a thickness of 0.5 mm. On the downstream side end of the quadrupole magnet 12, a magnetic field connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com