Tooth grinder for producing bimetal band saw blade

A bi-metal belt and gear grinding machine technology, applied in metal sawing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of non-conforming production requirements, low production efficiency, low precision and smoothness, etc. Production efficiency, improved quality, high finish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

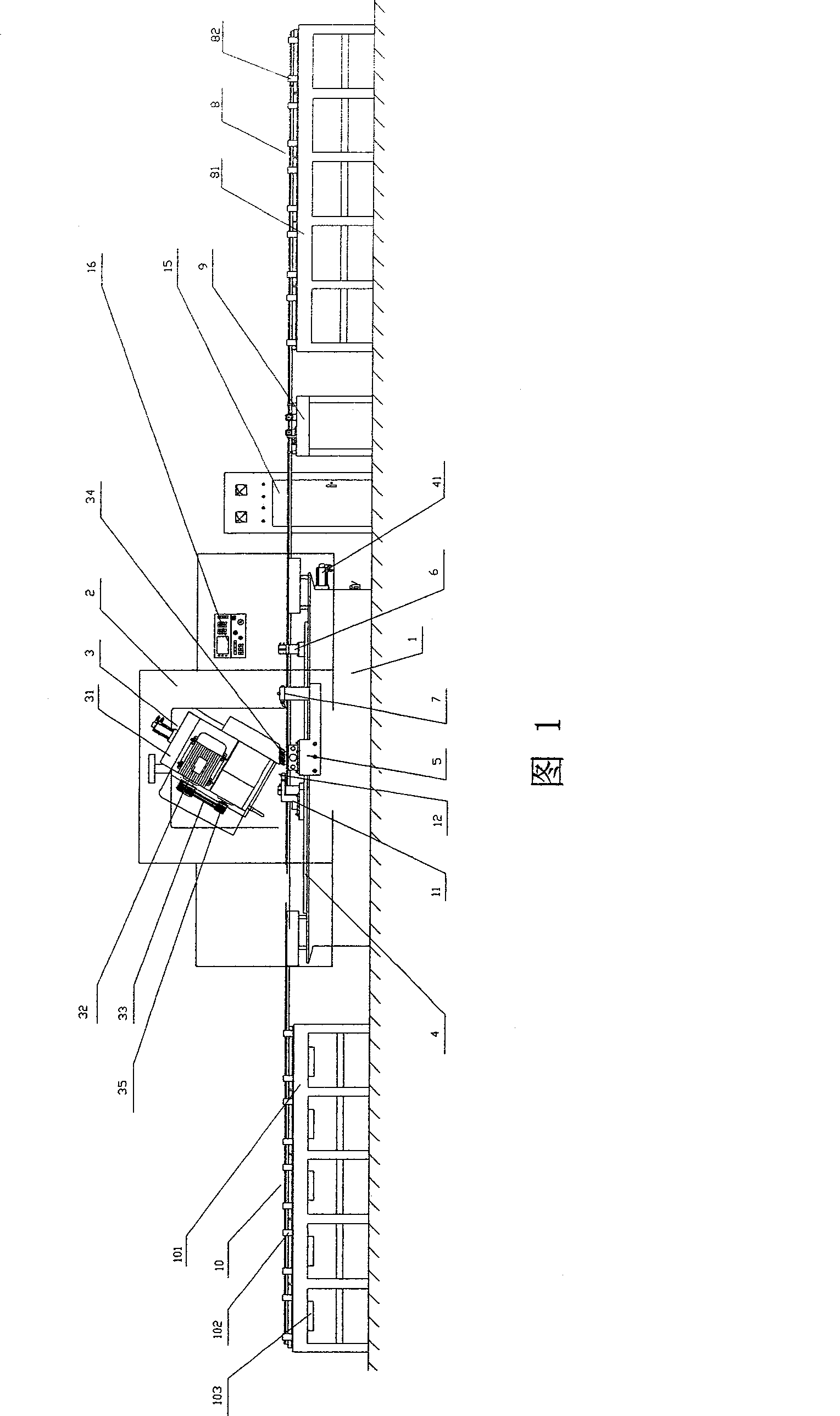

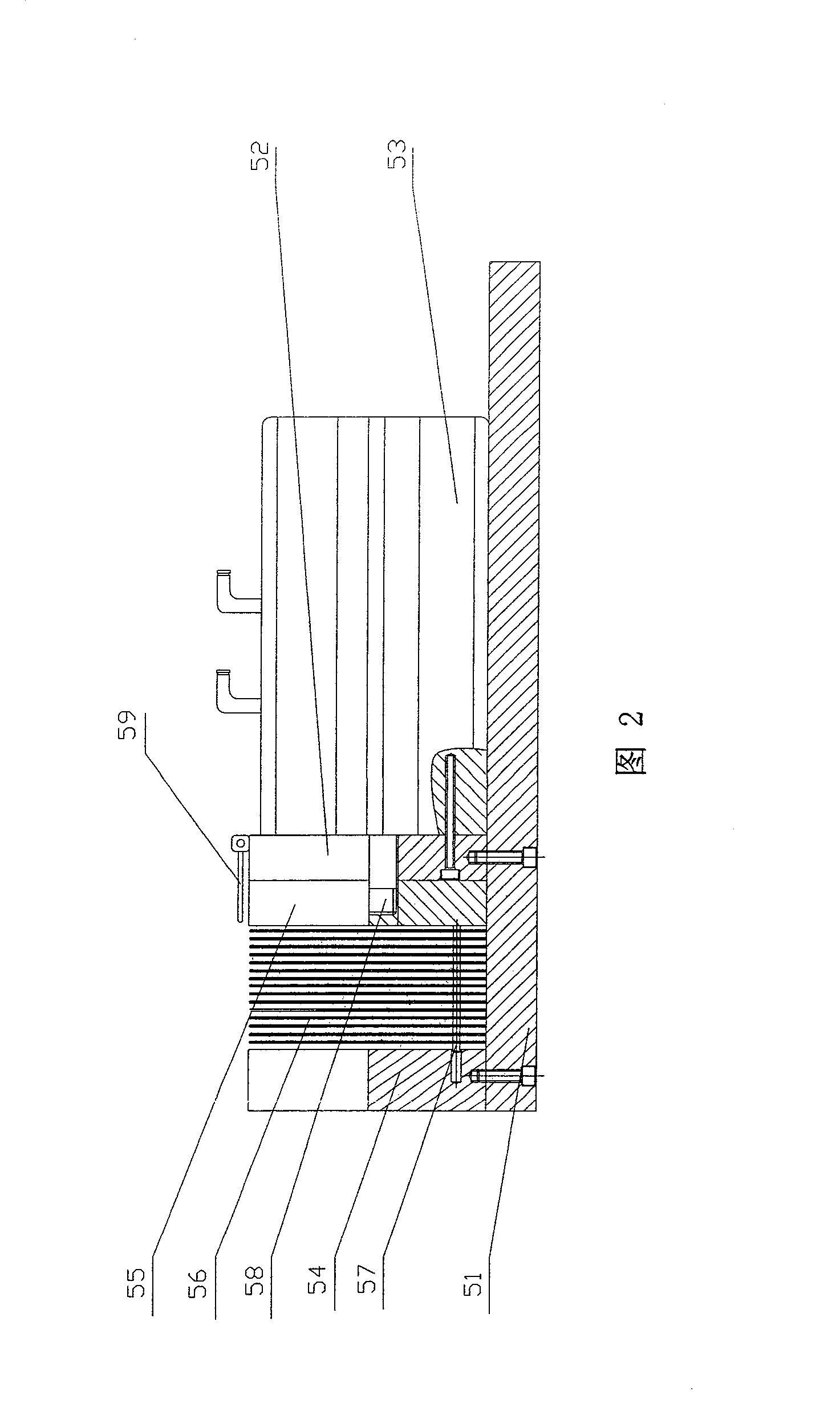

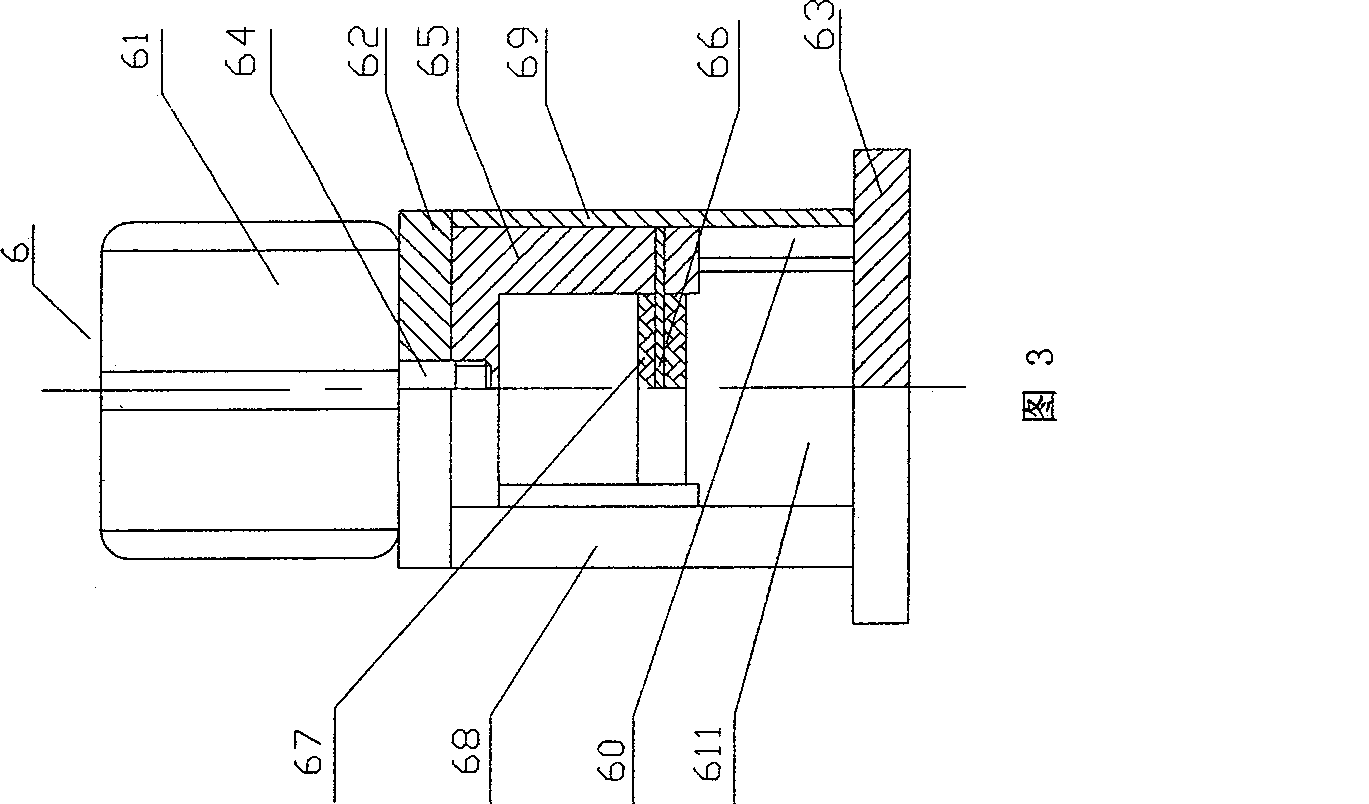

[0022] As shown in Figure 1, the present invention comprises machine tool base 1, is provided with machine tool cover 2 on the top of machine tool base 1, is provided with grinding wheel driving device 3 in machine tool housing 2, and this grinding wheel driving device 3 comprises body 31, on body 31 A motor 32 and a grinding wheel 34 with a drive shaft 35 are installed, the motor 32 is connected with the drive shaft 35 by a belt 33, the angle between the grinding wheel 34 and the machine base 1 is set at 60 degrees, and the grinding wheel 34 is a truncated cone. And the side of emery wheel 34 is serrated, is provided with the X-axis slide block 4 that can slide left and right on machine tool base 1, and X-axis slide block 4 is controlled by the motor 41 that is installed on the machine tool base 1, and X-axis slide block 4 is connected with Clamping workbench 5, as shown in Figure 2, this clamping workbench 5 comprises cylinder 51, the cylinder fixing plate 57 of fixing cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com