Pipe shaped sponges shaping conjunction machine

A sponge and tube-shaped technology, which is applied in the field of tube-shaped sponge forming and fitting machines, can solve problems such as production line capacity not meeting requirements, product reliability being low, wire loss of protection, etc., achieving easy disassembly and repair, high degree of automation, and production fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

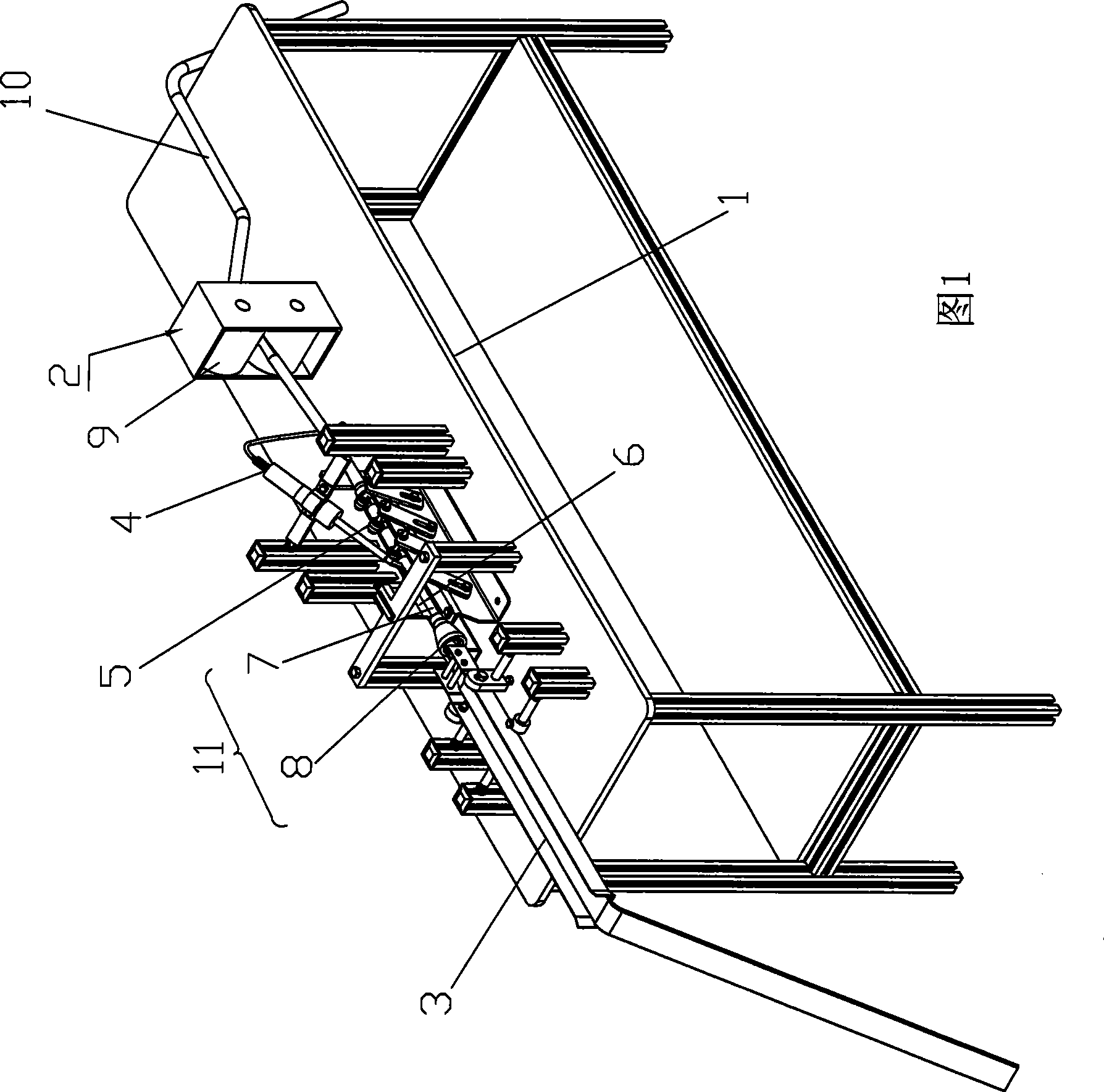

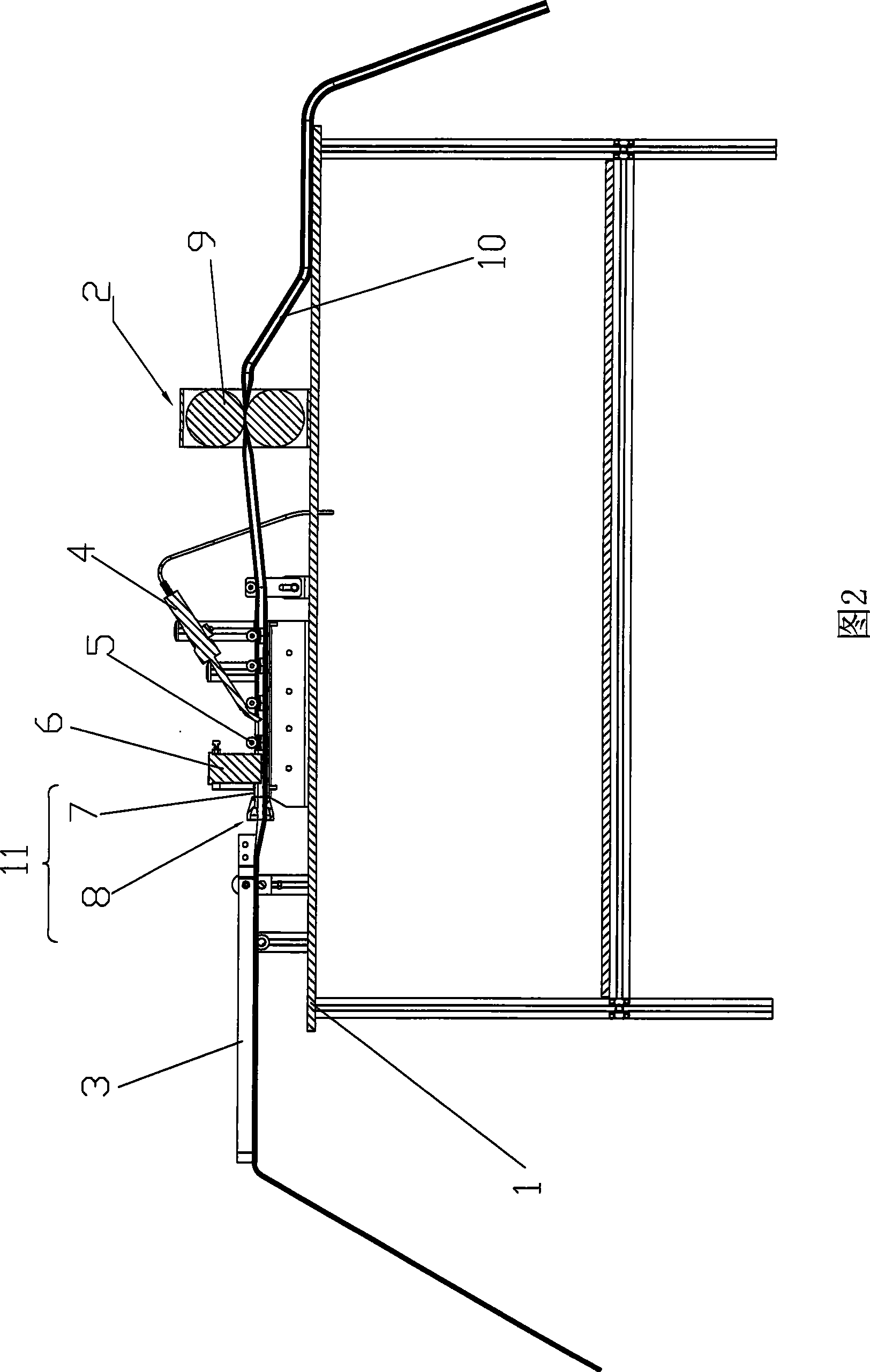

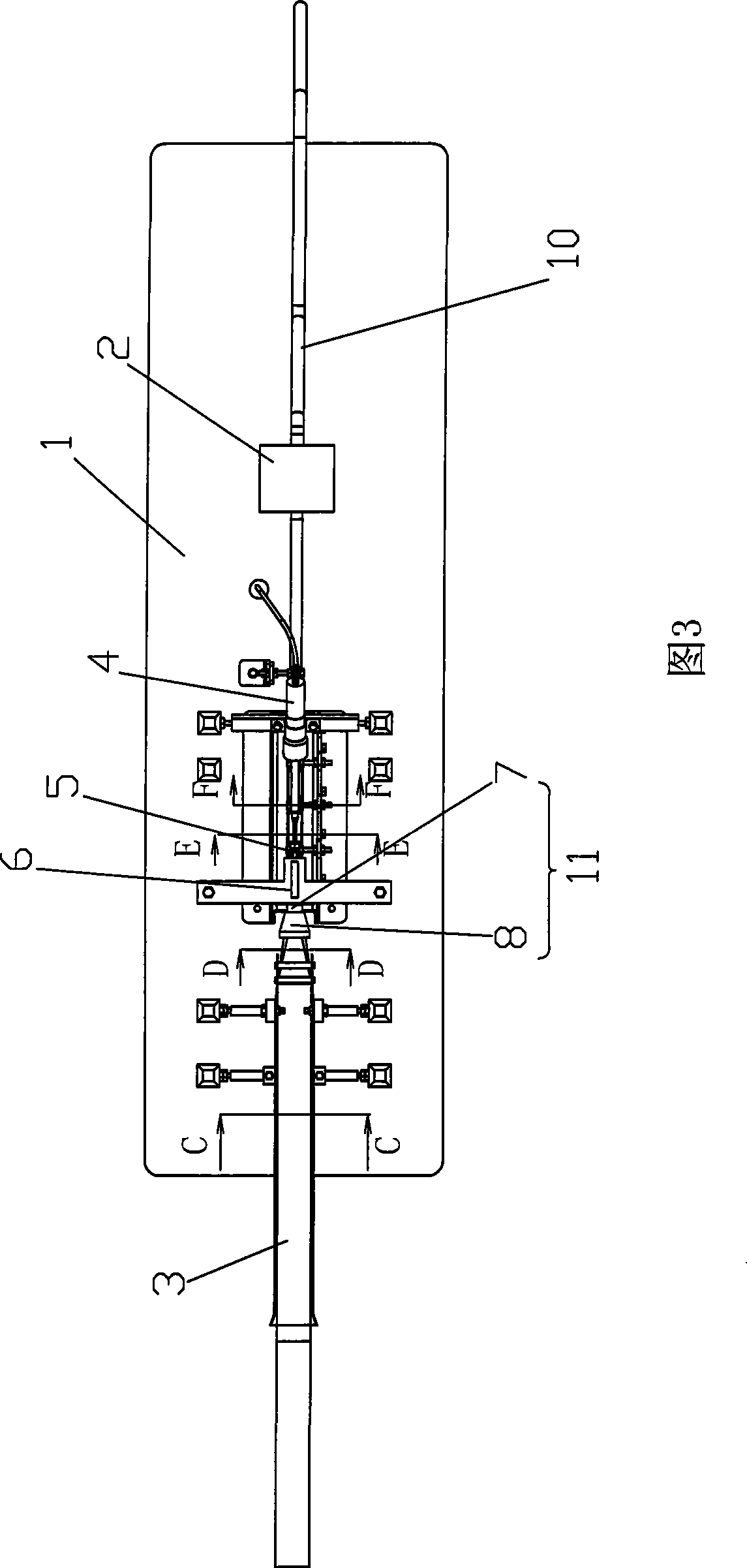

[0017] See Figure 1 to Attached Figure 7 , a tubular sponge forming and fitting machine, which includes: a frame 1, a throat-shaped tube 11 arranged on the frame 1 from back to front, at least partially extending into the throat-shaped tube 11 guide plate 6, electric soldering iron 4, and traction mechanism 2 for pulling the sponge tube, as shown in the figure, the traction mechanism 2 includes two rollers 9 with opposite directions of rotation, and the processed tubular sponge 10 is positioned between the two rollers. Pass between 9, rely on a pair of rollers 9 to constantly pull the sponge 10 forward, so that the strip sponge in the feeding position moves forward along the feeding guide rail 3. In accompanying drawing 2, the right side is before, and the left side is after.

[0018] In this embodiment, the throat-shaped pipe 11 includes a circular tube 8 whose diameter gradually decreases from the rear to the front and a circular tube 7 connected to the front end of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com