Printing-plate adjustment embossment decorating paper printing method

A printing method and decorative paper technology, applied in printing, decorative art, printing technology, etc., can solve the problems of undiscovered materials, etc., and achieve the effect of improving the decoration level, rich layers, and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

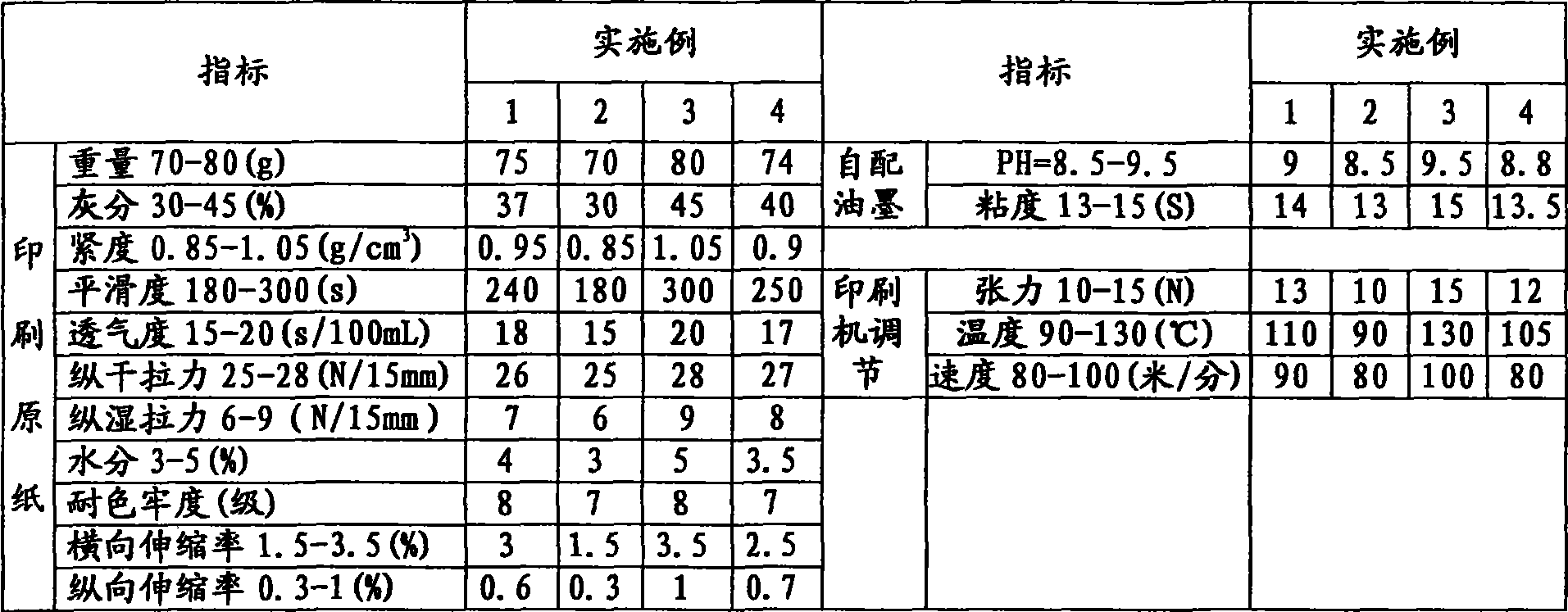

[0013] Embodiment 1 (referring to embodiment 1 index value in the table): the weight of selection printing base paper for decoration is 75g paper, ash content 37%, tightness 0.95g / cm 3 , smoothness 240 seconds (s), air permeability 18 seconds / 100mL, vertical dry tensile force 26 Newtons / 15mm, longitudinal wet tensile force 7 Newtons / 15mm, moisture 4%, compared with blue wool color fastness of 8 grades, horizontal The expansion rate is 3%, and the longitudinal expansion rate is 0.6%. After the printing base paper is selected, water-based inks are purchased, and the three primary colors, black inks and diluents (thinners) of the specified codes are purchased from Taiwan Great World Company. If you want to simulate the light yellow sandalwood board, take a photo of the sandalwood board pattern, computer engrave the recording roller, and then use yellow 5120 ink and thinner 100 to make light yellow water-based ink, put it in the color tank of the printing machine, and prepare The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com