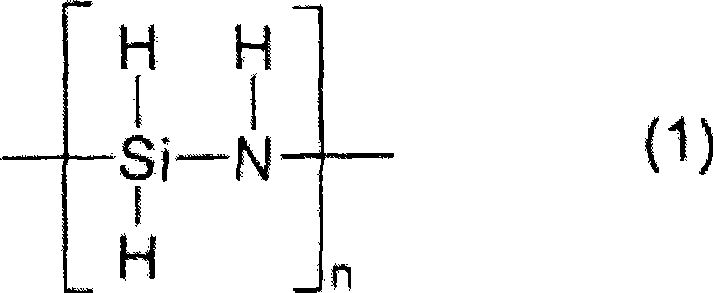

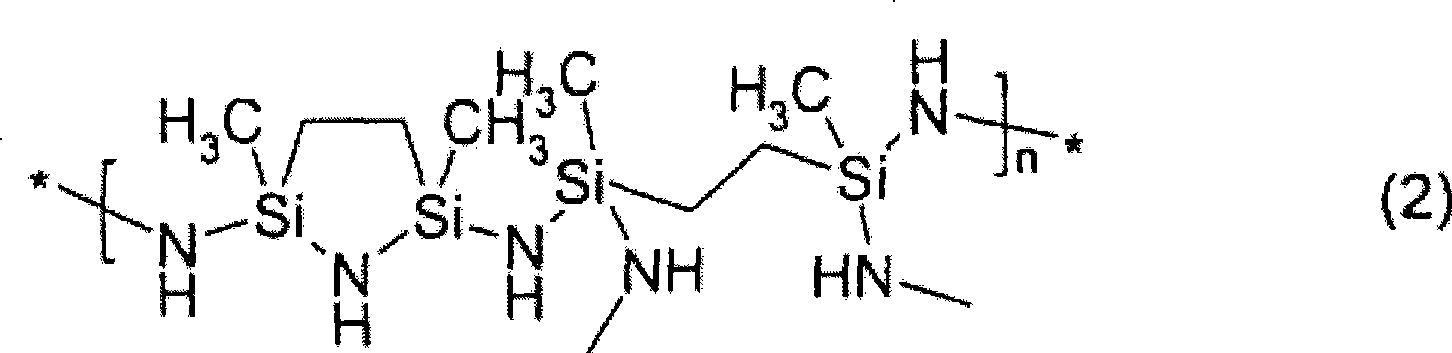

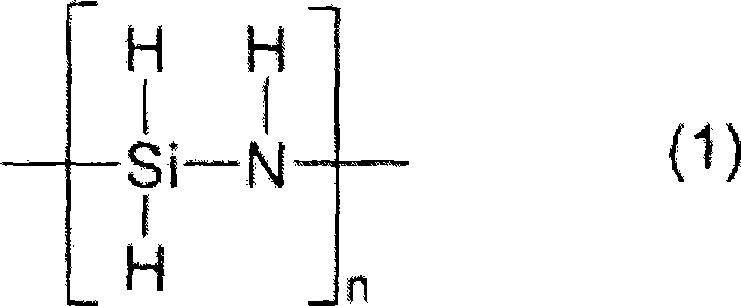

Coatings comprising polysilazanes for preventing scaling and corrosion

A polysilazane and coating technology, applied in the field of polysilazane-based coatings, can solve the problems of consumption, large materials, high roasting temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] V2A sheets (steel 1.4301, X5 CrNi 1810 / Cr 18%, Ni 10%, Si 1%, Mn 2%, P 0.045%, S 0.03%, C<0.07%, the rest is Fe) for coating. After drying at room temperature (about 30 min), the coated sheets were stored in air in an oven to 1000° C. for 1 h, the rate of heating and cooling was 3 K / min.

[0039] The oxidation test can be repeated several times without observed fouling of the steel.

Embodiment 2

[0041] V2A sheets (steel 1.4301, X5 CrNi 18 10 / Cr 18% , Ni 10%, Si 1%, Mn 2%, P 0.045%, S 0.03%, C<0.07%, and the rest is Fe) for coating. After drying at room temperature (approximately 30 min), the coated sheets were stored in air in an oven to 1000° C. for 10 h, with a heating and cooling rate of 5 K / min.

[0042] The oxidation test can be repeated several times without observed fouling of the steel.

Embodiment 3

[0044] V2A sheets (steel 1.4301, X5Cr Ni 18 10 / Cr 18%, Ni 10%, Si 1%, Mn 2%, P 0.045%, S 0.03%, C<0.07%, and the rest is Fe) for coating. After drying at room temperature (about 30 min), the coated sheets were stored in air in an oven to 1000° C. for 10 h, the rate of heating and cooling was 3 K / min.

[0045] The oxidation test can be repeated several times without observed fouling of the steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com