Gravity centre adjustment mechanism for spreader

A center of gravity adjustment, paver technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of increasing construction costs, time-consuming and labor-intensive paving of variable-path roads, road indentation, etc., and achieves the effect of convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

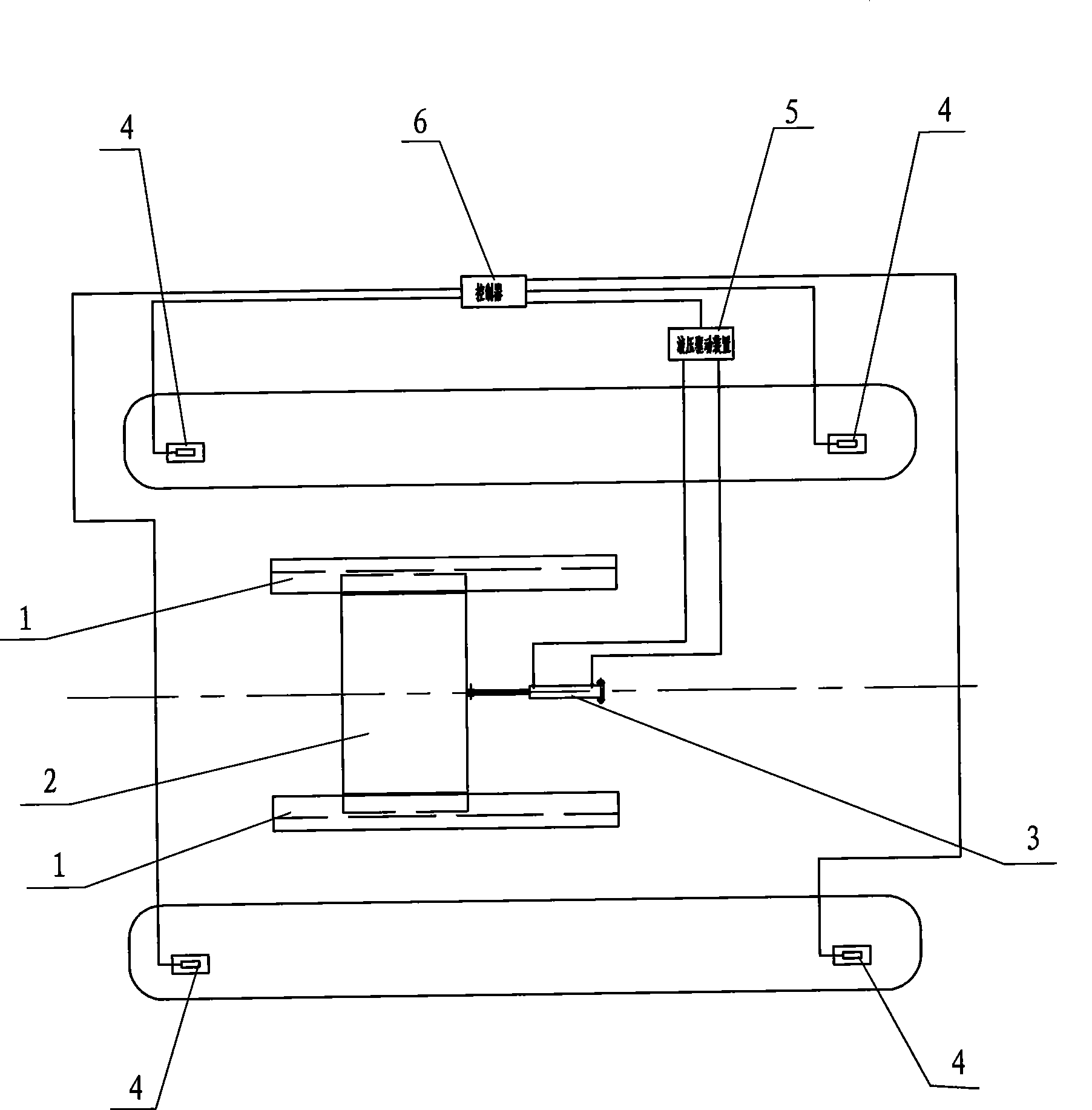

[0008] In the embodiment shown in the figure, a slide rail 1, a counterweight 2 and a hydraulic cylinder 3 are installed on the chassis of the paver, pressure sensors 4 distributed on the crawler belt of the paver, and hydraulic pressure sensors 4 are installed on the machine body. Drive device 5 and controller 6. During the operation, when the center of gravity of the paver changes, the detection values of each pressure sensor 4 also change accordingly. The controller 6 makes a judgment after receiving the sensing signals of each pressure sensor, and then through the hydraulic drive The cylinder 3 drives the counterweight 2 to move, thereby realizing the adjustment of the center of gravity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com