Solar water heating system with leakage proof function

A technology of solar water heating and anti-running water, which is applied in the field of solar water heating systems, can solve problems such as waste of water resources, and achieve the effect of ensuring normal operation and preventing running water problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

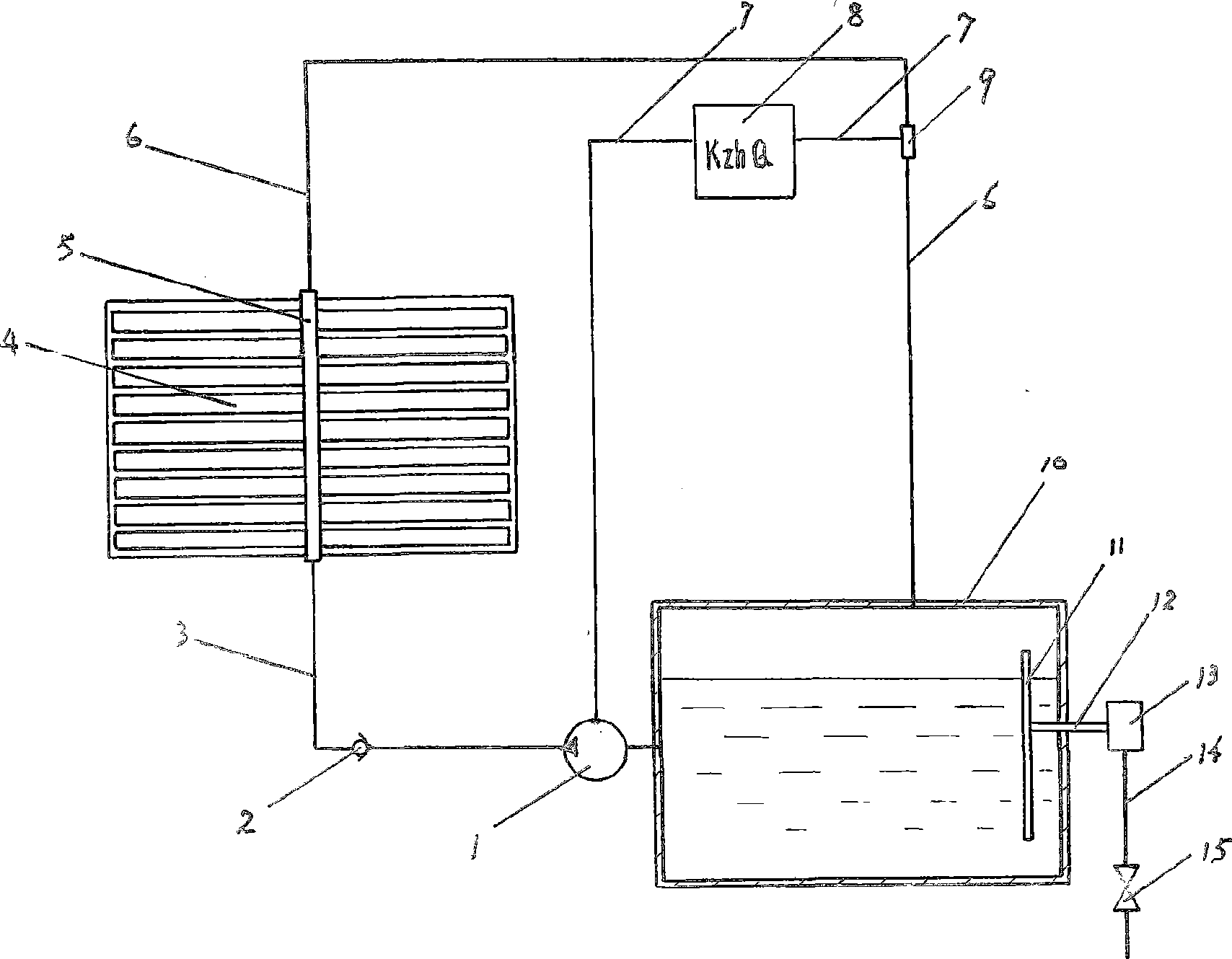

[0014] Embodiment 1 (see figure 1 ):

[0015] exist figure 1 Among them, the installation position of the water storage tank 10 is lower than the installation position of the all-glass vacuum heat collecting tube 4.

[0016] This embodiment includes a water storage tank 10, an all-glass vacuum heat collecting tube 4, a heat collecting coupler 5, a heat collecting circulation pump 1, an automatic controller 8, a water level controller 13 for replenishing water to the water storage tank, and a one-way valve 2; automatic control The output terminal of instrument 8 controls the on-off of the power supply of heat collecting circulation pump 1 and solenoid valve 16 respectively; The output terminal is connected to the corresponding input terminal of the automatic controller 8 .

[0017] The liquid level sensor adopts a special water flow switch 9 whose output is a pulse signal, and the water flow switch 9 is installed on the heat collection and return water circulation pipeline 6...

Embodiment 2

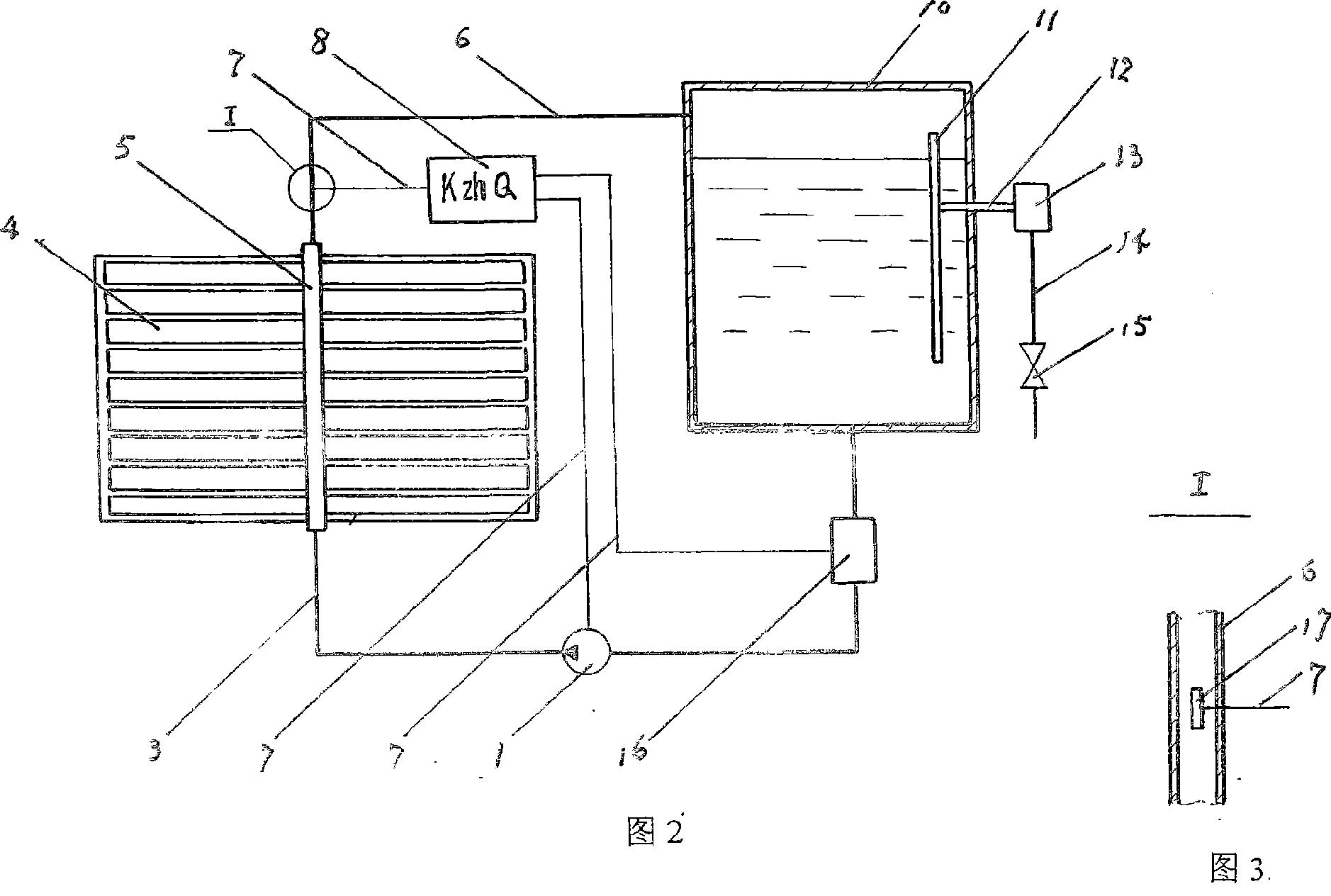

[0021] Embodiment 2 (seeing Fig. 2,3):

[0022] Embodiment 2 differs from Embodiment 1 in that there are two points. The first point is that the installation position of the water storage tank 10 is higher than the installation position of the all-glass vacuum heat collection tube; Check valve 2, but solenoid valve 16. The liquid level sensor adopts a special liquid level sensor 17 whose output signal is a switch signal, and the special liquid level sensor 17 is installed at the highest point position of the heat collection and return water circulation pipeline 6; the output terminal of the special liquid level sensor 17 is connected to The corresponding input terminal of the automatic control instrument 8.

[0023] In this embodiment, when the special liquid level sensor 17 is short of water, the special liquid level sensor 17 outputs a switch signal to the automatic controller 8, and the automatic controller 8 outputs two instruction signals, and one instruction signal goes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com