Active pay-off machine device

A pay-off machine, active technology, used in transportation and packaging, insulation of conductors/cables, electrical components, etc., can solve the problems of increasing the tension of the inner core of the cable, troublesome equipment adjustment, insensitive induction methods, etc. Sensitivity, sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

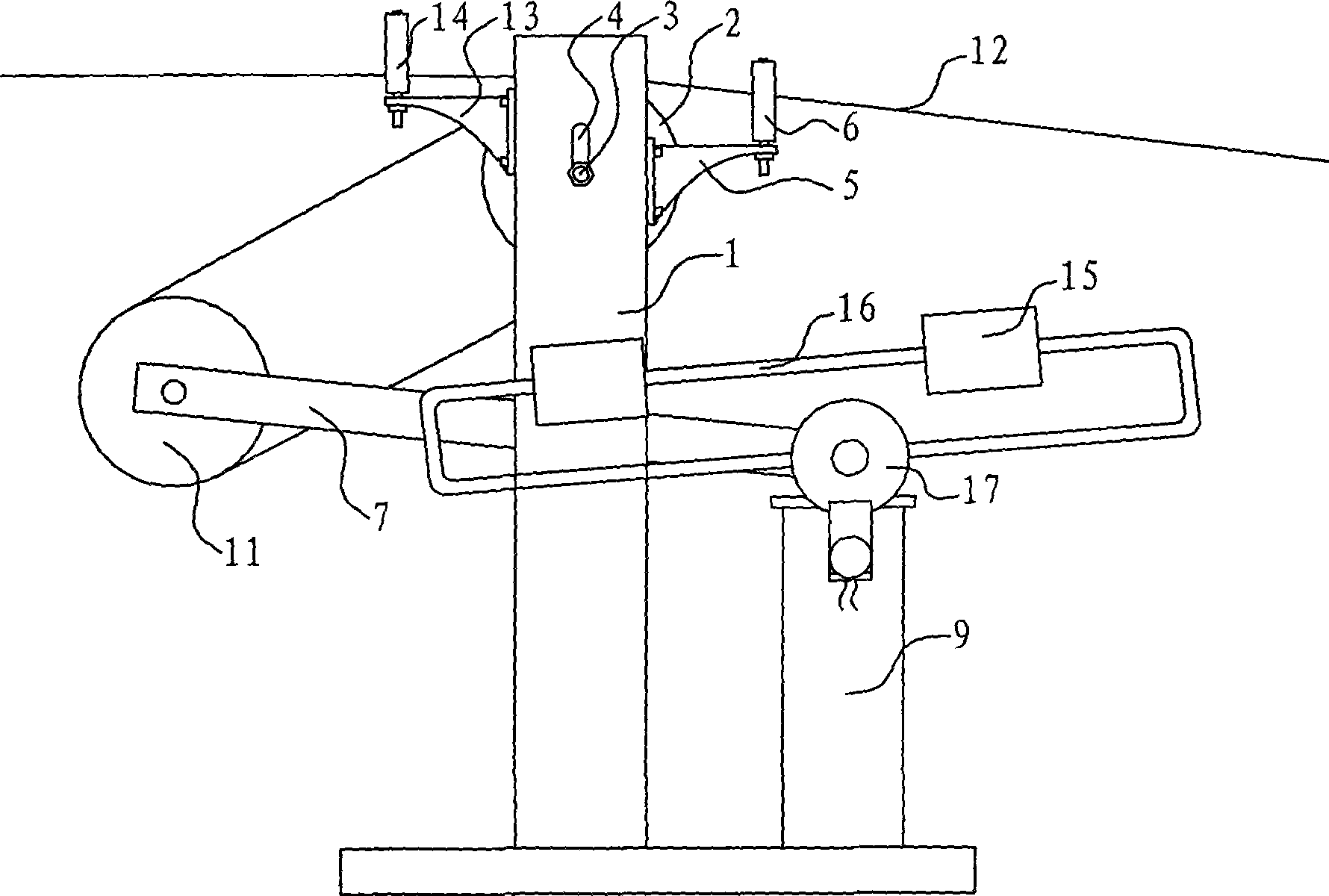

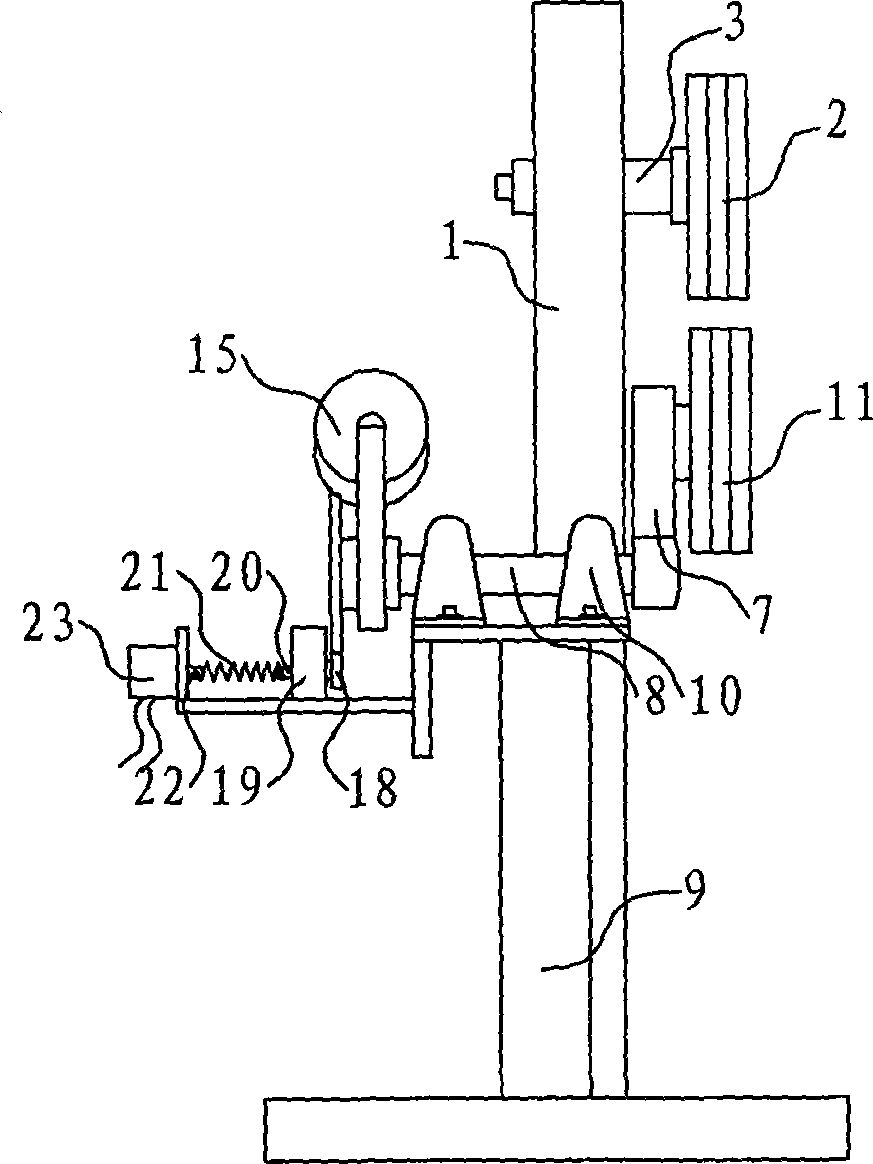

[0025] The active pay-off machine device of the present invention includes a control device for controlling the rotational speed of a motor, a wire reel wound with a cable inner core driven by the motor, and a tension adjusting device.

[0026] The tension adjusting device comprises a frame 1 and a frame 9, a fixed wheel 2 fixed on the frame 1, a rocker 7 hinged with the frame 9, a moving wheel 11 fixed on the swing end of the rocker 7, and a swinging wheel for sensing the swing of the rocker 7. Amplitude sensor 23 . Frame 1 and frame 9 can be made into an integral or split structure.

[0027] The wire reel is fixed on one side of the tension adjusting device through an axial clamp, and the signal line of the sensor 23 of the tension adjusting device is connected to the control device of the wire reel.

[0028] Such as figure 1 In the tension adjusting device of the active pay-off machine shown, a rotatable fixed wheel 2 is fixed on the upper part of the frame 1 . The centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com