Cold rolled aluminum belt on-line oil baffling, removing equipment

A kind of equipment, technology of aluminum plate, applied in the field of aluminum processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

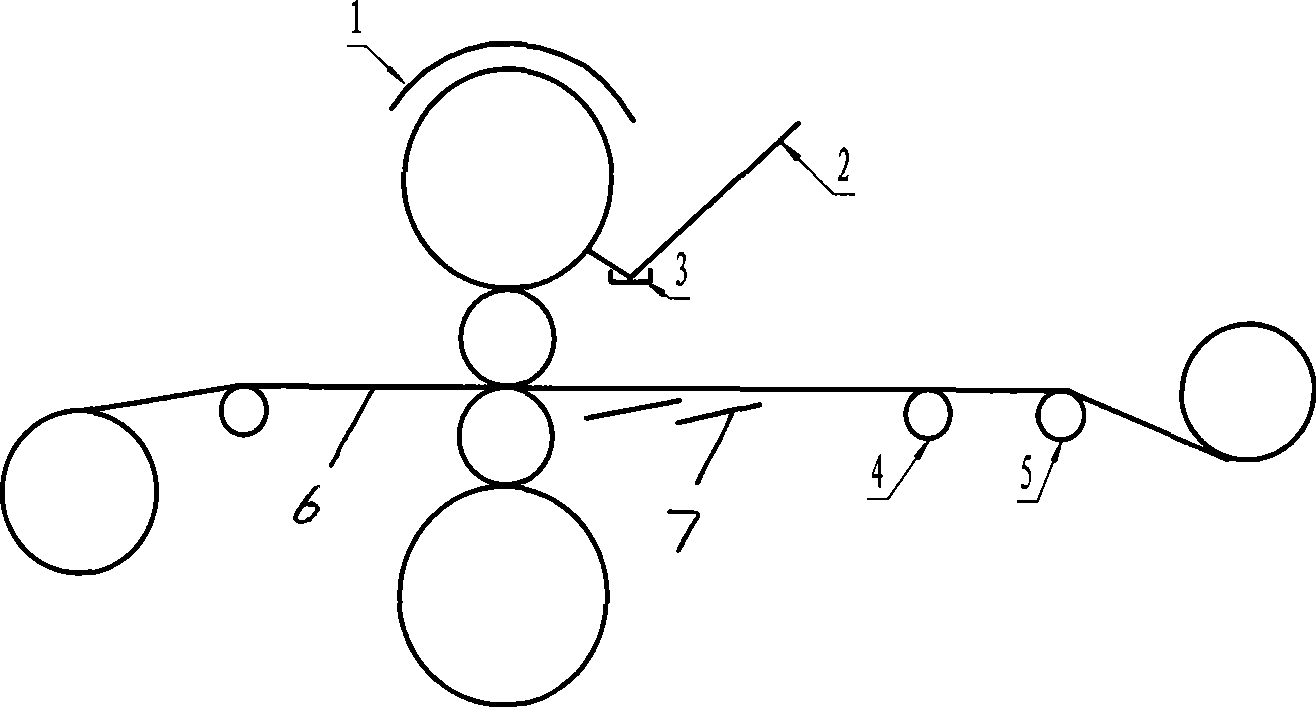

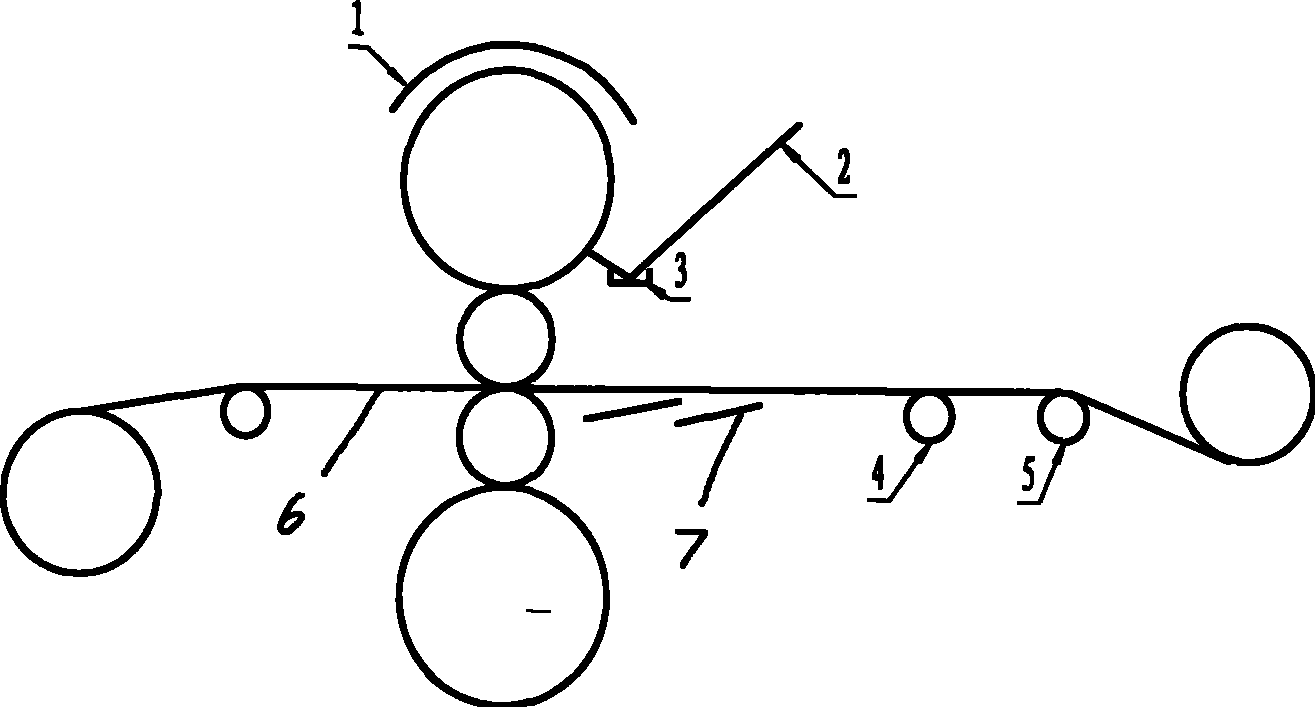

[0013] 1. In terms of equipment: such as figure 1 As shown, install an arc-shaped oil deflector 1 above the upper support roller; install an easy-to-disassemble oil deflector 3 at the bottom of the air roller cleaner 2; punch some holes of different shapes and sizes on the outlet guide 7, Add a deflector roller 4 between the outlet deflector roller 5, and leave a distance of 300-400 millimeters between the two deflector rollers, so that a vacuum blowing and sucking device (existing device) can be installed to remove part of the high-temperature oil mist suck away.

[0014] 2. In terms of technology: ① Improve the rolling line, and the rolling mill can increase the adjustment space of 0-20 mm, reducing the chance of contact between the aluminum plate and the rolling oil on the outlet guide plate; ② Properly adjust the vacuum blowing oil suction device to purge the plate surface according to the plate width The angle and distance of the air nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com