Shape adjusting apparatus for digital control flexible fixture

A shape-adjusting and flexible technology, which is applied in the field of CNC flexible frame shape-adjusting devices, can solve problems such as the non-adjustable lugs, and achieve the effects of simple and reliable structure, increased rigidity, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

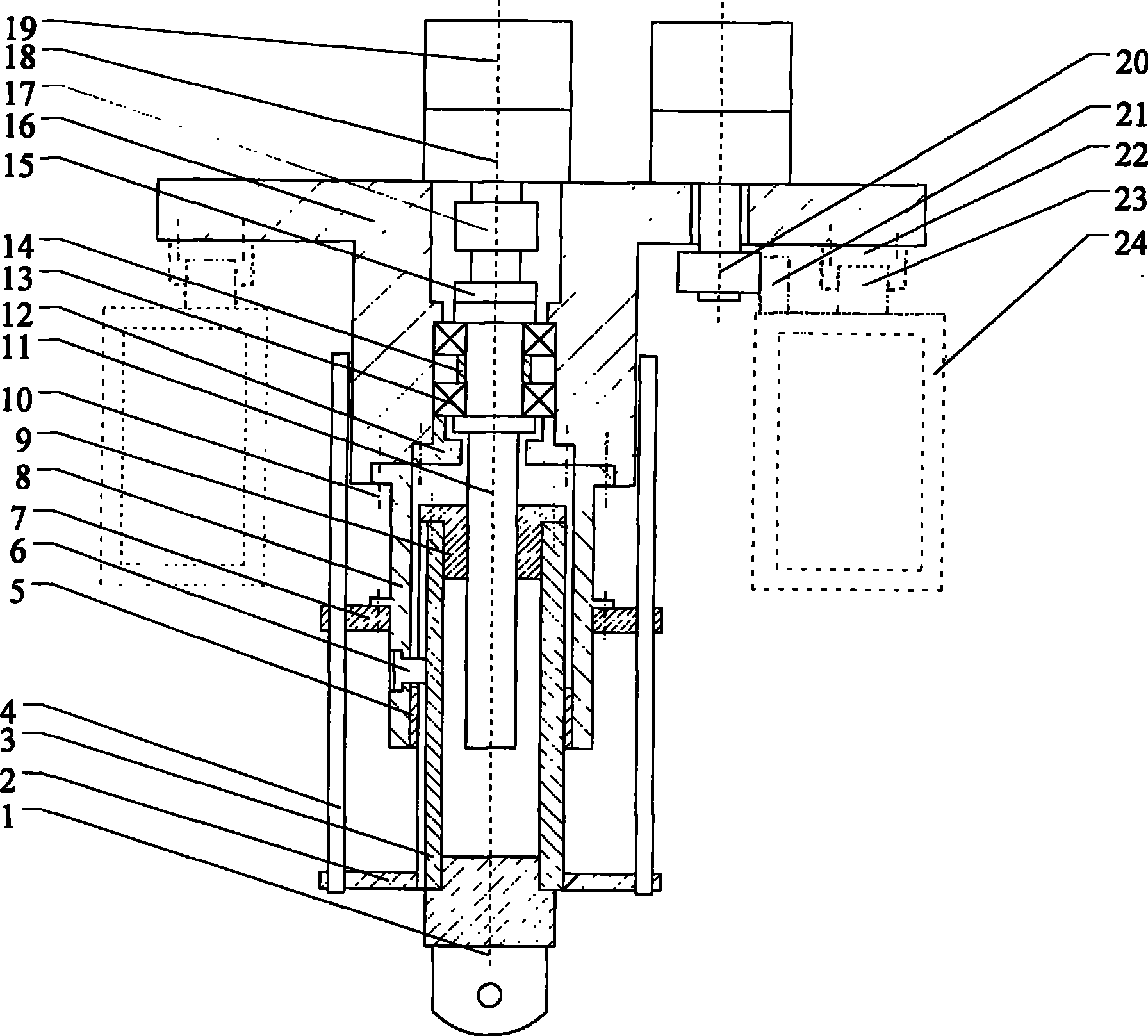

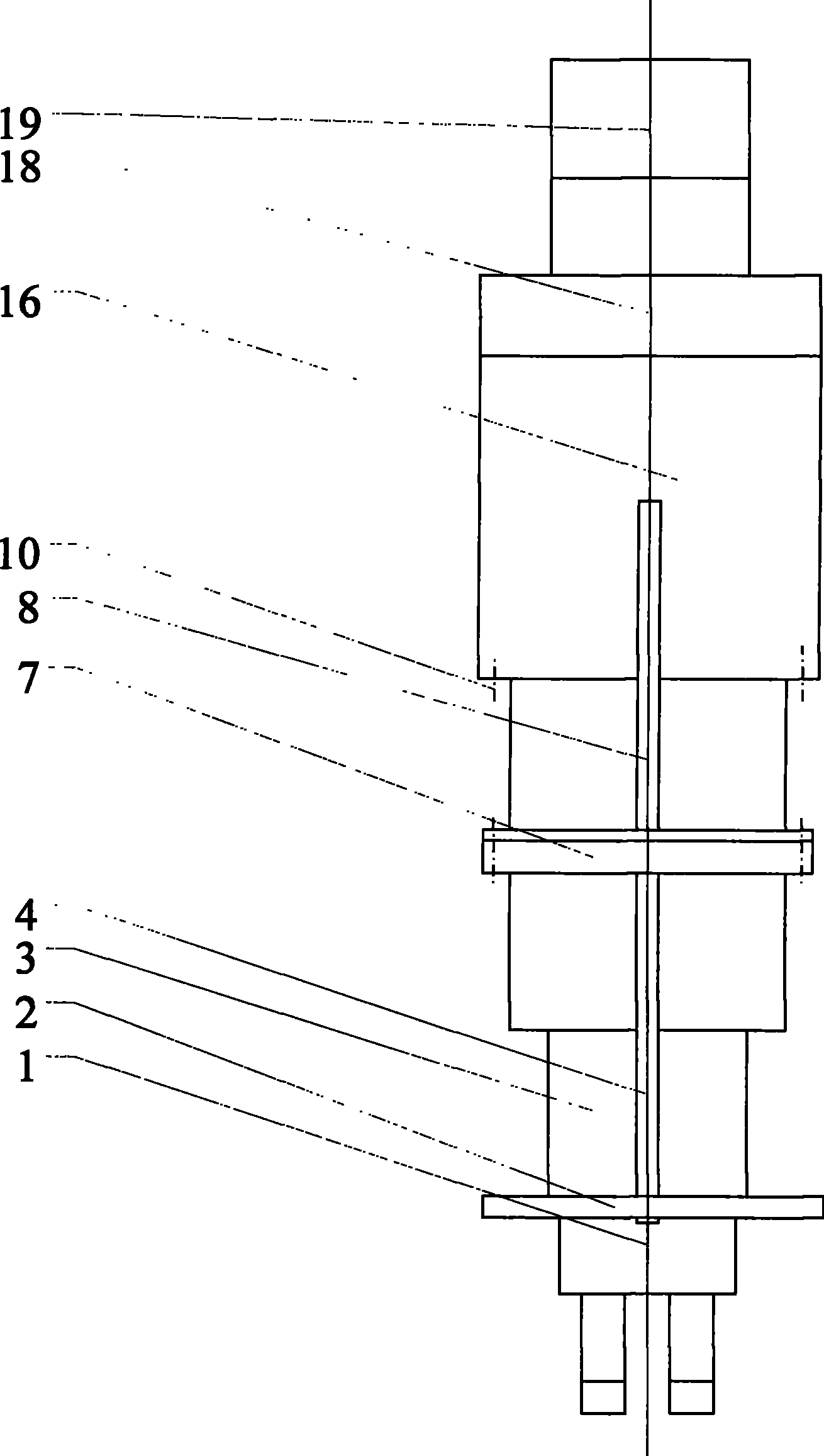

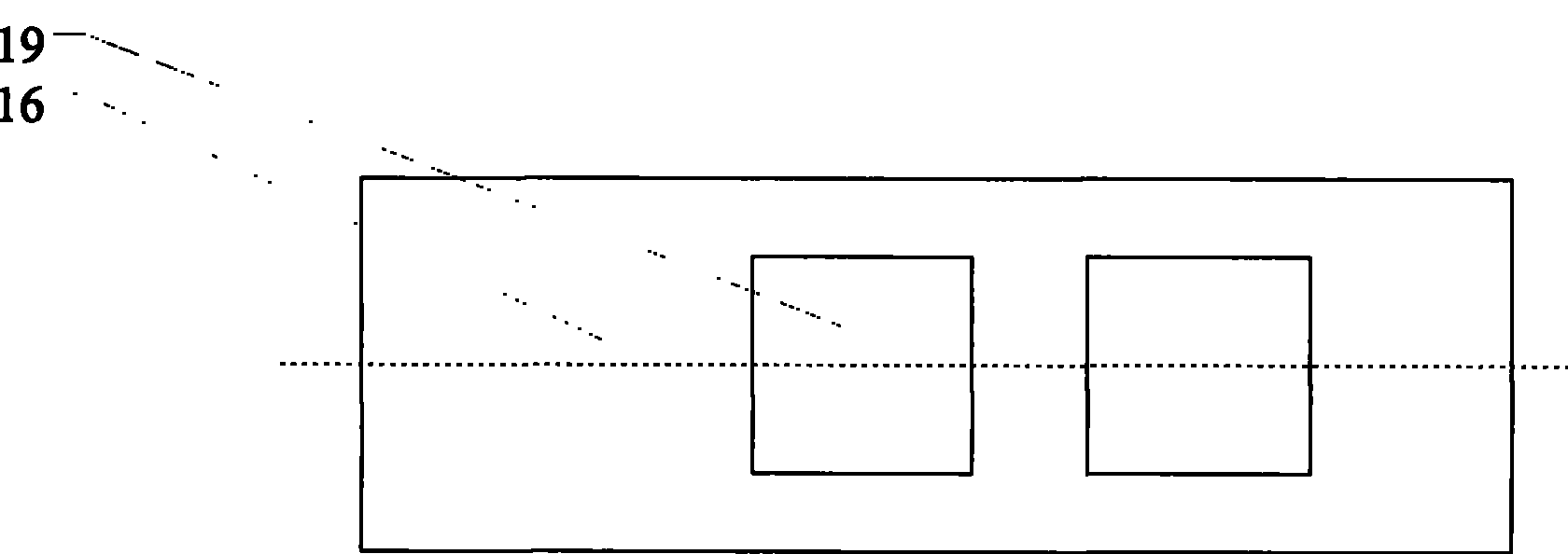

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] see Figure 1 to Figure 4 As shown, the present invention is a digitally controlled flexible frame shape adjustment device, which can realize free shape adjustment in two directions, such as figure 1 As shown, it is composed of a moving bracket 16, a motor 19, a reducer 18, a coupling 17, a screw 11, a screw nut 9, a nut sleeve 3, an ear piece 1, a guide rod sleeve 8, a gear 20, and an angular contact bearing 13 and screw 10 etc. constitute.

[0035] Such as figure 1 As shown, the moving bracket 16 looks like a "T" shape, and has a stepped hole inside, which is used to install the coupling 17, the screw 11 and the angular contact bearing 13 for the positioning of the screw. The moving bracket is the main component of the device. Support parts and core parts.

[0036] Lead screw 11 is fixed: if figure 1 As shown, there is a step in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com