Component quality characteristic integration test equipment and test method

A technology of quality characteristics and testing equipment, which is applied in the testing of machines/structural components, static/dynamic balance testing, weighing, etc. It can solve the problems of accuracy consistency, complex testing process, low efficiency, etc. Safety factor, simple test process, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

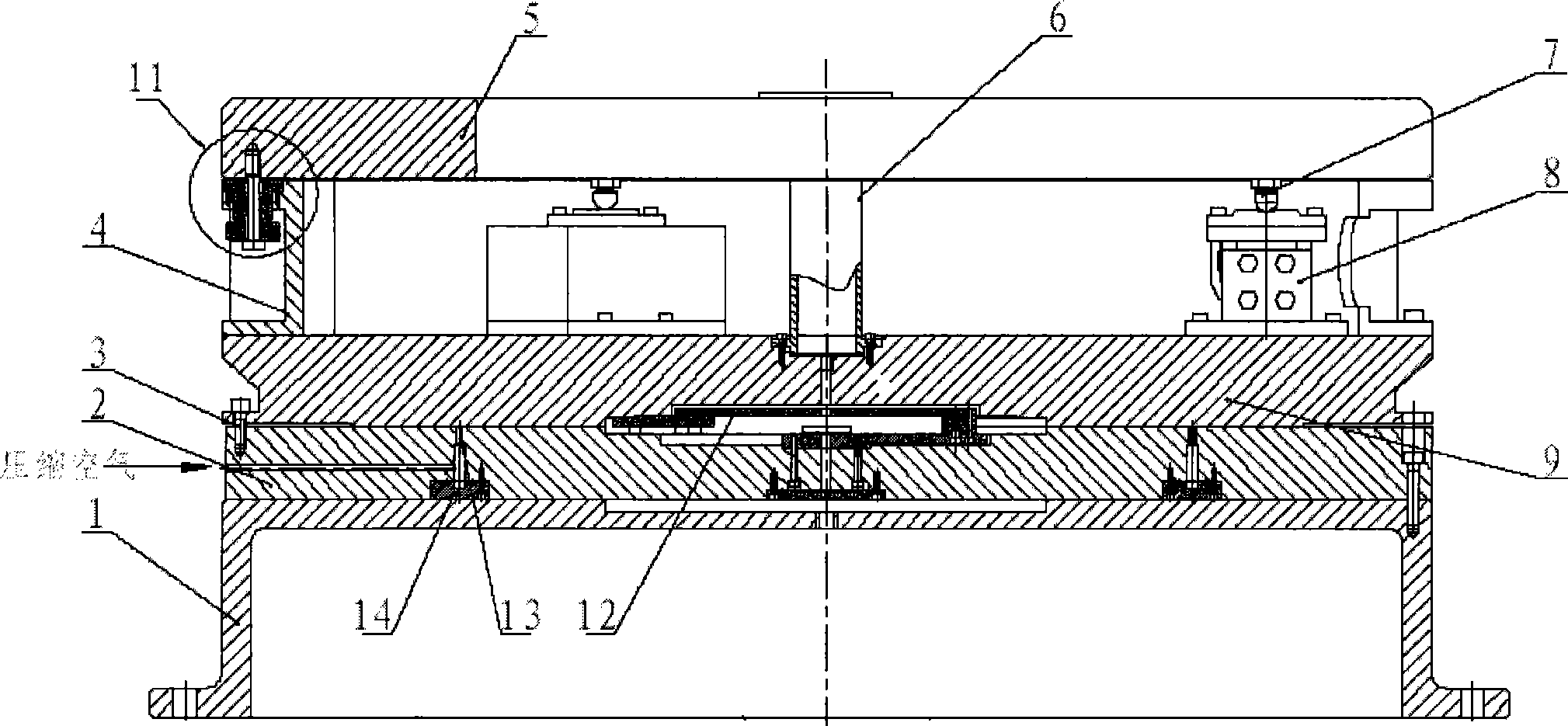

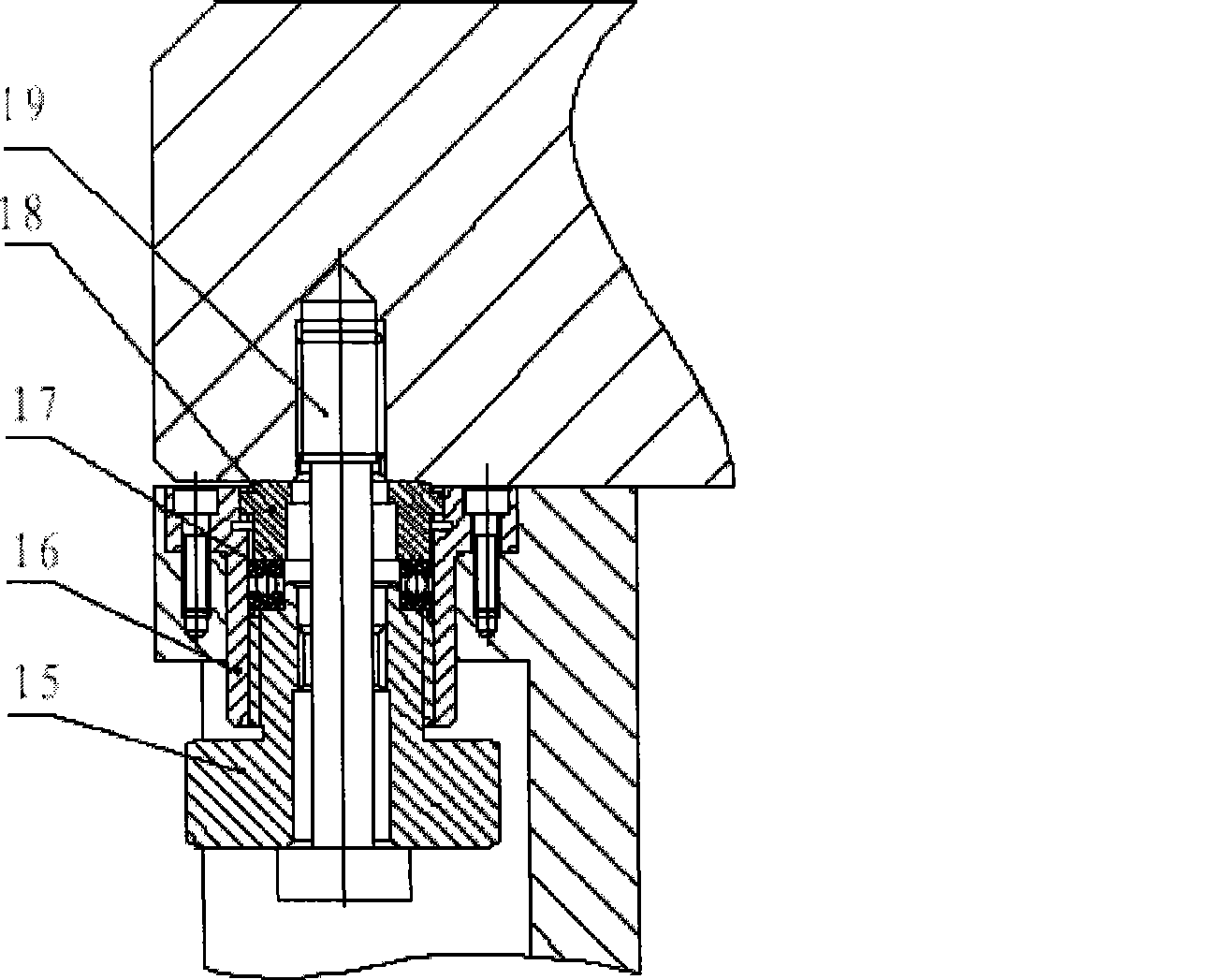

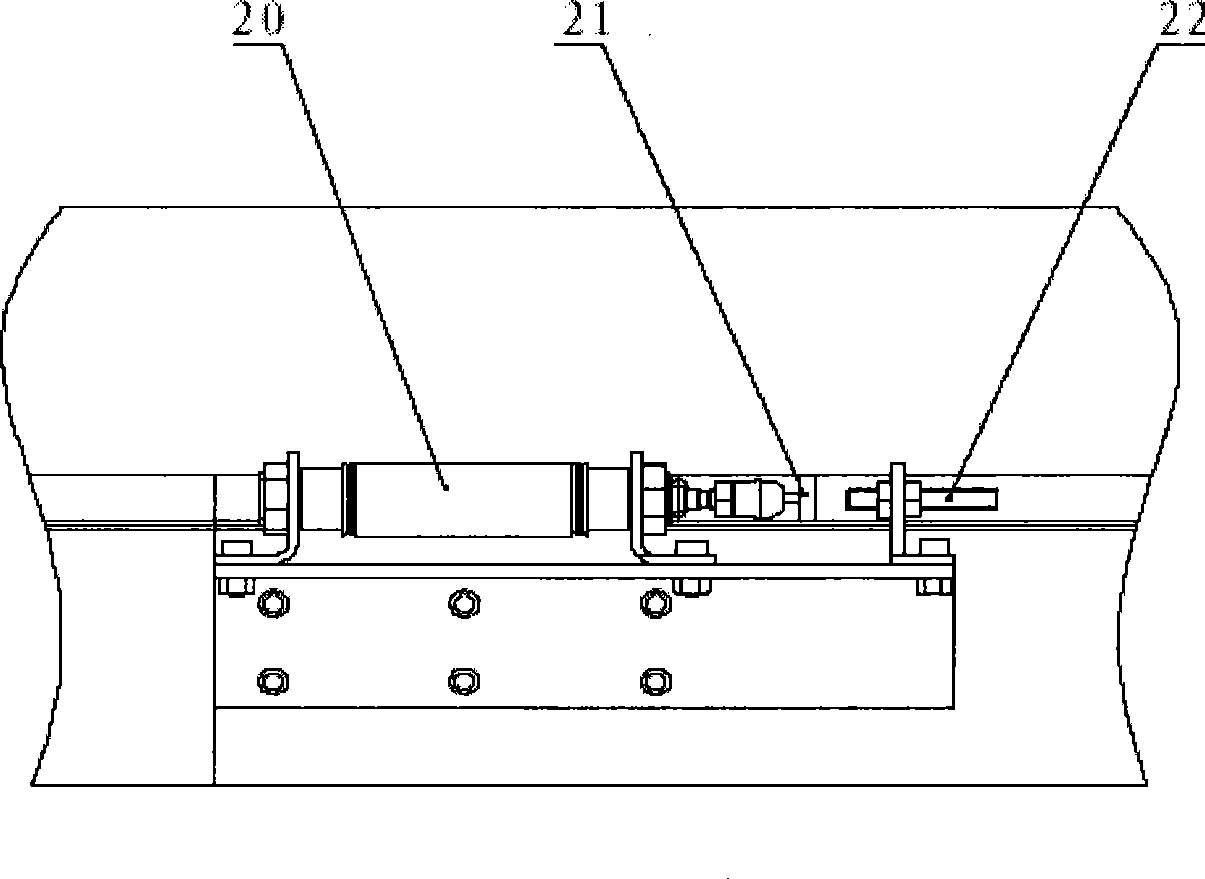

[0028] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes a base 1, the torsion lower plate 2 is fixedly connected to the upper surface of the base 1 by bolts, the bottom of the base 1 is fixed to the foundation by anchor bolts, and before the foundation is fixed, measure the levelness of the base with a spirit level to ensure that the base is stable on the base. The levelness of the surface is within 0.01 / 1m, and then fix the base and anchor bolts. There are air inlet holes on the side of the torsion lower plate 2. After the bolt 3 is removed, the compressed air is introduced into the air channel of the air path sealing plate 14, and the compressed air is sent to the 24 air holes of the torsion upper plate 9 respectively through the air channel, and the torsion lower plate A restrictor 13 with an aperture of 0.25mm is installed in the air hole of the disc, and the compressed air is passed into the air bearing surface between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com