Method for measuring moisten contact angle of powder material

A technology of powder materials and contact angles, applied in the direction of measuring devices, analytical materials, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

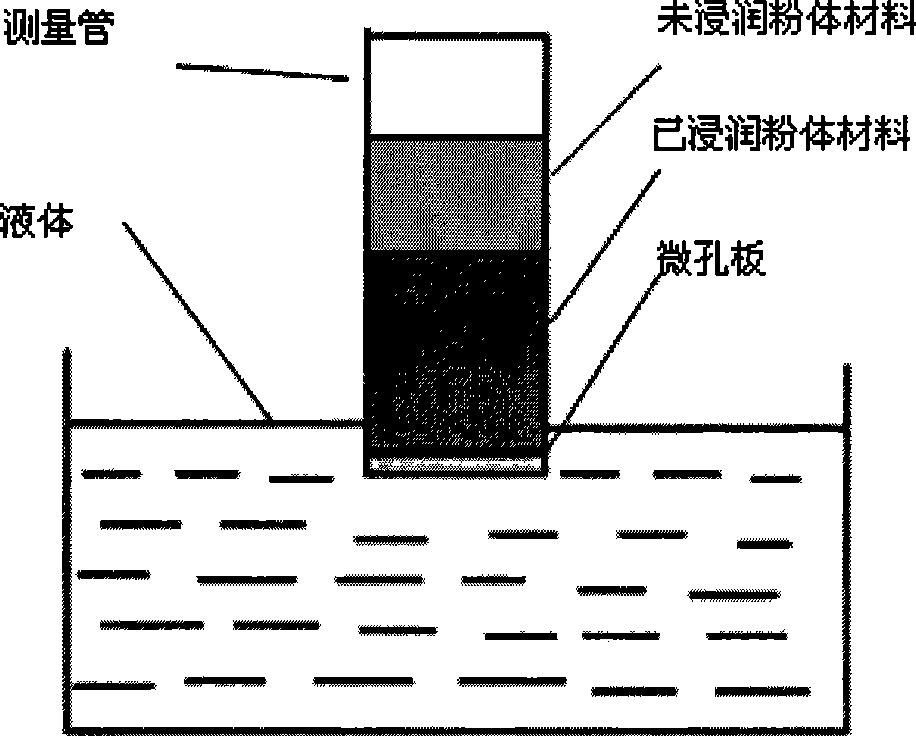

[0030] Weigh a certain amount of a certain powder graphite material, put it into a glass tube whose lower end is sealed with a microporous plate, and press it to a fixed scale to obtain a measuring tube. Use the same method to prepare multiple measuring tubes of the same specification.

[0031] 1) Use water as the wetting liquid, place the measuring tube vertically, and make its lower end contact with water, such as figure 2 shown.

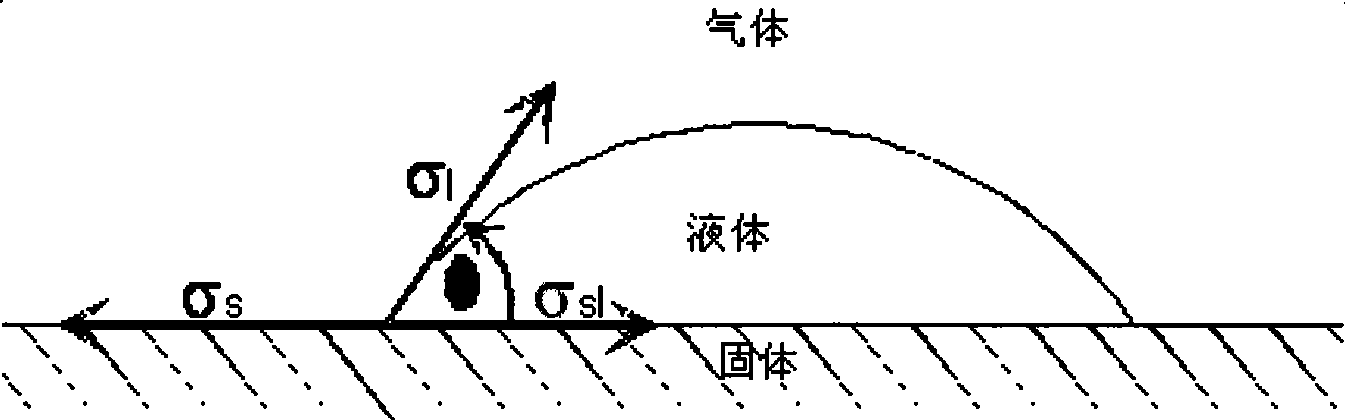

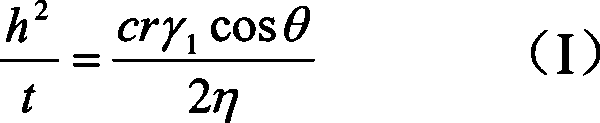

[0032] Considering the pores in the glass tube as a bundle of parallel capillaries with an average diameter r, the following formula can be obtained from the Poiseulle formula (Zhang Futian, Fundamentals of Molecular Interface Chemistry, Shanghai Science and Technology Literature Publishing House, June 2006):

[0033] h 2 t = crγ 1 cos θ 2 η...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com