Method for introducing light shield partial increment magnification coefficient into optical proximity effect model building

A technology of optical proximity effect and amplification factor, which is applied in optics, microlithography exposure equipment, special data processing applications, etc., can solve the problems of wasting modeling and fitting time, poor accuracy, non-convergence, etc., and achieve good physical Significance, effects of speeding up fitting and convergence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

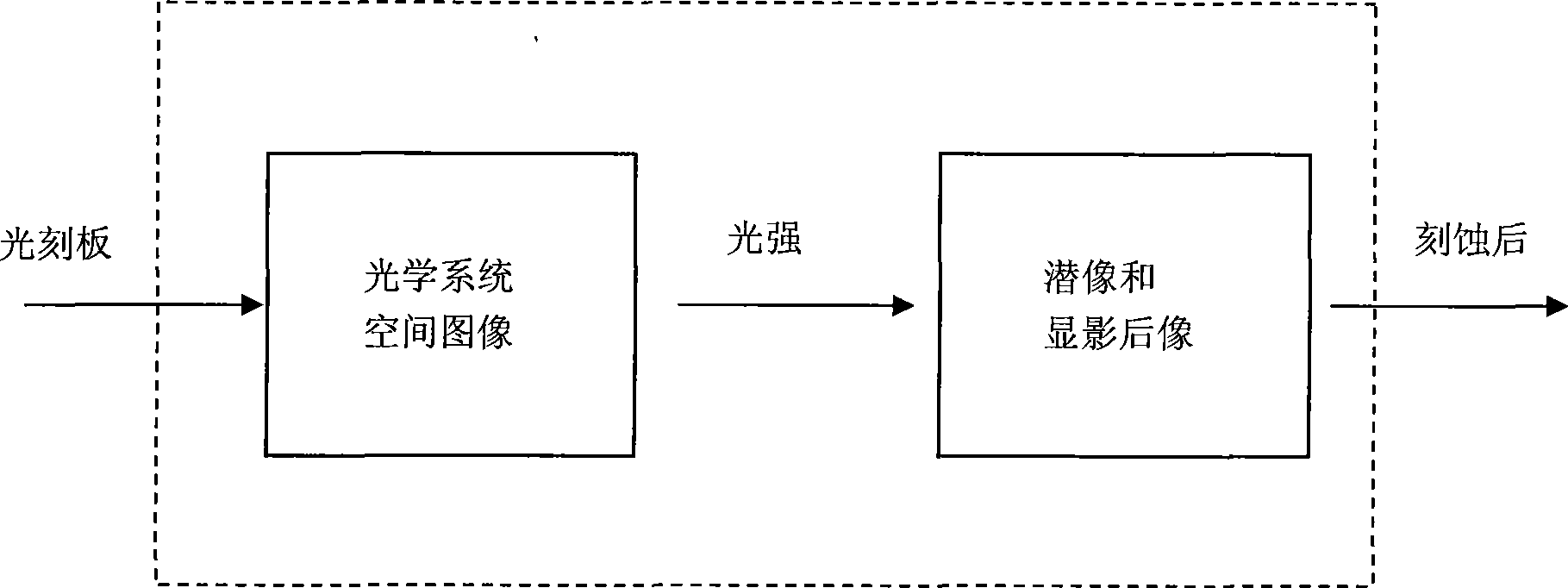

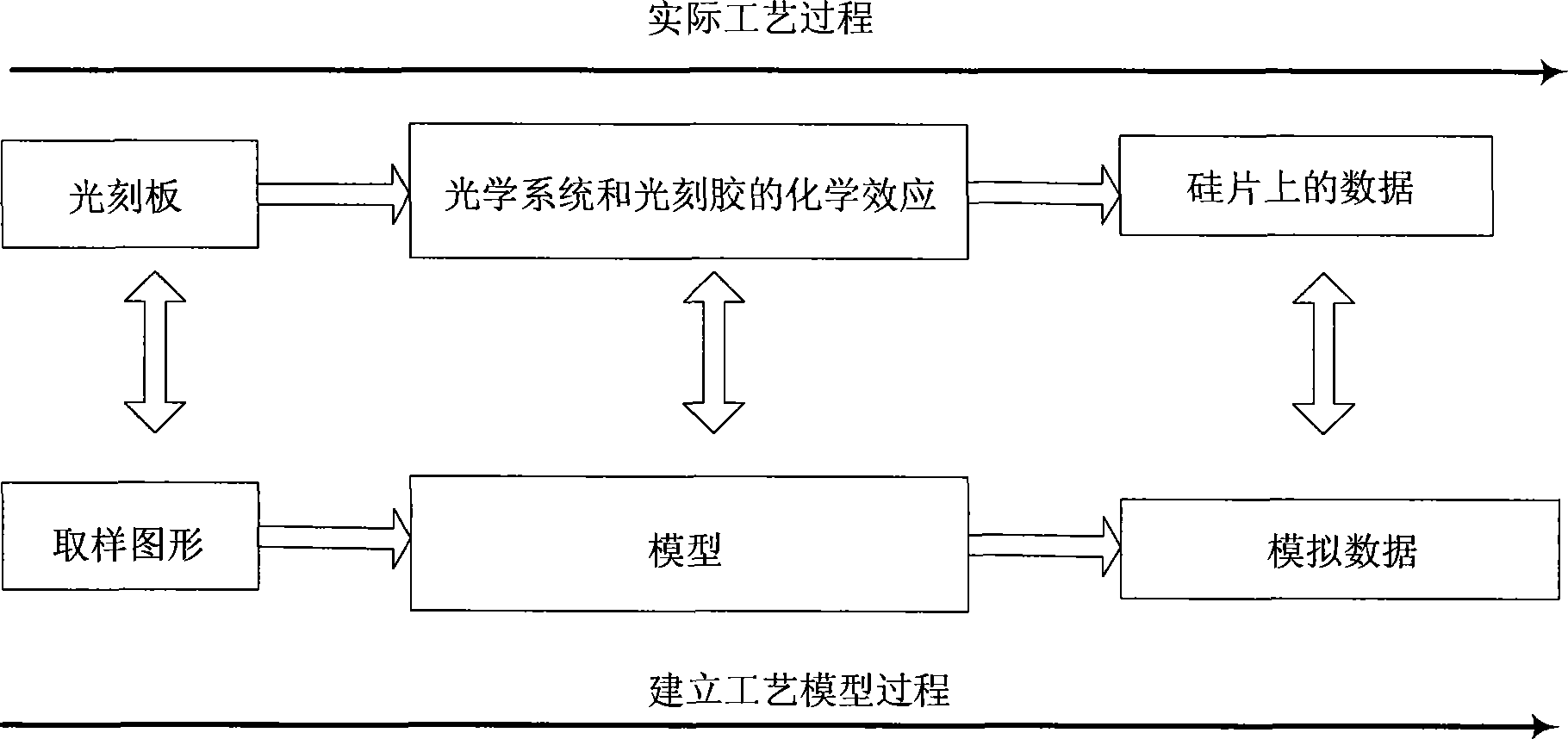

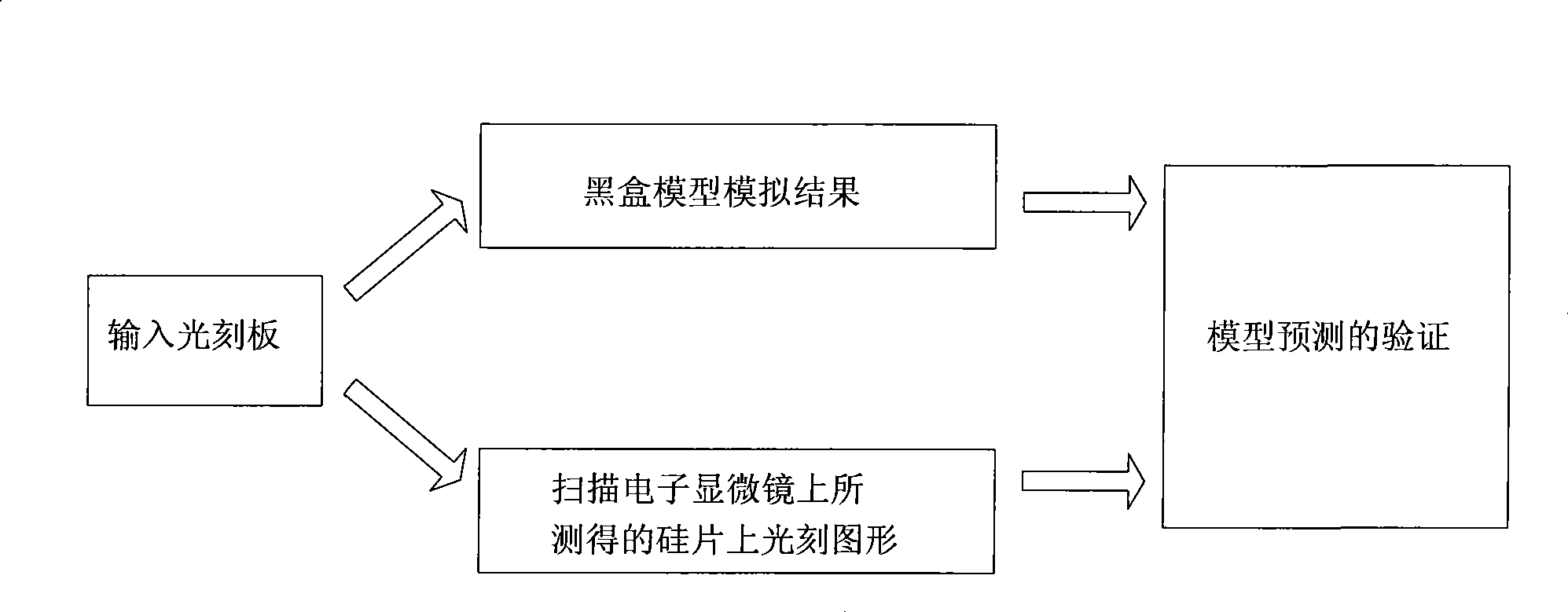

[0022] A reasonable process model should be dominated by the physical model. In the process of establishing the process model, a stable physical optical model must be established first, so that the feature size that may be caused by changes in the optical environment can be well predicted.

[0023] The present invention provides a parameter and method of weight. In the process of collecting the basic process line width data of the process model of the optical proximity effect process, the mask deviation amplification factor MEEF of a specific figure is used.

[0024] Correlate the empirical linewidth data required by the process model with the mask deviation amplification factor MEEF:

[0025] W=W(MEEF)

[0026] In this way, we can filter some unstable factors in the process and measurement, greatly speeding up the fitting and convergence time of the process model establishment, while ensuring the accuracy, reliability and stability of the process model.

[0027] Similarly, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com