Multipath output circuit

A multi-channel output and circuit technology, applied in the direction of electrical components, electronic switches, pulse technology, etc., can solve the problems of high quality and low price, clumsy use, poor contact, etc., and achieve high reliability, light use, and cost-effective improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

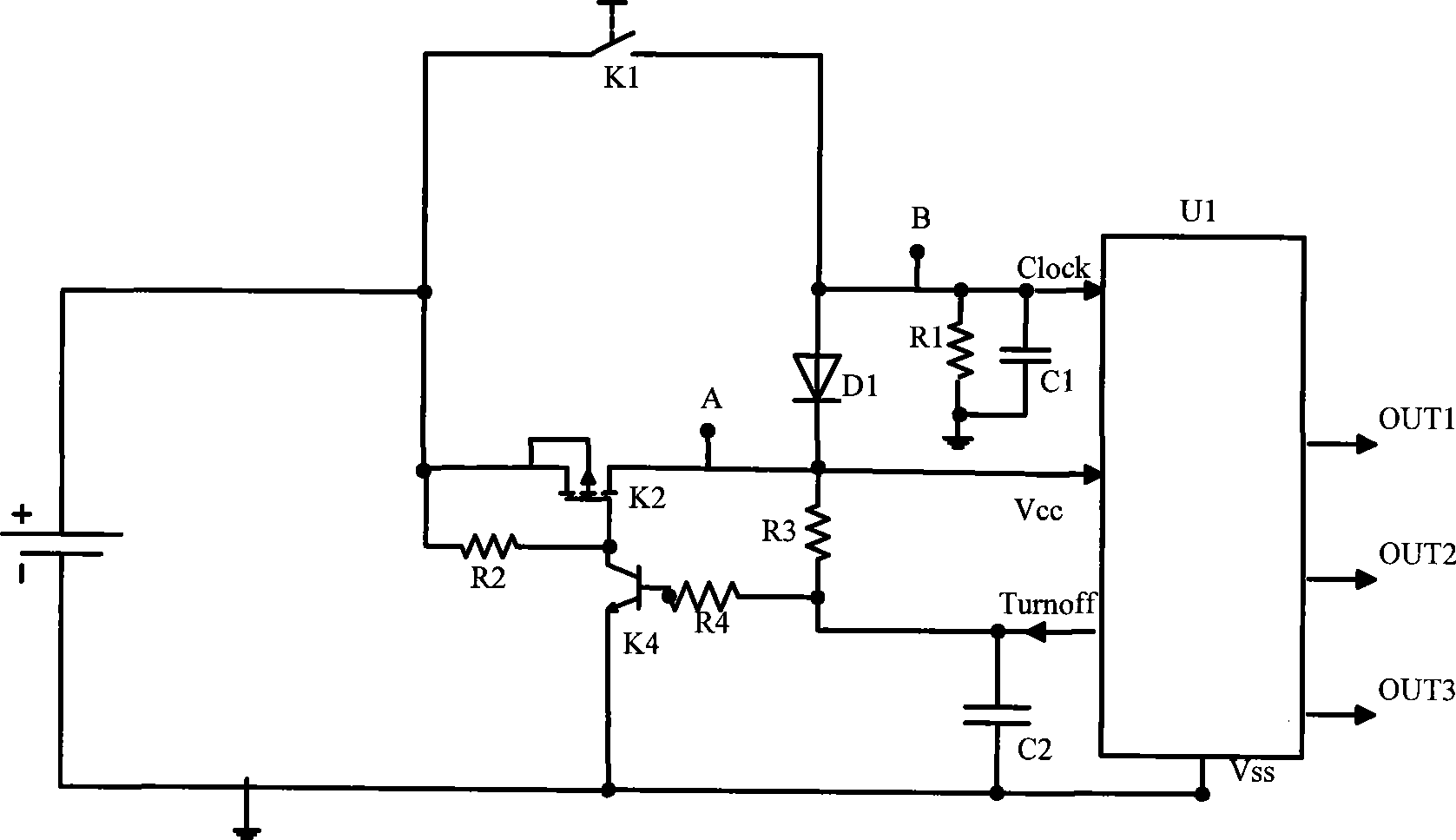

[0020] like figure 1 As shown, a multiplex output circuit includes a first switch K1, a start-up unit, a self-locking unit, a shutdown signal buffer unit and a shift unit U1. The first switch K1 is connected to the starting unit and is connected across the input and output ends of the self-locking unit. The input of the self-locking unit is coupled with the power supply, and the output is coupled with the power supply terminal Vcc of the shifting unit U1, so One end of the shutdown signal buffer unit is coupled to the shutdown signal output end of the shift unit U1, and the other end is coupled to the power supply, and the connection point between the first switch K1 and the start-up unit is coupled to the clock input end of the shift unit U1, so The effective output of the shift unit U1 is shifted backward by one bit every time the clock input terminal of the shift unit U1 receives a pulse. The power source may be a battery.

[0021] like figure 1 As shown, the start-up un...

specific Embodiment approach 2

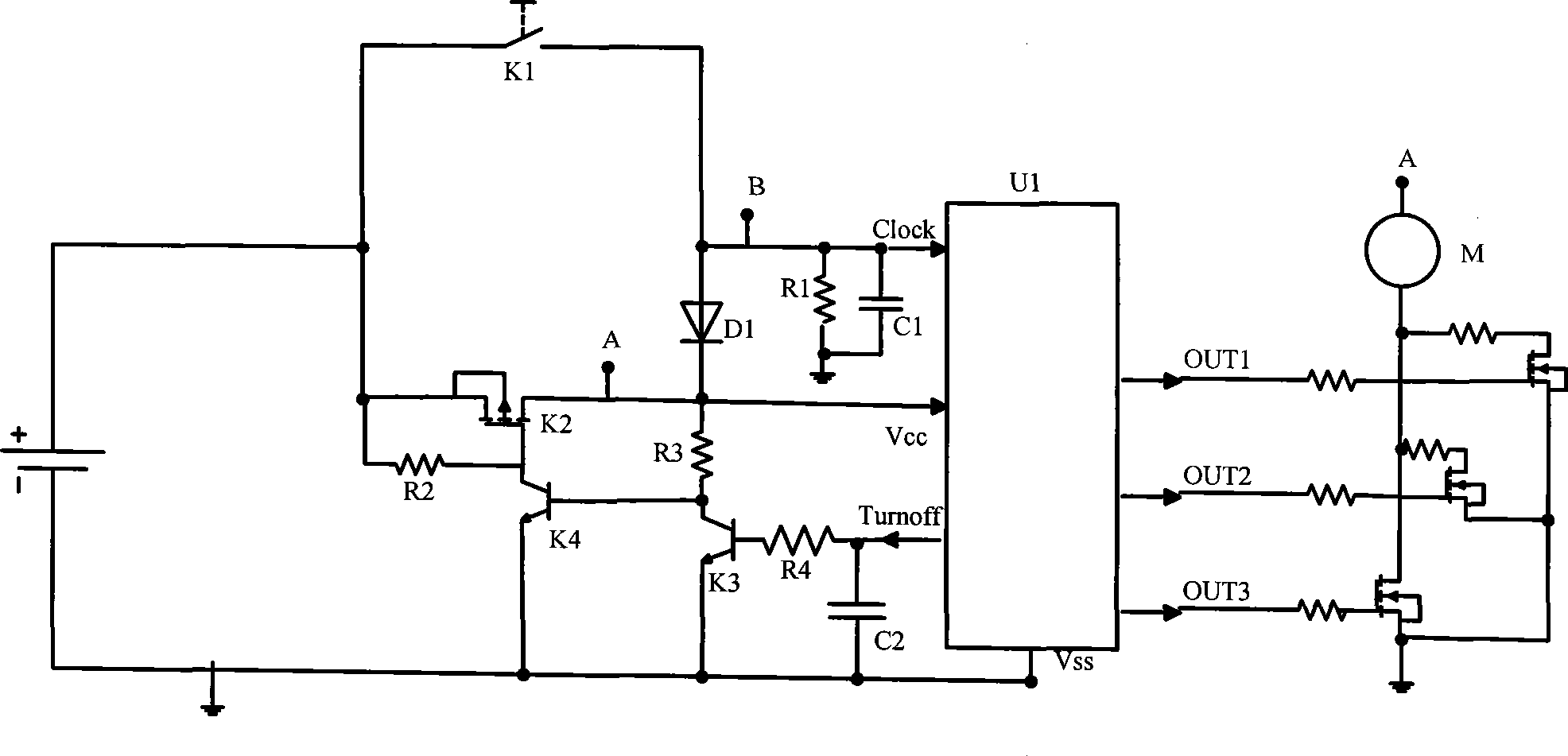

[0031] like figure 2 As shown, the difference between this specific embodiment and the specific embodiment 1 is: in this specific embodiment, the effective output of the shift unit U1 is a high level, this specific embodiment needs to add a reverse unit, the reverse The unit is coupled between the control terminal of the self-locking unit and the shutdown signal output terminal of the shift unit U1. Moreover, the circuit structure of the self-locking unit of this specific embodiment is slightly different from that of the self-locking unit of the first embodiment. This will be further explained below.

[0032] like figure 2 As shown, the startup unit includes a first diode D1, and the self-locking unit includes a second switch tube K2, a third resistor R3, a second resistor R2, and a fourth switch tube K4.

[0033] like figure 2 As shown, the anode of the first diode D1 is connected to the first switch K1, the cathode is connected to the second end of the second switch t...

specific Embodiment approach 3

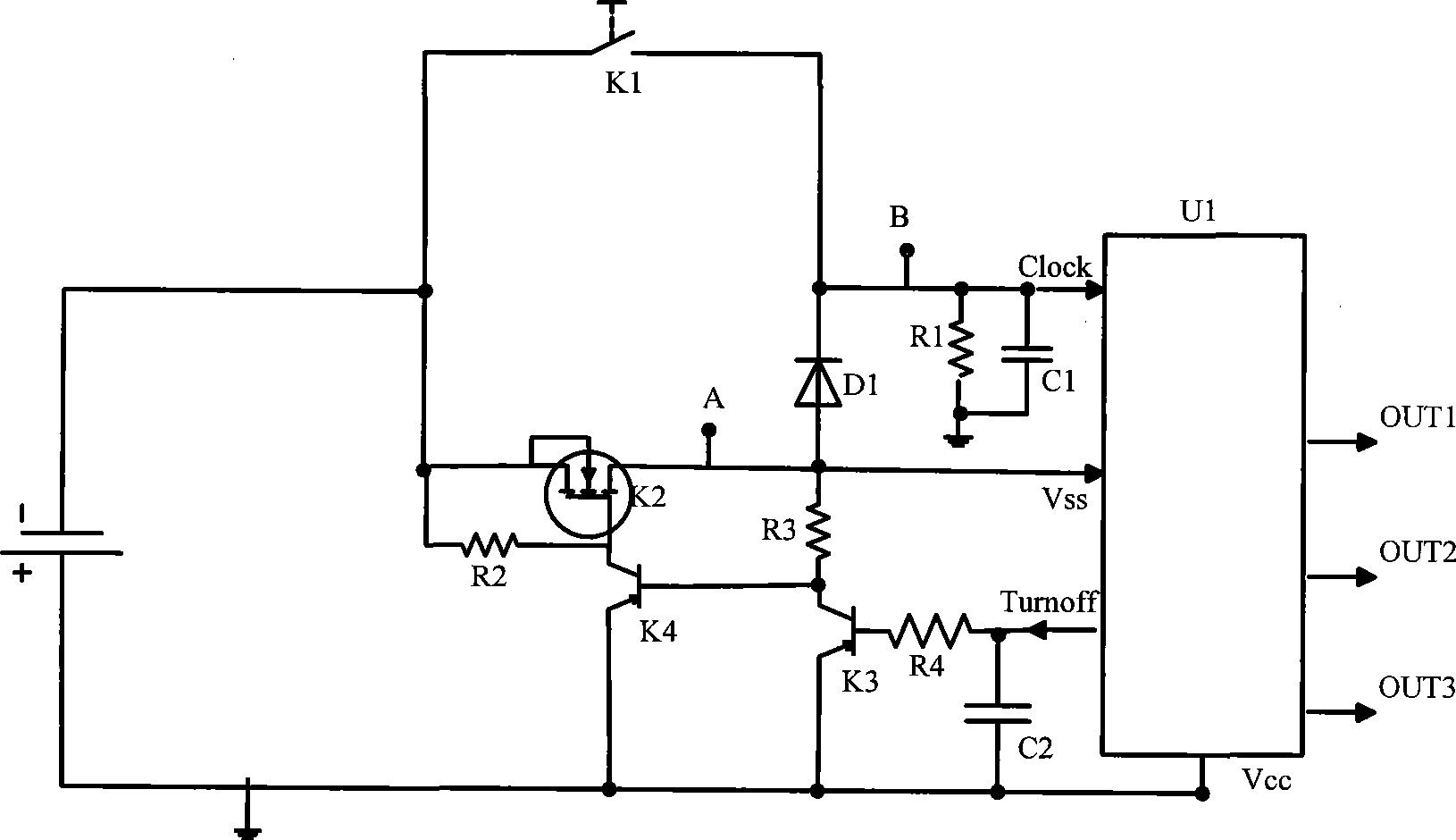

[0041] like image 3 As shown, the difference between this specific embodiment and the first specific embodiment is that: in this specific embodiment, the circuit structure is of negative logic, and the positive electrode of the power supply is grounded. The circuit structure of this specific implementation is slightly different from the circuit structure of the specific implementation manner, and the details are as follows:

[0042] like image 3 As shown, the startup unit includes a first diode D1, and the self-locking unit includes a second switch tube K2, a third resistor R3, a second resistor R2, a fourth resistor R4, and a fourth switch tube K4; the The cathode of the first diode D1 is connected to the first switch K1, the anode is connected to the second end of the second switch tube K2, the first end of the second switch tube K2 is connected to the negative pole of the power supply, and the second switch tube K2 is the second The terminal is also connected to the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com