Moisture proof and warming electric heating board and preparation thereof

An electric heating plate and benzene plate technology, applied in electric heating devices, ohmic resistance heating, chemical instruments and methods, etc., can solve the problems of super insulation and super heat dissipation of carbon material electric heating plates, hinder the development of electric heating technology, and use safety hazards. and other problems, to achieve the effect of sufficient raw material sources, wide application range, and avoidance of leakage problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

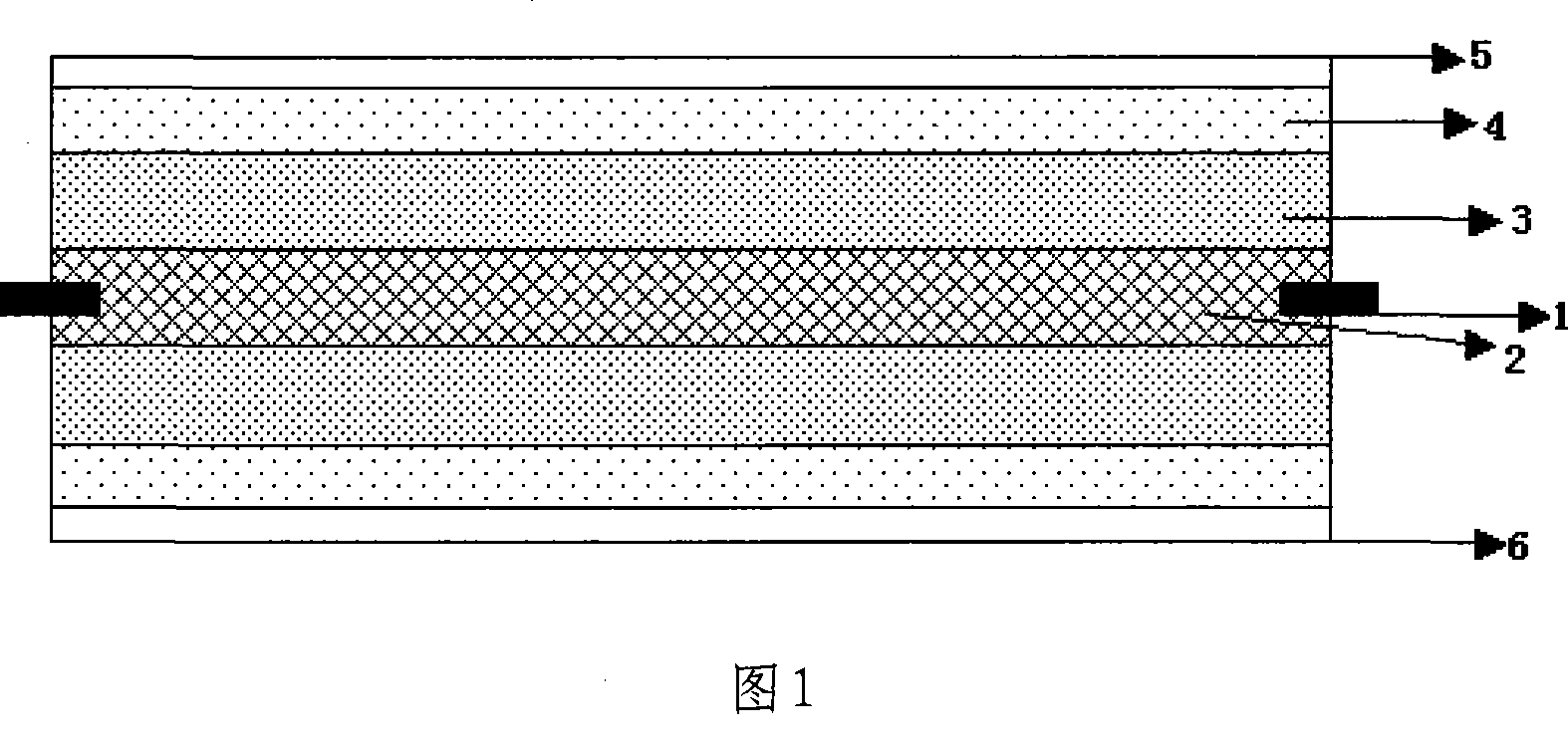

[0024] The moisture-proof heating electric heating plate includes a heating element 2 and a waterproof and heat-conducting layer 4, and the waterproof and heat-conducting layer 4 covers the heating element; it also includes a glass fiber layer 3, which is arranged between the heating element 2 and the waterproof and heat-conducting layer 4; the waterproof and heat-conducting layer 4—The outer surface is laid with an insulating layer 6; the heating element 2 is a structure with electrodes 1 arranged at both ends of the conductive paper.

[0025] Production method: ① Mix 70% pulp by weight, 20% carbon material (carbon fiber, nano-carbon fiber or pulp), and 10% epoxy resin to make conductive paper by papermaking, and inlay electrodes on the symmetrical side 1 Make a heating element 2 with a heating temperature of 30°C. ② Mix 100 parts by weight of polyester resin, 50 parts of powdered silicon dioxide or silica powder (200 mesh), 4 parts of curing agent, 2 parts of accelerator or ...

Embodiment 2

[0028] The difference between the moisture-proof heating electric heating plate and the embodiment 1 is that: the other outer surface of the waterproof and heat-conducting layer 4 is covered with a decorative layer 5 .

[0029] Production method: ① Mix 80% pulp by weight, 15% carbon material (carbon fiber, nano-carbon fiber or pulp), and 5% epoxy resin to make conductive paper by papermaking, and inlay electrodes on the symmetrical side 1 Make a heating element 2 with a heating temperature of 40°C. ② Mix 150 parts by weight of epoxy resin, 80 parts of powdered silicon dioxide or silica powder (800 mesh), 50 parts of curing agent, 4 parts of accelerator or 20 parts of thinner to evenly prepare the mixture, Soak the mixture with 0.4mm thick glass fiber cloth and wrap it on both sides of the heating element 2 to make the glass fiber layer 3. 2 Made into slabs under high pressure. ③Then mix 100 parts by weight of resin, 250 parts of silica powder or silica powder (200 mesh), 50 ...

Embodiment 3

[0031] Production method: ① Mix 88% pulp by weight, 10% carbon material (carbon fiber, nano-carbon fiber or pulp), and 2% epoxy resin to make conductive paper by papermaking, and inlay electrodes on the symmetrical side 1 Make a heating element 2 with a heating temperature of 50°C. 2. 200 parts by weight of polyester resin, 65 parts of powdered silicon dioxide or silica powder (1500 mesh), 100 parts of curing agent, 5 parts of accelerator or 30 parts of diluent are mixed uniformly to prepare the mixture, Use 0.4mm thick glass fiber cloth to impregnate the mixture and wrap it on both sides of the heating element 2 to form a glass fiber layer 3. Heat the heating element 2 covered with the glass fiber layer 3 at a high temperature of 150°C and 50kgf / cm 2 Made into slabs under high pressure. ③Then mix 200 parts by weight of resin, 300 parts of silica powder or silica powder (300 mesh), 100 parts of curing agent, 5 parts of accelerator or 30 parts of diluent to make waterproofing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com