Automatic powder loading machine and method for optical fiber ceramic sleeve barrel

A technology for ceramic sleeves and optical fibers, which is applied in ceramic molding machines, supply devices, manufacturing tools, etc., can solve the problems of troublesome powder loading operation and low efficiency, and achieve the effect of stable product quality, high efficiency and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

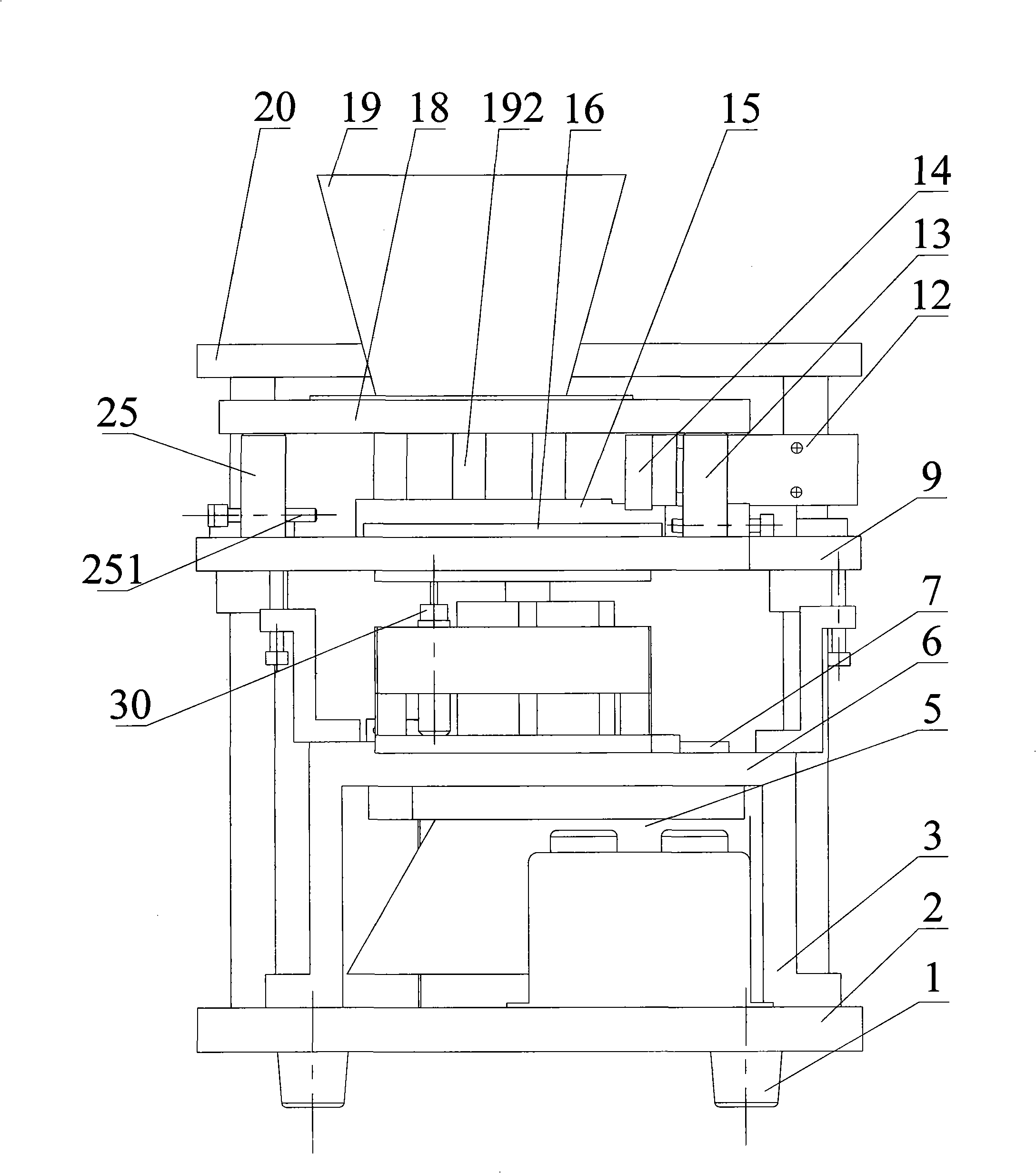

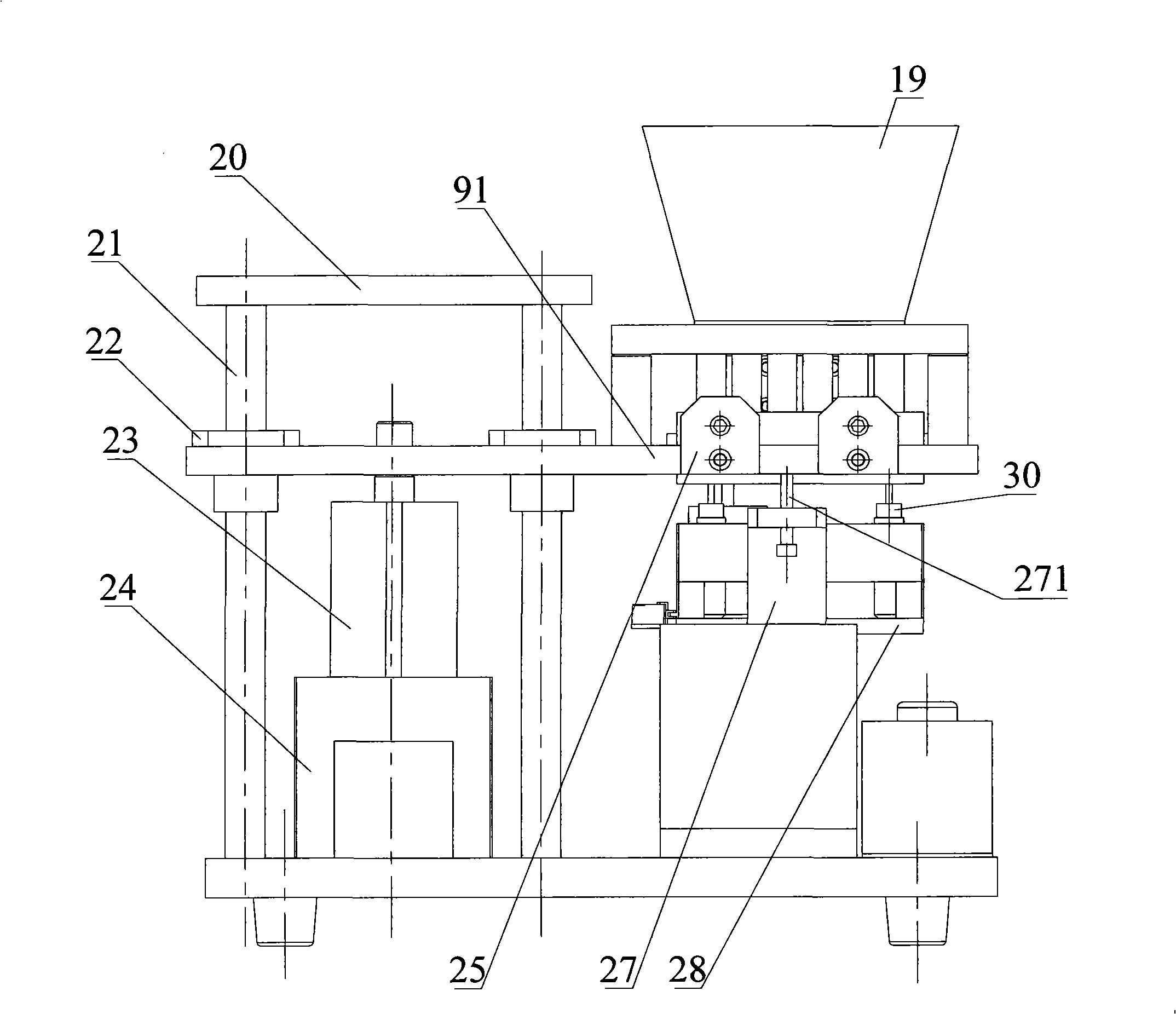

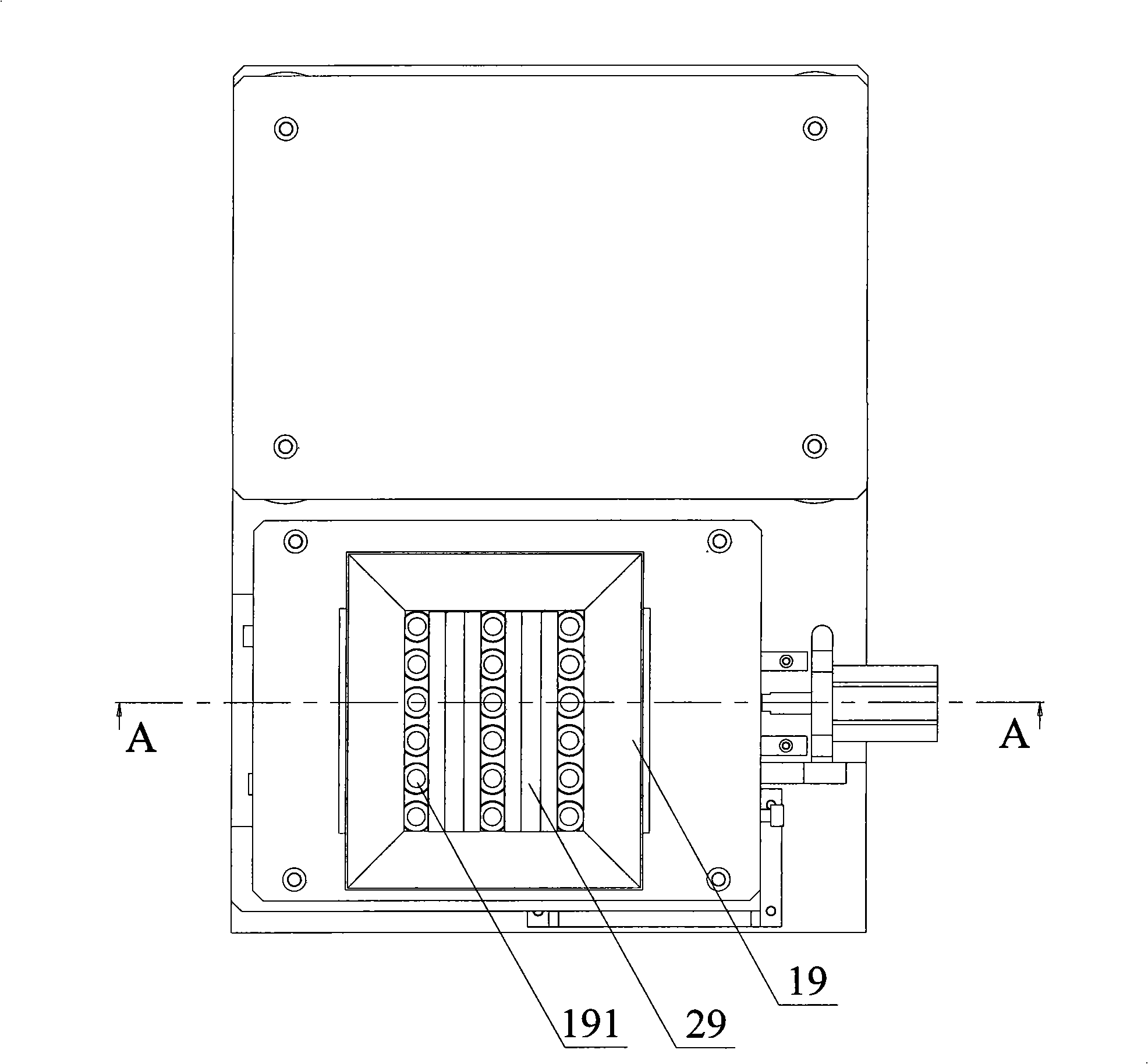

[0031] Such as Figure 1 to Figure 5 As shown, in one embodiment of the fiber optic ceramic sleeve automatic powder loading machine of the present invention, it includes a powder box 19, a volumetric block 15, a driving mechanism, a powder drain plate, a filling fixture assembly 28, a vibrator 5, and the like. In this embodiment, in order to facilitate the installation of the filling fixture assembly 28 , the automatic powder filling machine also includes a lifting mechanism, which can drive the powder leaking plate to move up and down to install the filling fixture assembly 28 . The above-mentioned parts can be installed on the same workbench 2 to facilitate installation and transportation; of course, they can also be installed separately in different positions. The automatic powder filling machine is also provided with a working switch for controlling the opening of the automatic powder filling machine. A rubber foot pad 1 can also be installed on the bottom of the workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com