Dual-adjacent high-sound insulation combined cabin

A cabin and high-isolation technology, applied in the field of ship cabins, can solve the problems of high sound insulation and achieve good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 is a kind of two adjacent combined cabins, it is made of non-common wall panels, public wall panels, ceilings, cabin fire doors, sanitary units and profiles for fixing and connecting wall panels, ceilings, cabin fire doors, and sanitary units Assembled.

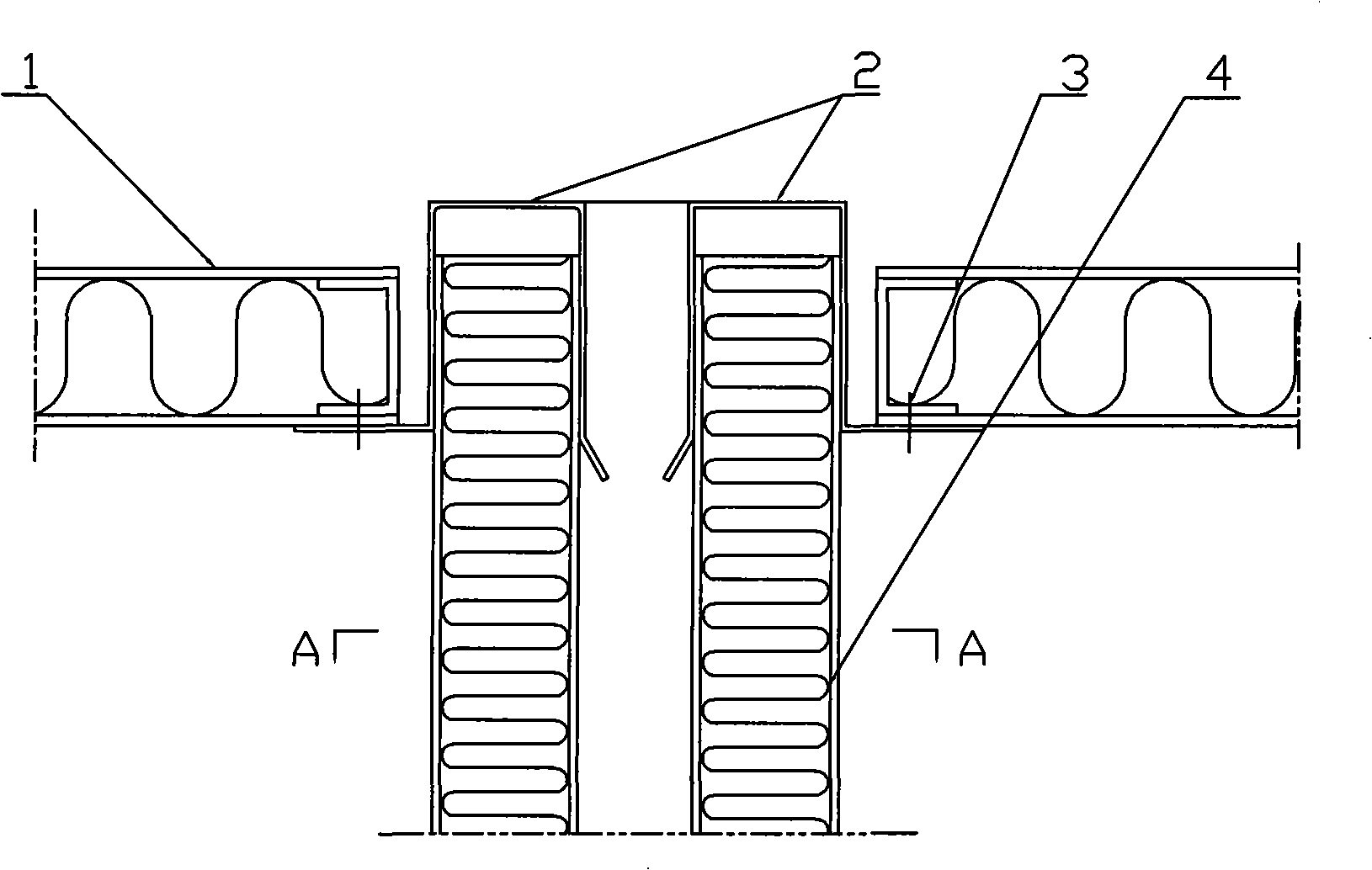

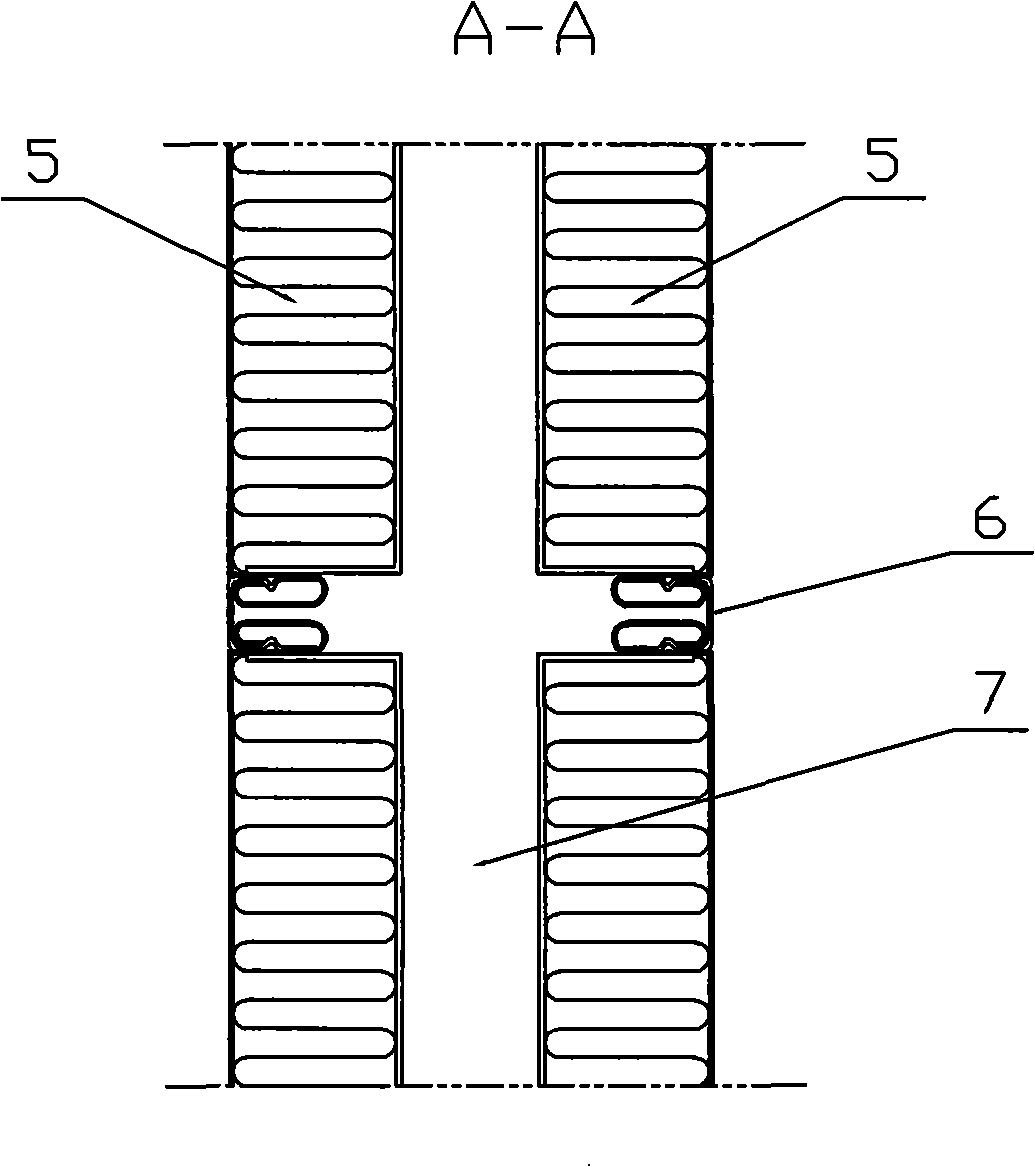

[0030] see figure 1 , figure 2 , the common wall plate 4 is the common wall plate of two adjacent cabins, and it is made up of two layers of wall plates 5 and an interlayer 7 in the middle, and each layer of wall plates 5 is composed of a single layer of 25mm or 30mm thick metal composite rock wool board. The interlayer 7 is an air layer without filling material, the gap between the interlayer 7 is 20-100mm, and the total thickness of the common wallboard 4 is 70-160mm. The non-public wall board is composed of a single layer of 25mm or 30mm thick metal composite rock wool board. The non-public wall board 27 connected to the public wall board 4 is provided with a U-shaped wrapping 28 at its connecting en...

Embodiment 2

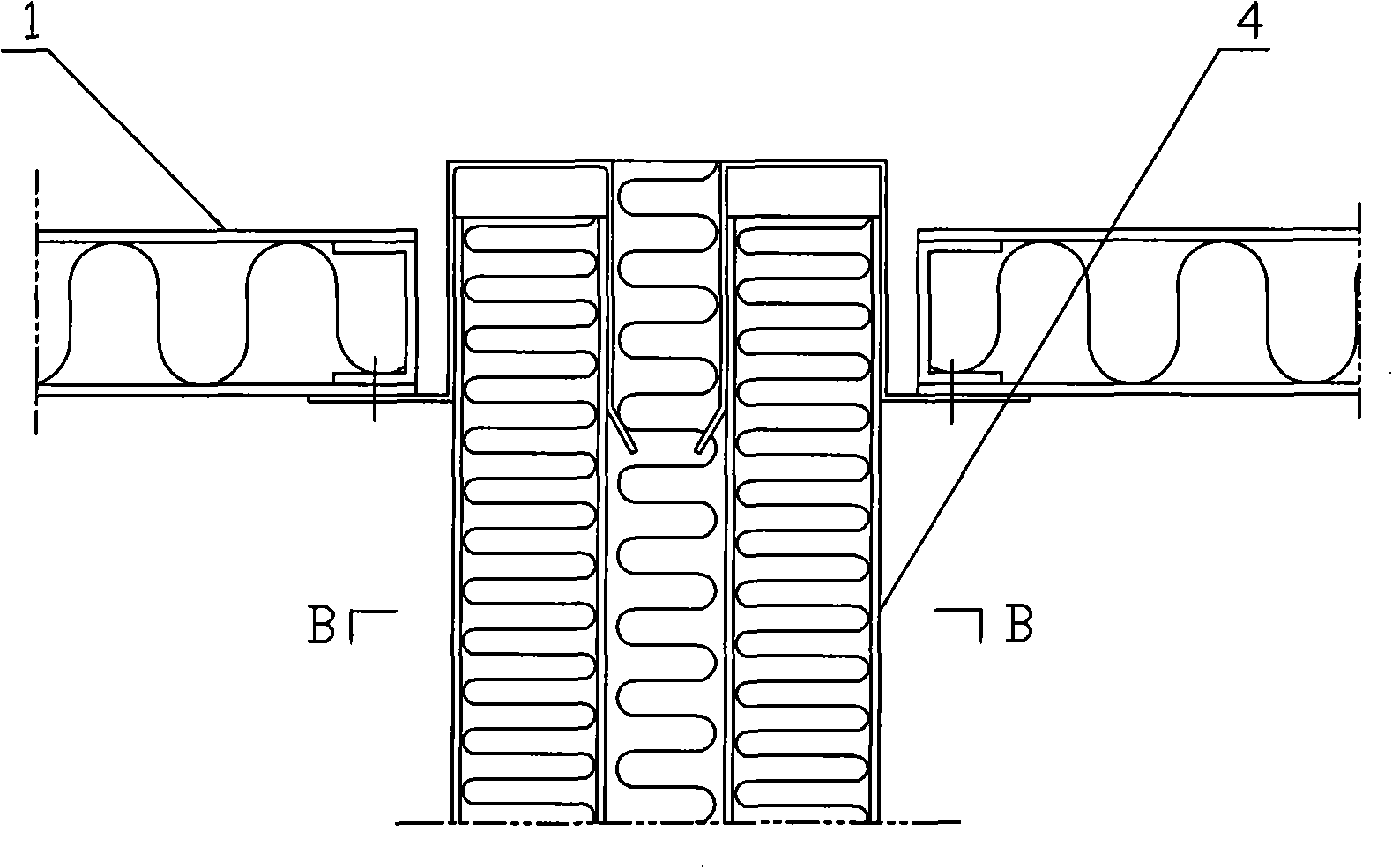

[0043] Embodiment two is two adjacent high sound insulation combined cabins, see image 3 with Figure 4 , the common wall board 4 is composed of two layers of 25mm or 30mm thick C-shaped metal composite rock wool board 5 and an interlayer 7, the interlayer 7 is filled with a thickness of 20-50mm and a density of 80-100kg / m 3 The outer panel of the metal composite rock wool board is 0.6mm thick PVC-coated steel plate, color-coated steel plate or spray-coated steel plate, and the inner panel is 0.6mm-thick galvanized steel plate, PVC-coated steel plate, color-coated steel plate or spray-coated Steel plate, the middle filling density is 150kg / m 3 rock wool. The non-public wall panel is composed of a single layer of 25mm or 30mm thick C-shaped metal composite rock wool board. Steel plate, PVC laminated steel plate, color-coated steel plate or spray-coated steel plate, the filling density in the middle is 150kg / m 3 rock wool.

[0044] The ceiling 1 of embodiment 2 adopts one ...

Embodiment 3

[0047] Embodiment 3 is two adjacent high-sound-insulation combined cabins. The common wall panels are composed of two layers of 25mm or 30mm thick A-type metal composite rock wool boards and interlayers. The interlayers are filled with a thickness of 20-50mm and a density of 100- 150kg / m 3 The outer panel of the metal composite rock wool board is 0.7mm thick PVC-coated steel plate, color-coated steel plate or spray-coated steel plate, and the inner panel is 0.7mm-thick galvanized steel plate, PVC-coated steel plate, color-coated steel plate or spray-coated Steel plate, the middle filling density is 150kg / m 3 rock wool. The non-public wall panel is composed of a single layer of 25mm or 30mm thick metal composite rock wool board, the outer panel is 0.6mm thick PVC laminated steel plate, color coated steel plate or sprayed steel plate, and the inner panel is 0.6mm thick galvanized steel plate, PVC Plastic-coated steel plate, color-coated steel plate or spray-coated steel plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com