Nondestructive demounting method for prefabricated part of IMS system Dai nationality folk house major structure

A technology of main structure and prefabricated components, applied in building construction, building maintenance, construction, etc., can solve the problems of prefabricated components being damaged and unable to be reused, and achieve the effect of reducing solid waste, reducing resource waste, and protecting the ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

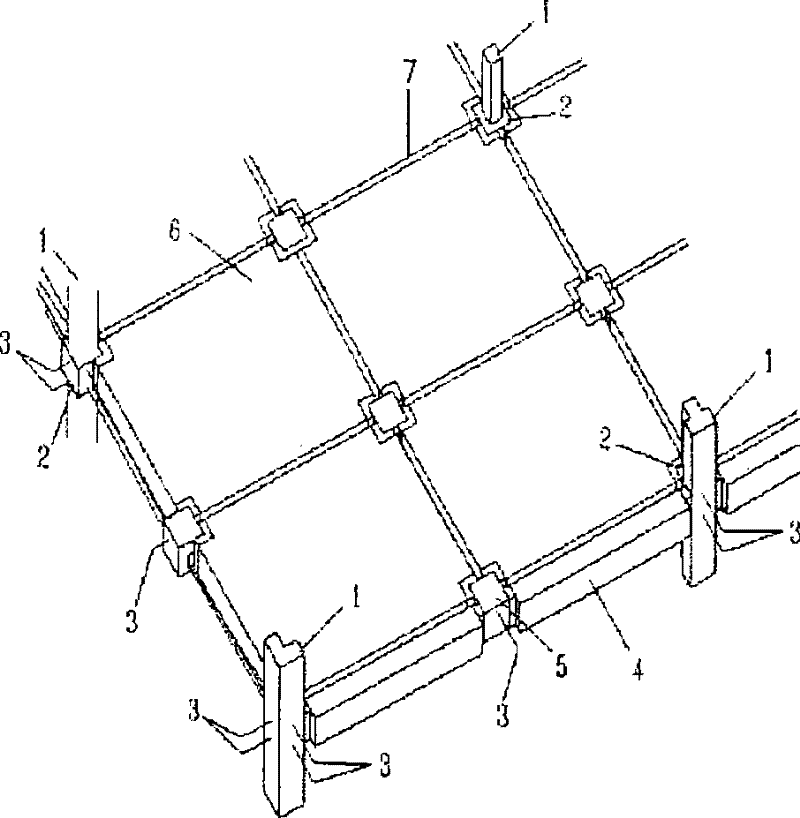

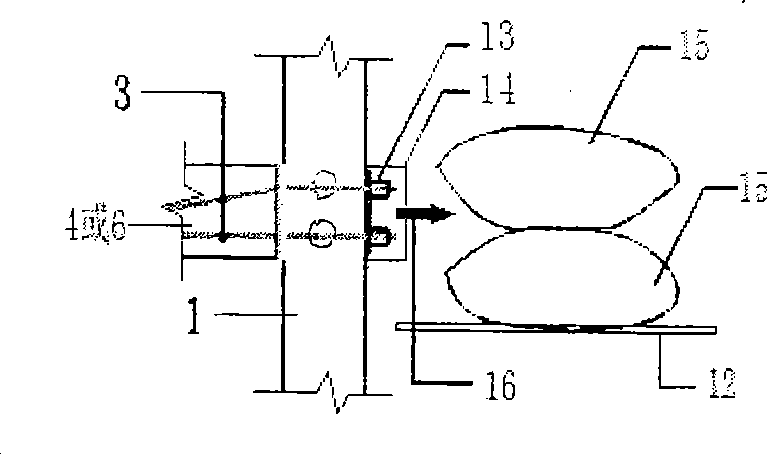

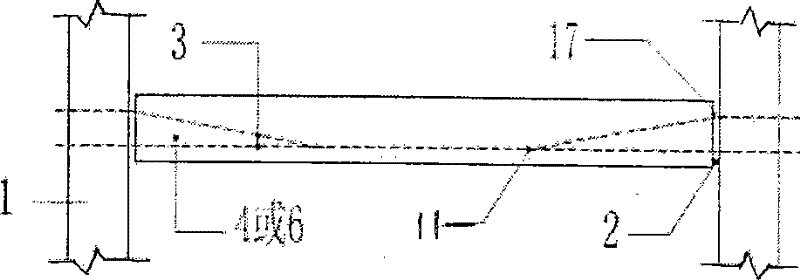

[0023] Such as figure 1 As shown, the construction method of the main structure of the Dai folk houses in the IMS system is as follows: hoist all prefabricated components in place, reserve 25 mm wide joints between prefabricated columns 1, prefabricated beams 4, and prefabricated slabs 5, and prefabricated pads 5 and prefabricated beams 4. Reserve 25 mm wide joints between the prefabricated panels 5, fill the above joints with high-strength caulking mortar 2, and maintain the caulking mortar 2 to the design strength. Pass the prestressed steel strand 3 through the holes and open slots reserved in the prefabricated components and stretch them, then pour concrete into the open slots to form the open slots and then pour concrete 7 . The post-casting concrete 7 of the open channel wraps the prestressed steel strand 3 to form bonded prestress. At this time, a prestressed friction joint is formed between the prefabricated slab 6, the prefabricated beam 4 and the prefabricated colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com