Engine with variable compression ratio

A compression ratio, engine technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve uncontrollable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

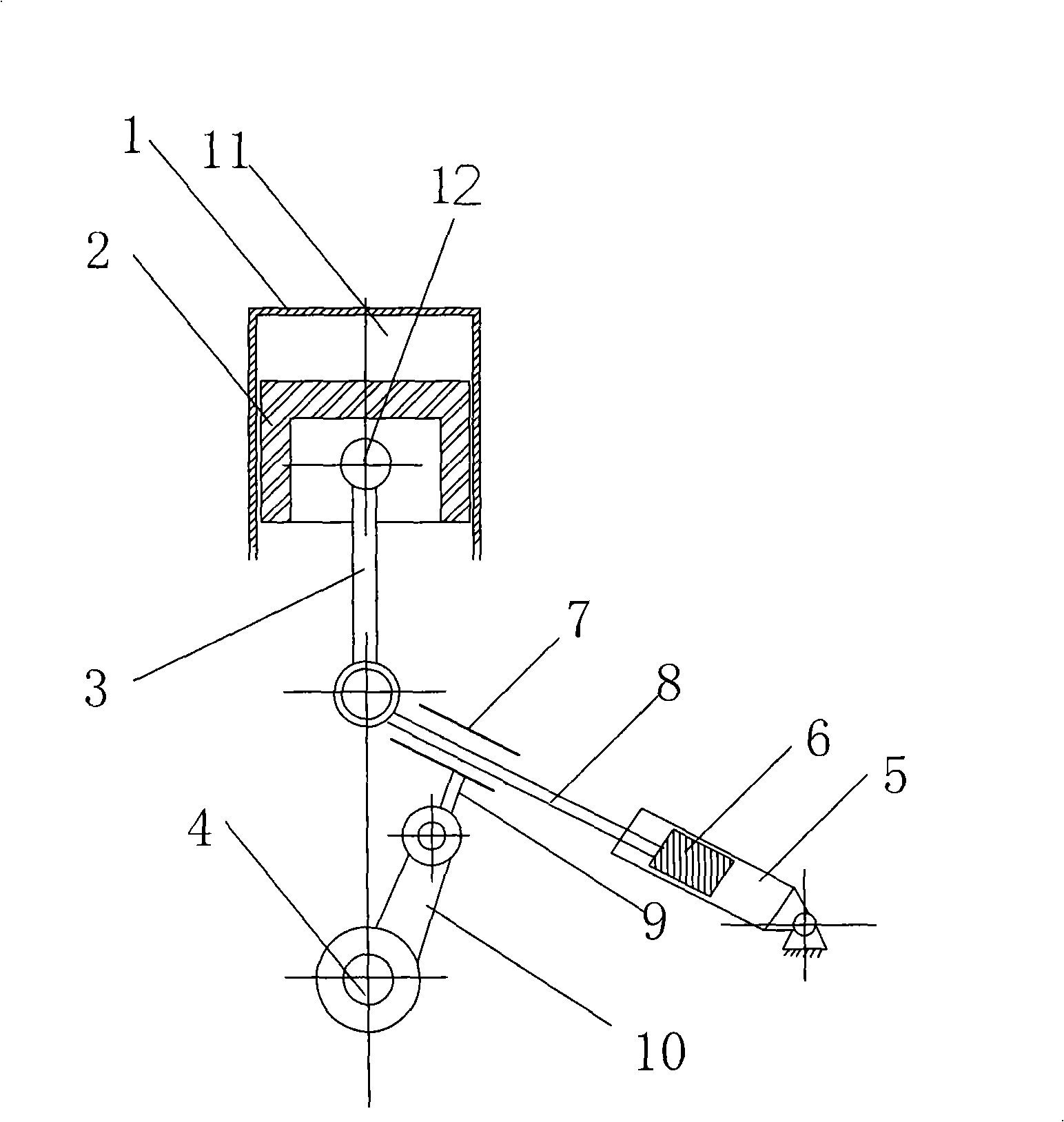

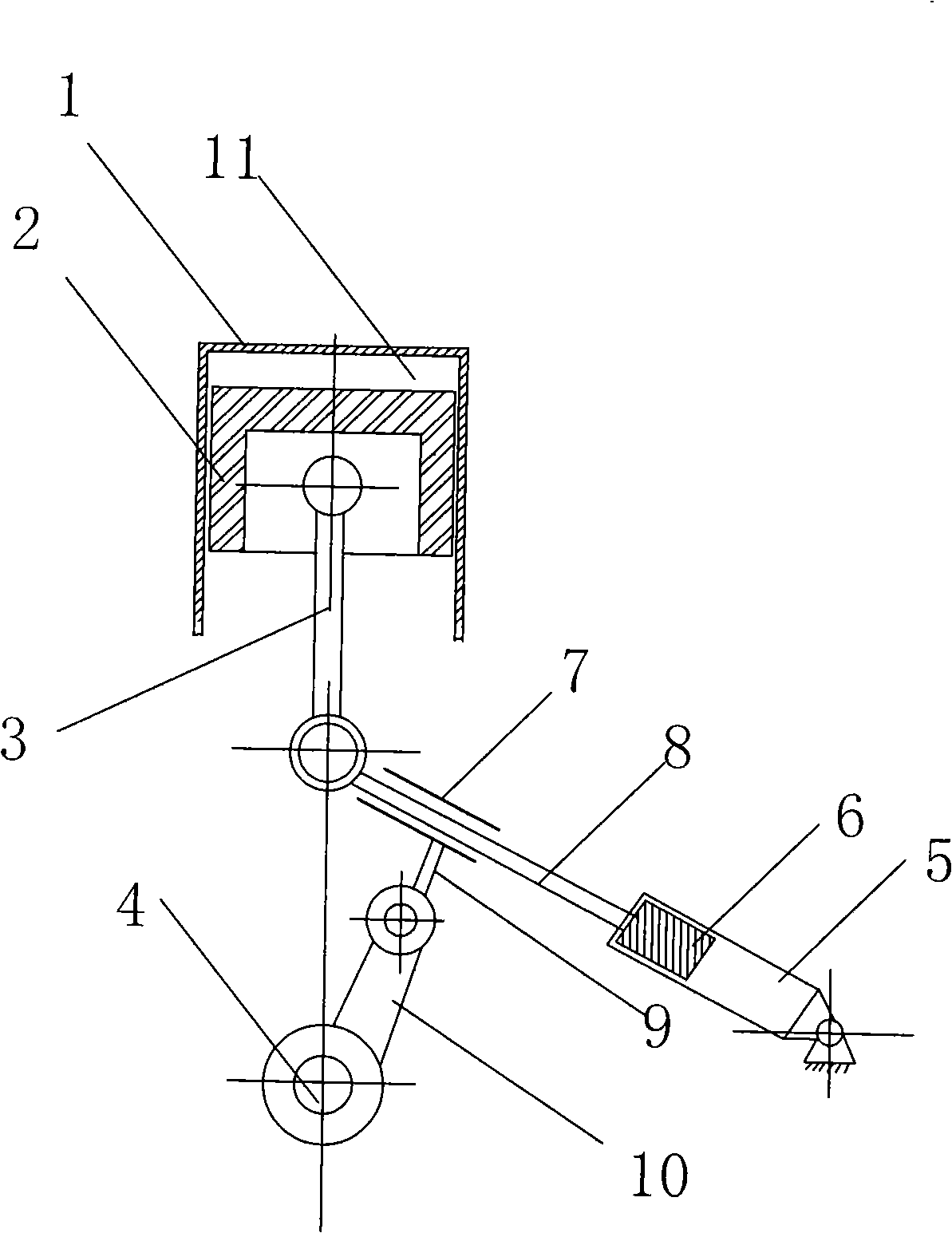

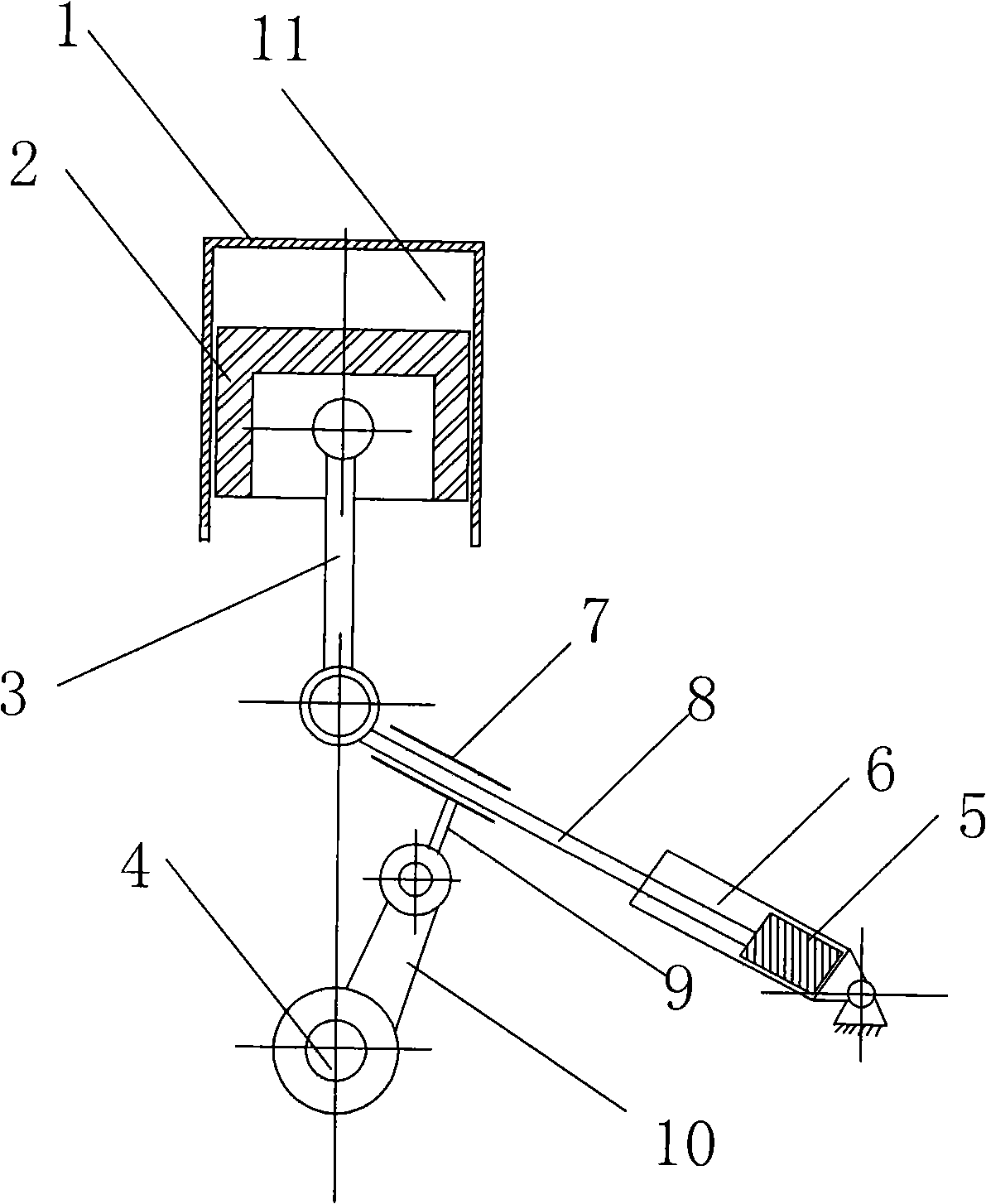

[0014] Such as figure 1 Shown: a variable compression ratio engine, including the cylinder block 1, piston 2, connecting rod 3 and crankshaft 4, the piston 2 is in the cylinder, the cylinder is in the upper part of the entire cylinder block 1, and the piston 2 can be placed in the cylinder The connecting rod 3 is connected to the crankshaft 4 and the piston 2, and the connecting rod 3 is movably connected to the piston 2 through the piston pin 12. In this embodiment, a variable effective length of the connecting rod 3 is also set on the cylinder 1. mechanism, the two ends of the effective length of the variable connecting rod 3 are connected with the connecting rod 3 and the crankshaft 4 respectively. Since the connecting rod 3 connects the crankshaft 4 and the piston 2, the reciprocating linear motion of the piston is converted into a rotary motion through the crankshaft, and its effective length is the distance from the center of the crankshaft to the center of the piston pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com