Measurement method and apparatus for fast detection of textile moisture content

A measuring device and textile technology, applied in the direction of weighing by removing certain components, can solve the problems of stability and accuracy of results, many interference factors, and deviations in results, etc., and achieve easy portability, compact structure, and mechanism simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

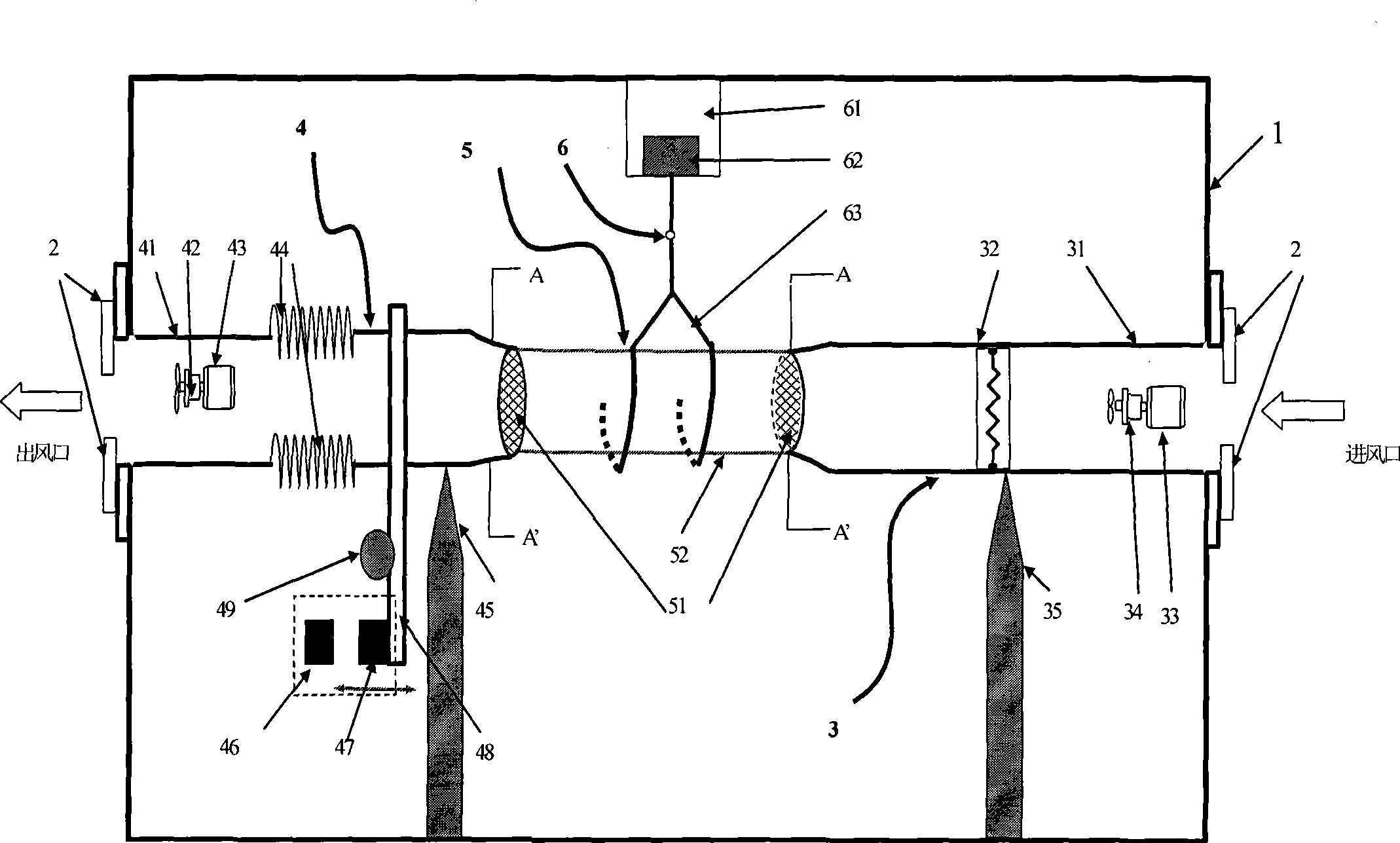

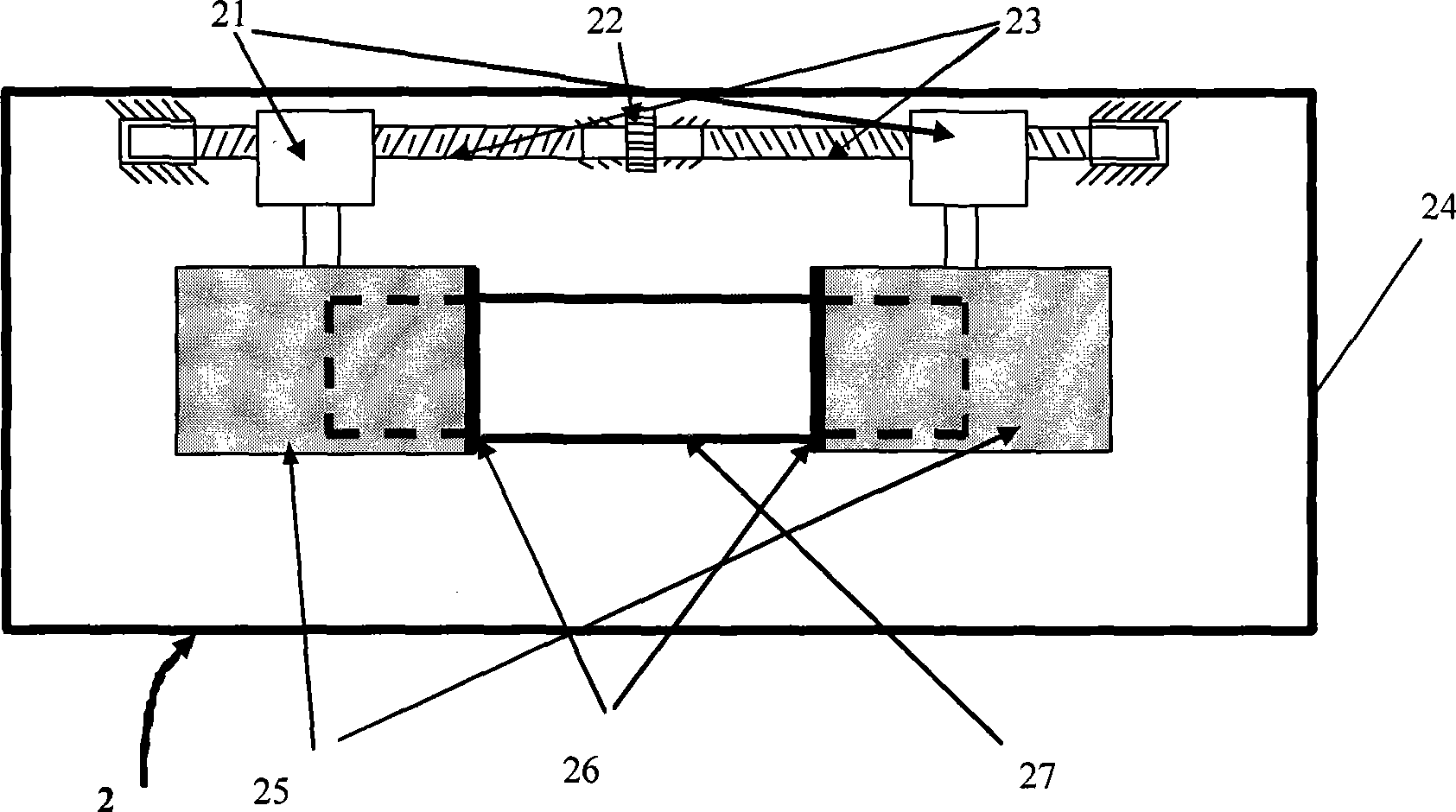

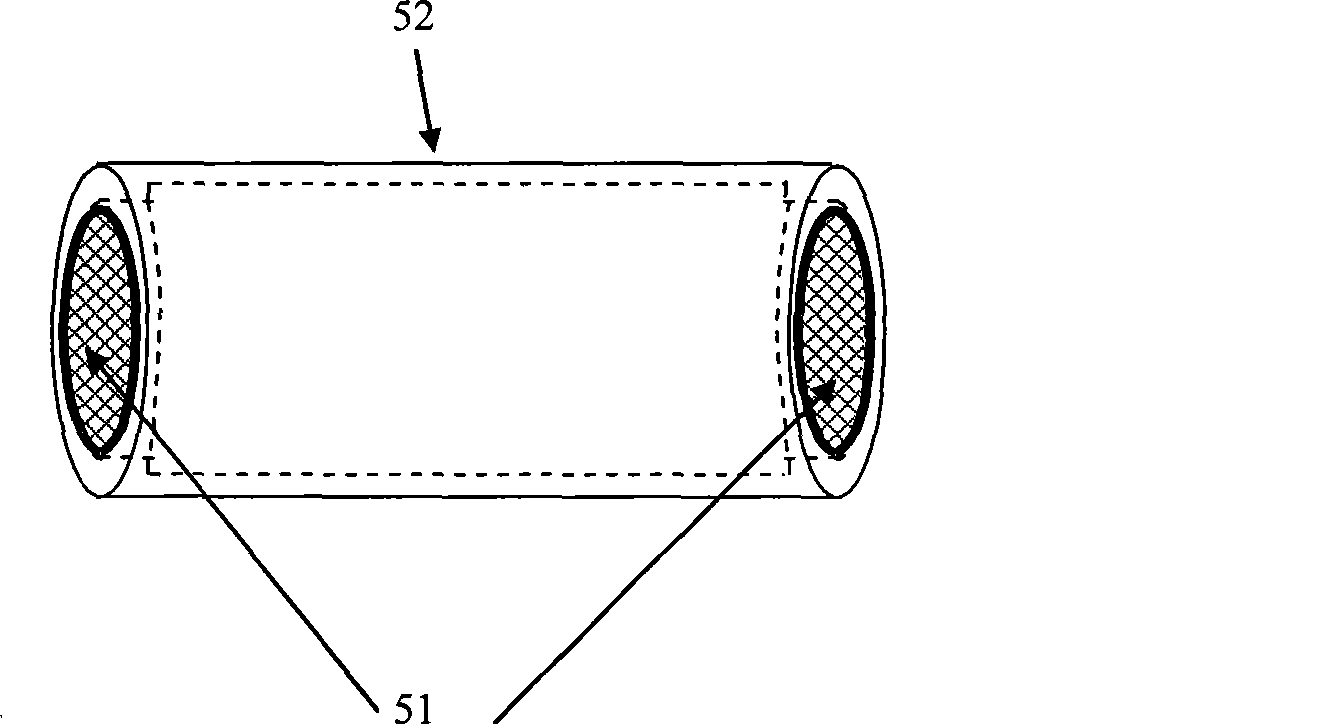

[0035] Embodiment 1 Cotton moisture content measurement

[0036] First weigh the quality of the sample container 5 without the sample to be 10g; take the cotton sample and put it in the sample cup 52, connect and couple the sample cover 51 with the sample cup 52; then put the sample container 5 in the hook 63, and weigh 15.2g; adjust the air extraction and exhaust flow area of the air extraction system 3 and exhaust system 4 to be 100cm 2 The temperature of starting induction cooker 32 heating and sucking air is 105 ℃ ± 5 ℃; Start fan 34 and fan 42, regulate gas flow rate, promptly adjust the flow rate of the suction and exhaust of air extraction system 3 and exhaust system 4 to be 10cm / s; the starter relay 46 attracts the electromagnet 47, drives the handle 48 to reciprocate once per second to drive the hollow tube 41 to push and compress the sample container 5 horizontally, so that the sample container 5 is connected with the air extraction system 3 and the exhaust system...

Embodiment 2

[0037] Embodiment 2 wool fiber moisture content measurement

[0038] First weigh the quality of the sample-holding cylinder 5 without sample to be 10g; connect and couple the sample-holding cover 51 with the sample-holding cup 52 one side, get the rough sample and put it in the sample-holding cup 52, and connect the sample-holding cover 51 and the sample-holding cup 52 The sample holding cup 52 is connected and coupled; then the sample holding cylinder 5 is placed on the hook 63, and the weight is 15.2g; the air extraction and exhaust flow areas of the air extraction system 3 and the exhaust system 4 are adjusted to 100cm 2 The temperature of starting induction cooker 32 heating and sucking air is 105 ℃ ± 5 ℃; Start fan 34 and fan 42, regulate gas flow rate, promptly adjust the flow rate of the suction and exhaust of air extraction system 3 and exhaust system 4 to be 10cm / s; the starter relay 46 attracts the electromagnet 47, drives the handle 48 to reciprocate twice per seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com