Device and method for measuring moisture regain of loose fiber assembly

A technology of fiber aggregates and measuring devices, applied in the direction of removing certain components, weighing, drying solid materials, and heating to dry solid materials, etc., to achieve rapid measurement and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

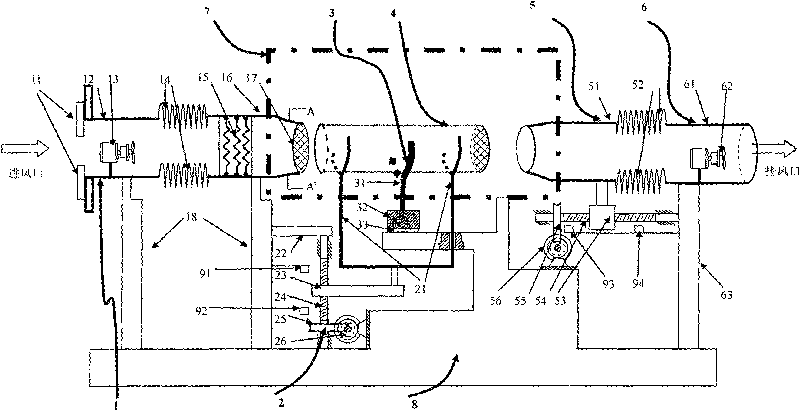

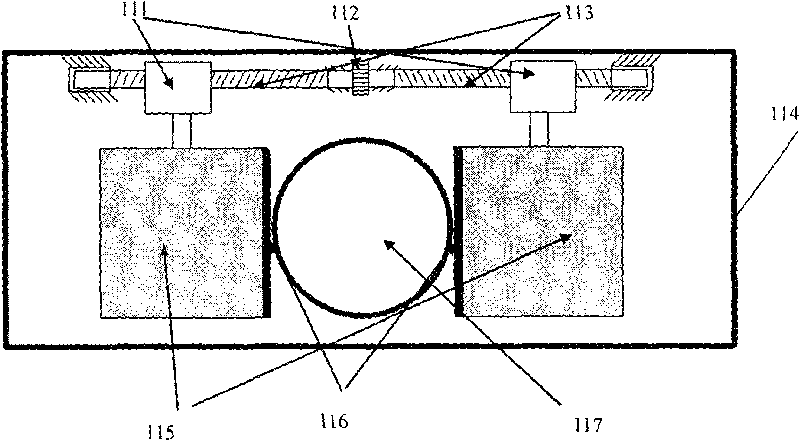

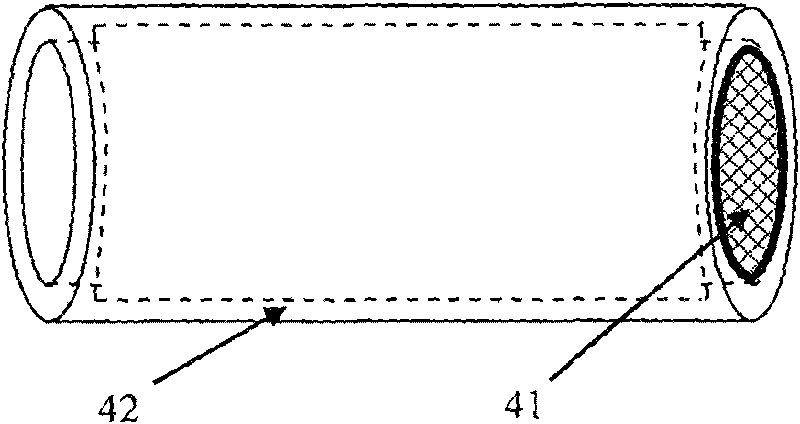

[0066] Embodiment 1 viscose moisture regain measurement

[0067] The steps for measuring the moisture regain of viscose are as follows: ①Weigh the mass of the sample cylinder 4 without the sample to be 11.000g; connect and couple the sample cover 41 with the sample cup 42 side, and take the sample and put it in the sample cup 42; 2. the starter motor 56 drives the worm screw 55 and the screw mandrel 54 to rotate, and drives the third hollow tube 51 and the slide block 53 to move horizontally to the right limit position 94; the starter motor 26 drives the worm screw 25 and the screw mandrel 24 to rotate, Drive the Y-shaped bracket 21 and the slider 23 to move upward to the upper limit 91; place the sample container 4 on the Y-shaped bracket 21 on the lifting mechanism 2; ③ start the motor 56 to drive the worm 55 and the screw 54 to rotate, Drive the third hollow tube 51 and the slider 53 to move horizontally to the left, and push the sample container 4 to move horizontally to t...

Embodiment 2

[0070] Embodiment 2 Wool moisture regain measurement

[0071] According to the test method of embodiment 1, first weigh the quality G of the sample holder 4 without sample 0 It is 11.000g; weigh the sample container containing the sample 4 mass G 1 is 15.910g; adjust the suction flow area of input mechanism 2 to 150cm 2 ;Start the induction cooker 15 through the driving system to heat and draw in the gas, and the temperature of the heating gas is 105°C±5°C; start the fan 13 and the fan 62 to adjust the gas flow rate to 0.1 m / s; ⑦After setting t1 to 360 seconds, weigh and install the test Sample container 4 quality G 2 It is 15.395g; ⑧ after setting for 120 seconds; repeat steps ⑦ and ⑧ until the weighing quality of the sample cylinder 4 is constant weight G 3 It is 15.400g. The quality-time curve corresponding to wool regain measurement is shown in the figure below. The correction coefficient a is -0.9961, and the moisture regain of the loose wool fiber aggregate can be...

Embodiment 3

[0073] Embodiment 3 polyester moisture regain measurement

[0074] According to the test method of embodiment 1, first weigh the quality G of the sample holder 4 without sample 0 It is 11.000g; weigh the sample container containing the sample 4 mass G 1 is 16.930g; adjust the suction flow area of input mechanism 2 to 400cm 2 Start the induction cooker 15 through the driving system to heat and draw in the gas, and the temperature of the heating gas is 105°C ± 5°C; start the fan 13 and the fan 62 to adjust the gas flow rate to 0.1 m / s; ⑦ After setting for 360 seconds, weigh the sample Sample cylinder 4 quality G 2 . The quality-time curve corresponding to the polyester moisture regain measurement is shown in the figure below. 3 weighing results G 3 They are 16.924, 16.902, 16.882 respectively, and the sample masses are 5.924, 5.902, 5.882 respectively (the coefficient of variation of sample mass is 0.356%), G 3 The average result is 16.903, the correction coefficient a i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correction factor | aaaaa | aaaaa |

| correction factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com