Stator for rotating electrical machine, part to be used for stator and method for manufacturing stator for rotating electrical machine

A technology for a rotating electrical machine and a manufacturing method, which is applied to the components used in the stator, the manufacturing of the stator, and the field of the stator, can solve problems such as damage to the insulation, and achieve the effect of improving the filling factor, taking into account the filling factor, and ensuring the insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the following description, the same reference numerals are assigned to the same components. The names and functions of these parts are also the same. Therefore, detailed descriptions of these components are not repeated.

[0055] The stator of the present embodiment is a stator of a rotary electric machine including a stator and a rotor formed of permanent magnets. In this embodiment, the stator is a stator of a three-phase AC synchronous rotating electrical machine with 21 poles, but the present invention is applicable to a stator wound with coils, and is not particularly limited to 21 poles, and is not limited to three The stator of an AC synchronous rotating electrical machine.

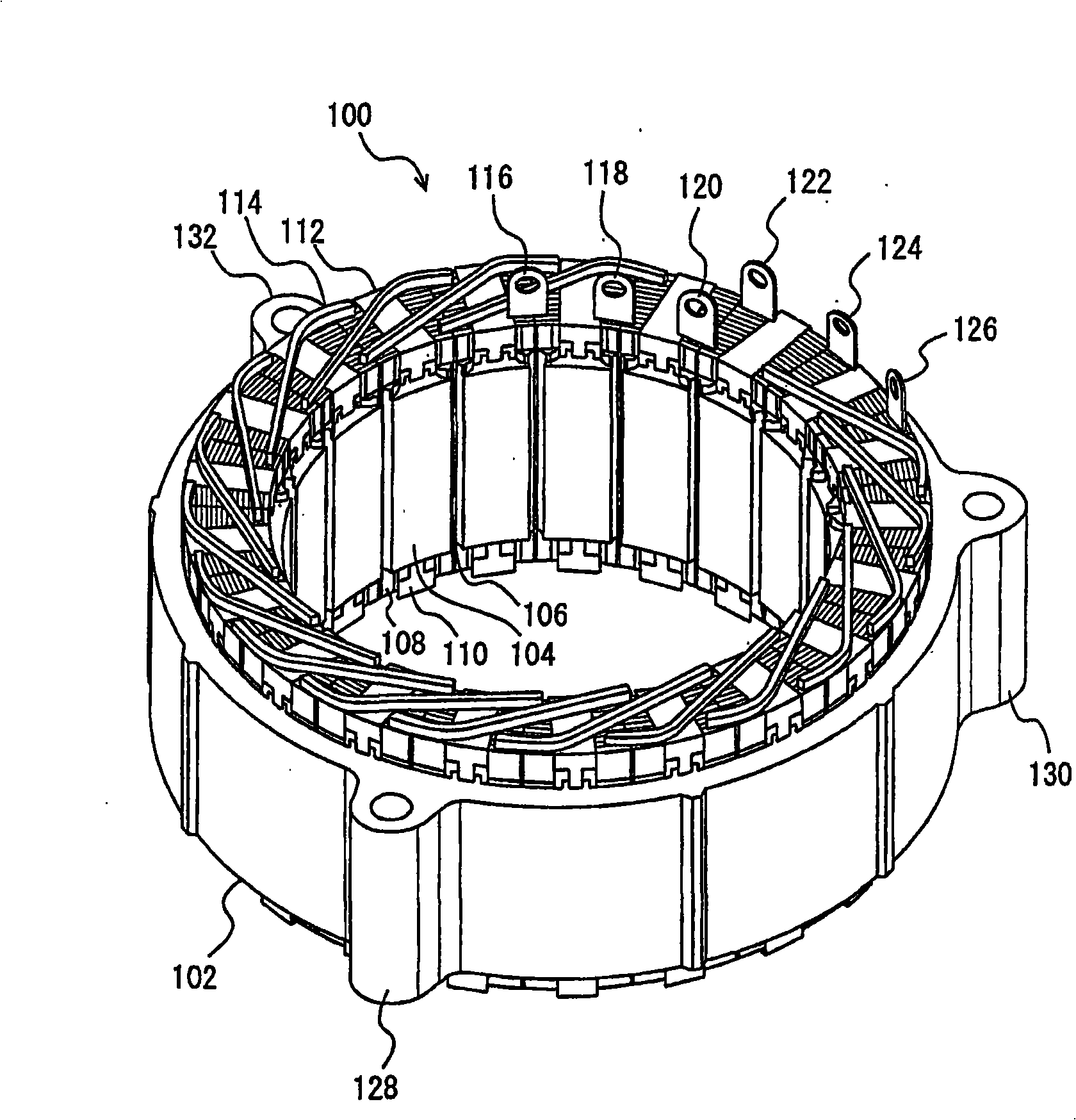

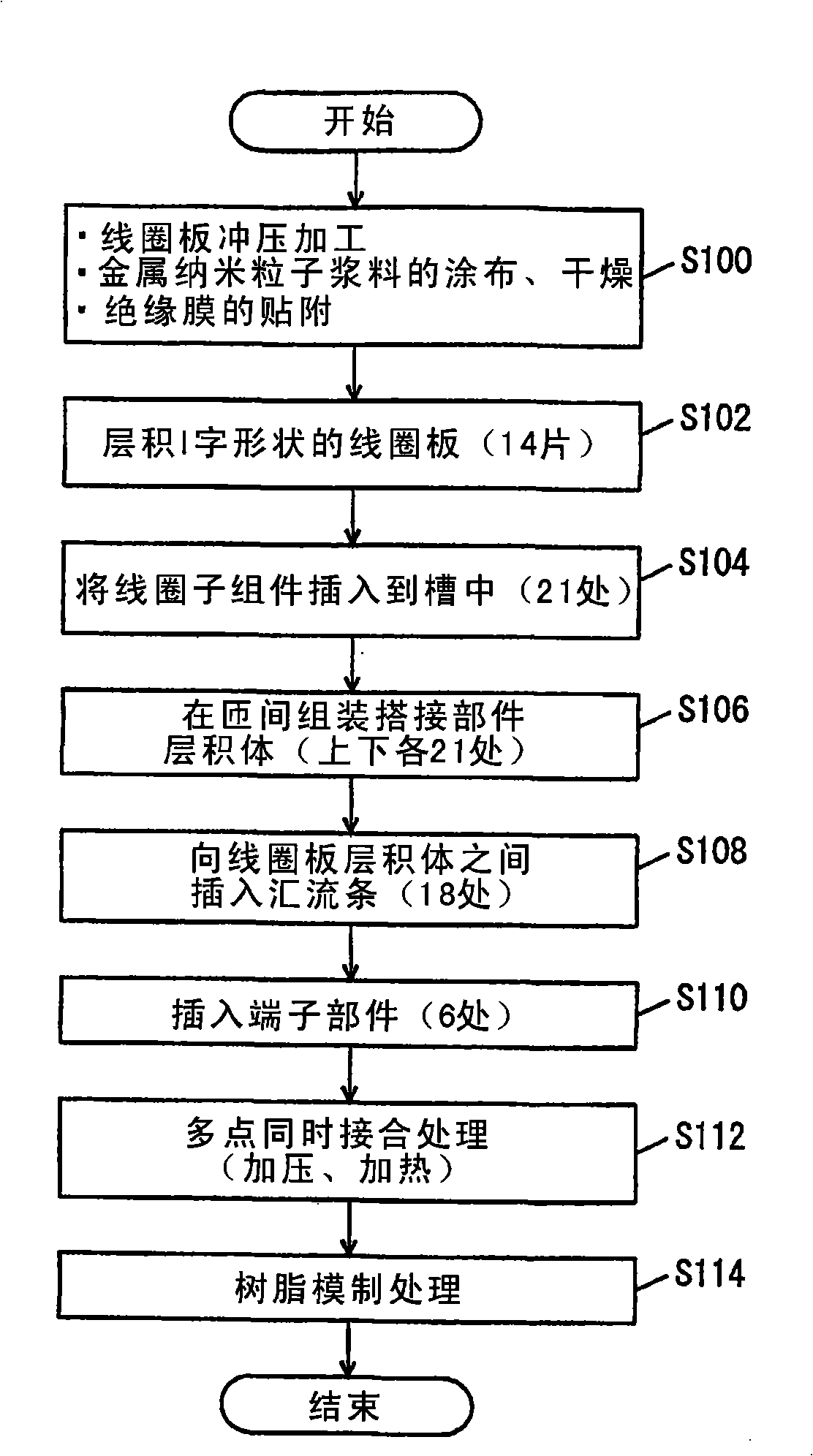

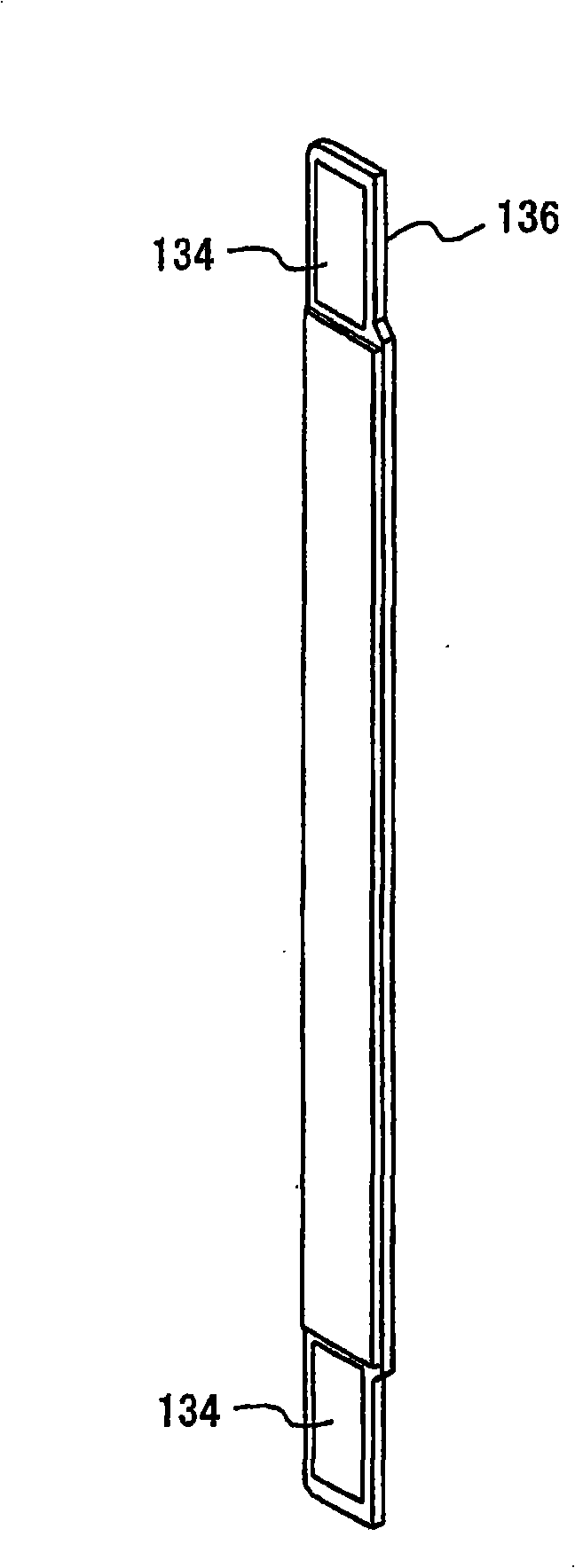

[0056] Such as figure 1 As shown, the stator 100 includes a stator core 102 , a coil subassembly 108 , laminates 110 , 112 as bridging members, and bus bars 114 .

[0057] The stator c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com