Tension side-fixing bone plate for olecranon process of ulna

A technology of olecranon and bone plate, applied in the direction of fixator, outer plate, internal bone synthesis, etc., can solve the problems of cumbersome surgery, long time, large trauma, etc., achieve convenient operation, enhance stability, and reduce incidence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

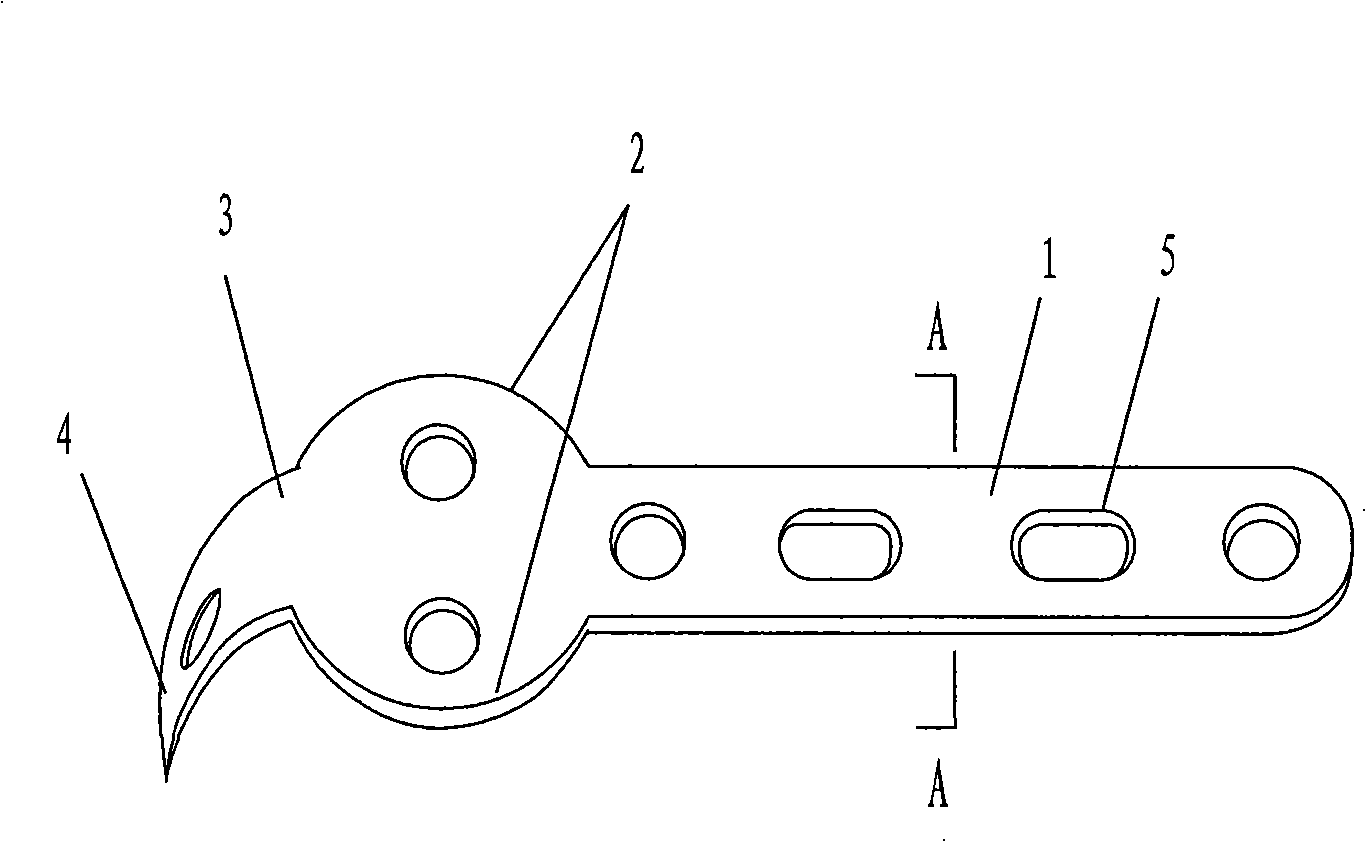

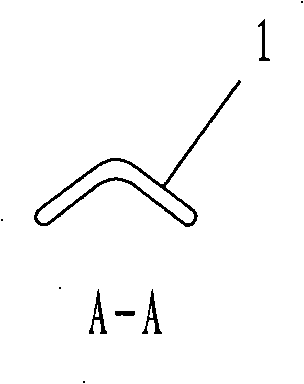

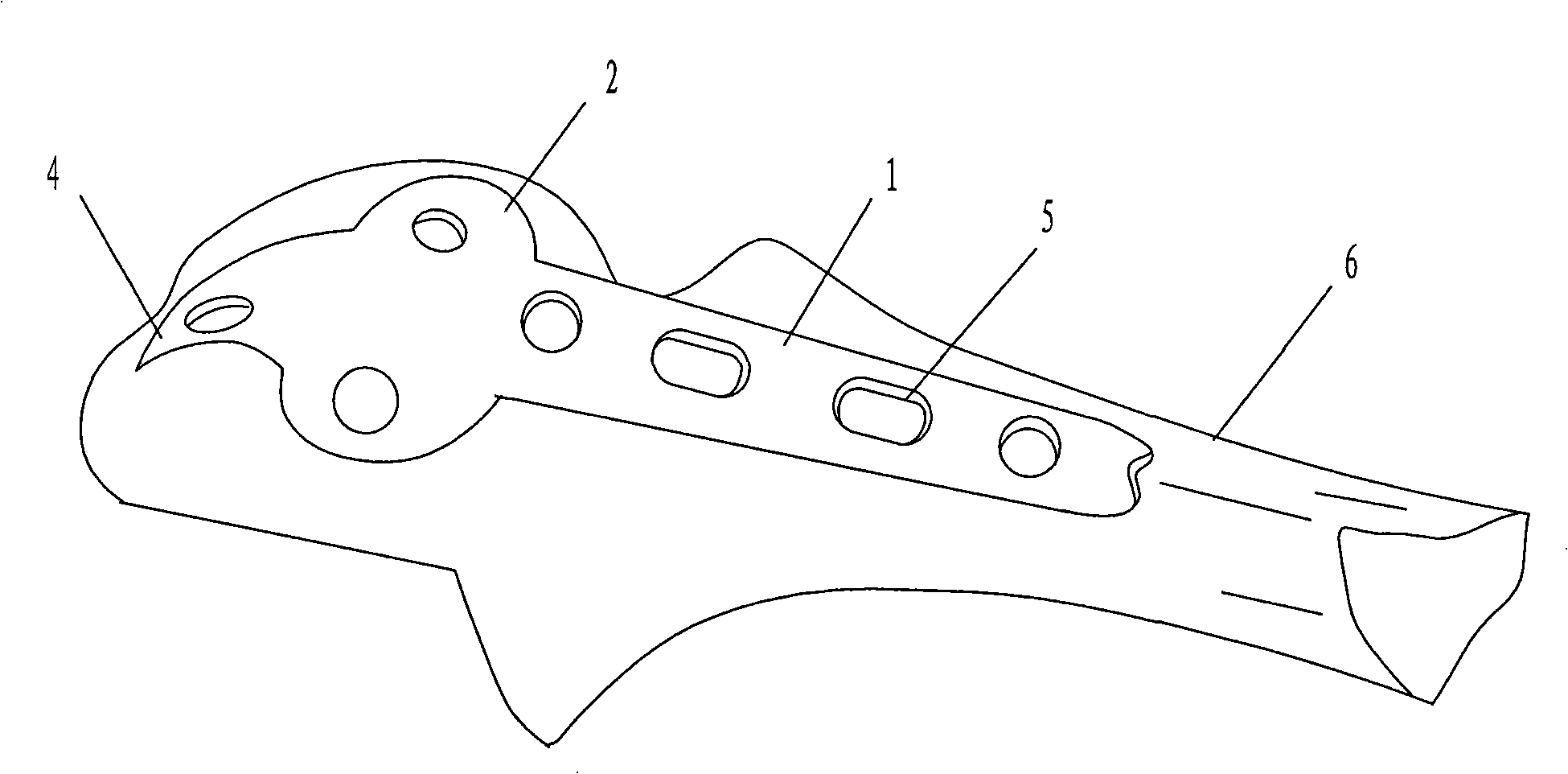

[0015] As shown in the figure, the steel plate body 1 of the olecranon olecranon bone plate of the present invention is designed according to the anatomical shape of the ulnar ridge using an angle steel plate, and the starting point of bending is the lower edge of the semicircular abduction protrusion 2 until the plate body 1, the angle gradually changes from proximal to distal from 110° to 80°, which is consistent with the anatomical shape of the ulnar crest. After adopting this shape, the plate body is covered on the ulnar crest during the operation, and the implanted nail is implanted and fixed, so as to realize the real tension side fixation, enhance the stability of the fracture fixation, and facilitate the healing of the fracture.

[0016] The figure also shows that on the basis of the existing olecranon bone plate, the elbow 3 is changed into a head hook 4 arc-shaped design, so that the arc conforms to the anatomical shape of the normal human olecranon. It is easy to pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com