Artificial blood vessel bracket and preparation method thereof

A technology of artificial blood vessels and vascular stents, which is applied in the field of artificial vascular stents and its preparation, can solve the problems that drug stents do not improve the survival rate and death of patients, and achieve the effects of low price, reduced manufacturing costs, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

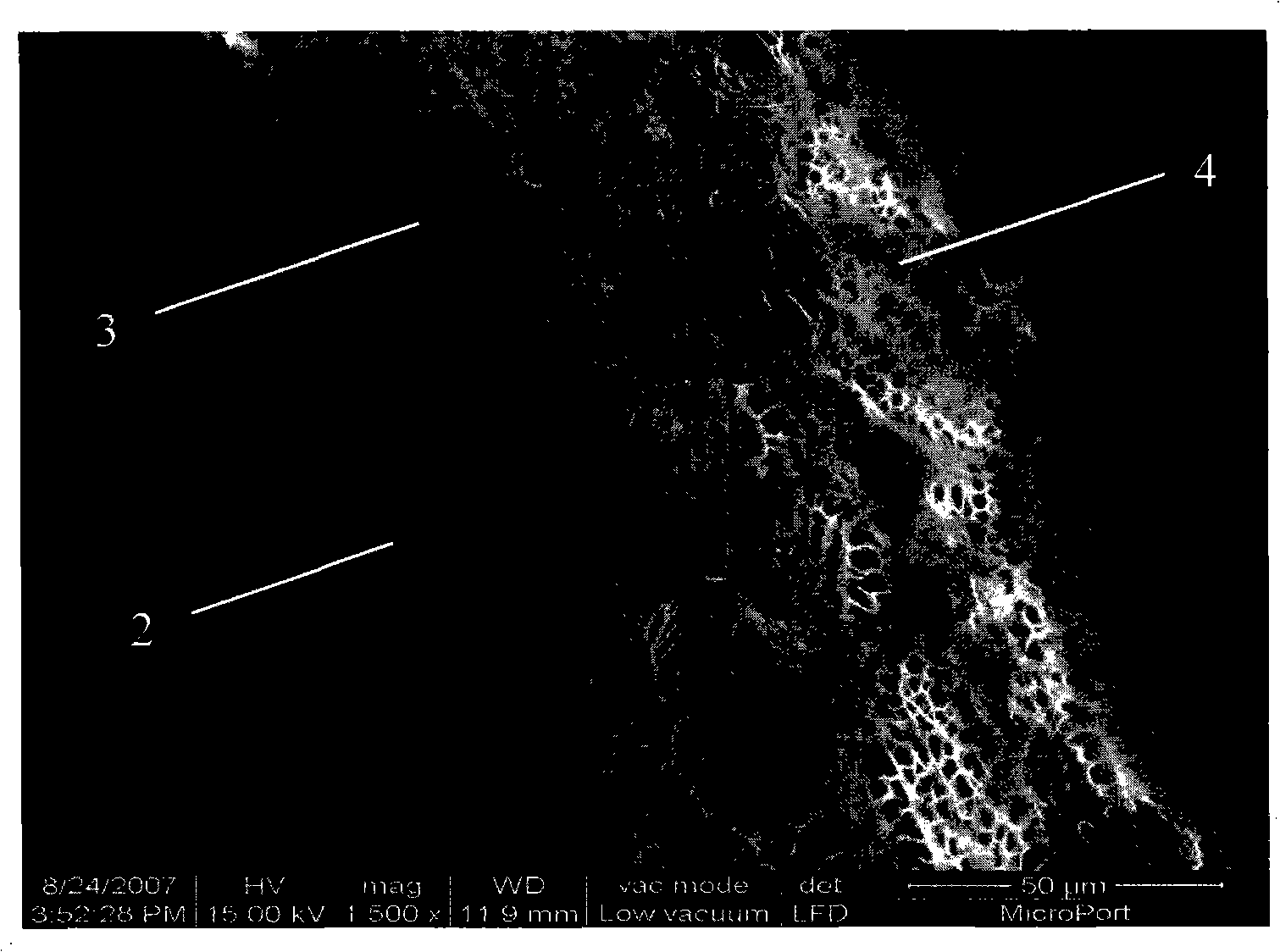

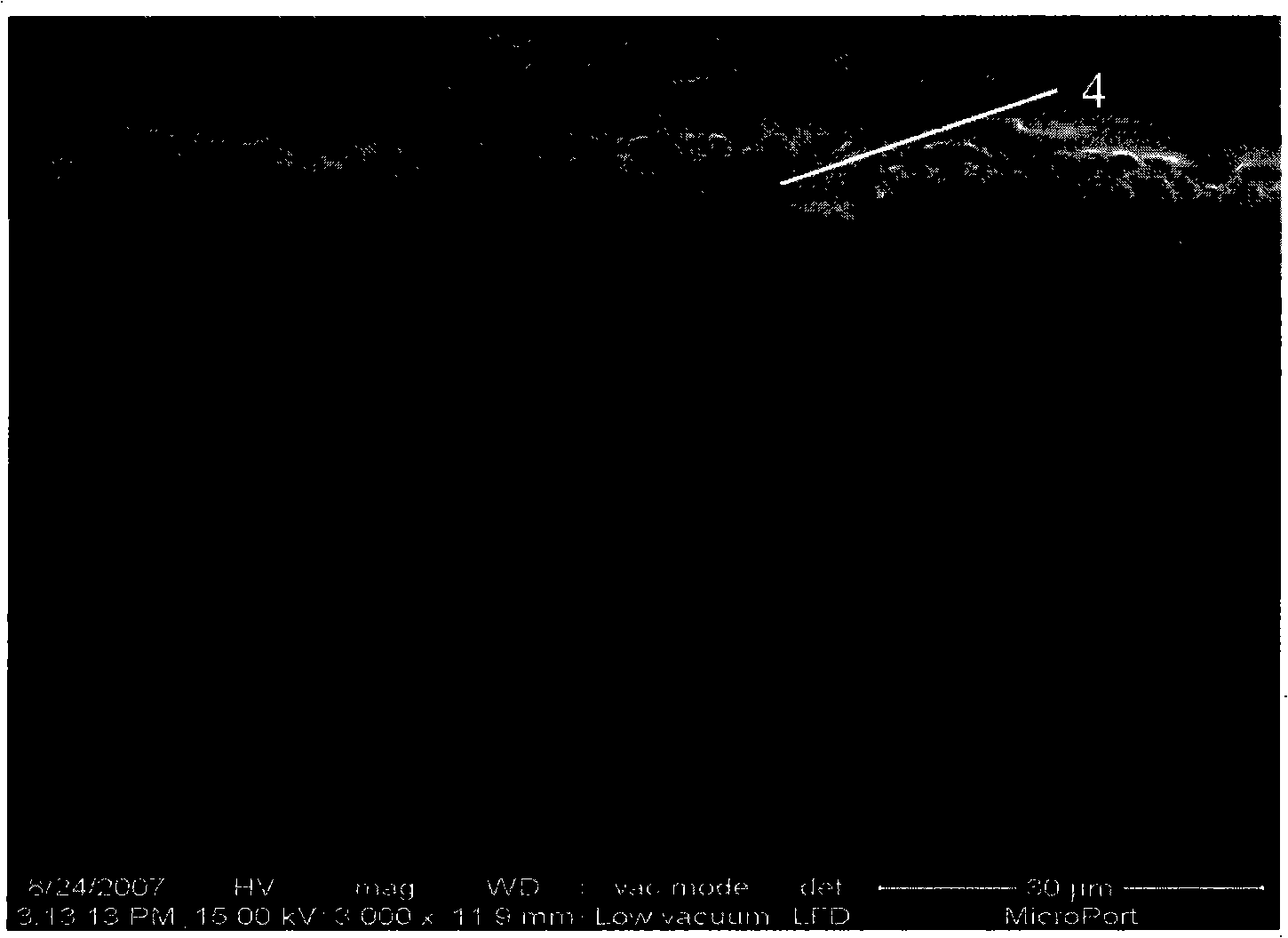

Embodiment 1

[0044] Add 5g silk into 200ml, 2% sodium carbonate aqueous solution, treat at 98°C for 60min, repeat 3 times, dissolve with 50% lithium bromide aqueous solution after drying, and then filter the above solution with multi-layer non-woven fabric to remove impurities, and then repack Put it into a dialysis bag and dialyze with running water for three days to obtain a 1.5% silk protein solution. The body of the stainless steel vascular stent is washed with acetone and pure water respectively, dried in the air, and then the fibroin solution is evenly sprayed on the body of the stent. The coated stents were placed in a vacuum oven and dried at 37°C for 24 hours. Put the coated stent in analytically pure ethylene glycol, treat it for 72 hours, wash it with distilled water, and then dry the coated stent in a vacuum drying oven at 37°C for 24 hours, and the dense bottom layer formed by silk protein can be attached to the vascular stent body .

Embodiment 2

[0046] Prepare 100 ml of 20% silk protein aqueous solution, then add 100 ml of 10% gelatin aqueous solution, mix evenly, refrigerate and centrifuge at high speed, and collect the supernatant. Immerse the stainless steel stent body in the above mixed solution, dry it at 20°C for 20 hours after dipping, repeat the above steps until the coating weight reaches 1000ug, so as to form a uniform coating on the surface of the stent body, and then apply the coating The stent was treated in 25% glycerol aqueous solution for 1 hour. Wash the stent with water, put the coated stent in a vacuum oven, and dry it under vacuum at 60° C. for 12 hours. Then place the coated stent in pure water, boil for 2 hours, repeat 3 times until the gelatin in the coating is completely dissolved, wash with water, and dry to obtain a vascular stent with uniform pores in the coating, adjust the ratio of silk and gelatin , vascular stents with different porosity in the coating can be obtained.

Embodiment 3

[0048] Prepare 5% silk protein aqueous solution, adopt the method of spraying to coat the surface of the stent body, the solution flow rate is 0.25ml / min, the spray time is 30 seconds, repeat the above steps until the weight reaches 200ug, and form a continuous bottom layer on the surface of the stent body after drying. The stent containing the bottom layer was treated in 80% ethanol aqueous solution for 24 hours, washed with water, and vacuum-dried at room temperature. Then spray a mixed solution containing 5% silk protein and 2.5% chitosan on the bracket containing the bottom layer until the coating weight reaches 1000ug, and then dry naturally. Then soak the stent with water, quickly place it in a -80°C ultra-low temperature refrigerator to freeze for 2 hours, and then quickly transfer it to a pre-cooled freeze dryer and freeze-dry it for 18 hours to form a coating structure with micropores. Then, the above-mentioned coated stent with micropores was placed in an electric co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com