Reclaimed rubber refining unit

A technology of a refiner and reclaimed rubber, which is applied in the field of devices for producing reclaimed rubber, can solve the problems that the reclaimed rubber cannot achieve high-quality rubber properties, and the utilization of reclaimed rubber is limited, so as to improve the strength and elongation rate, and improve the strength and tensile strength. The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail:

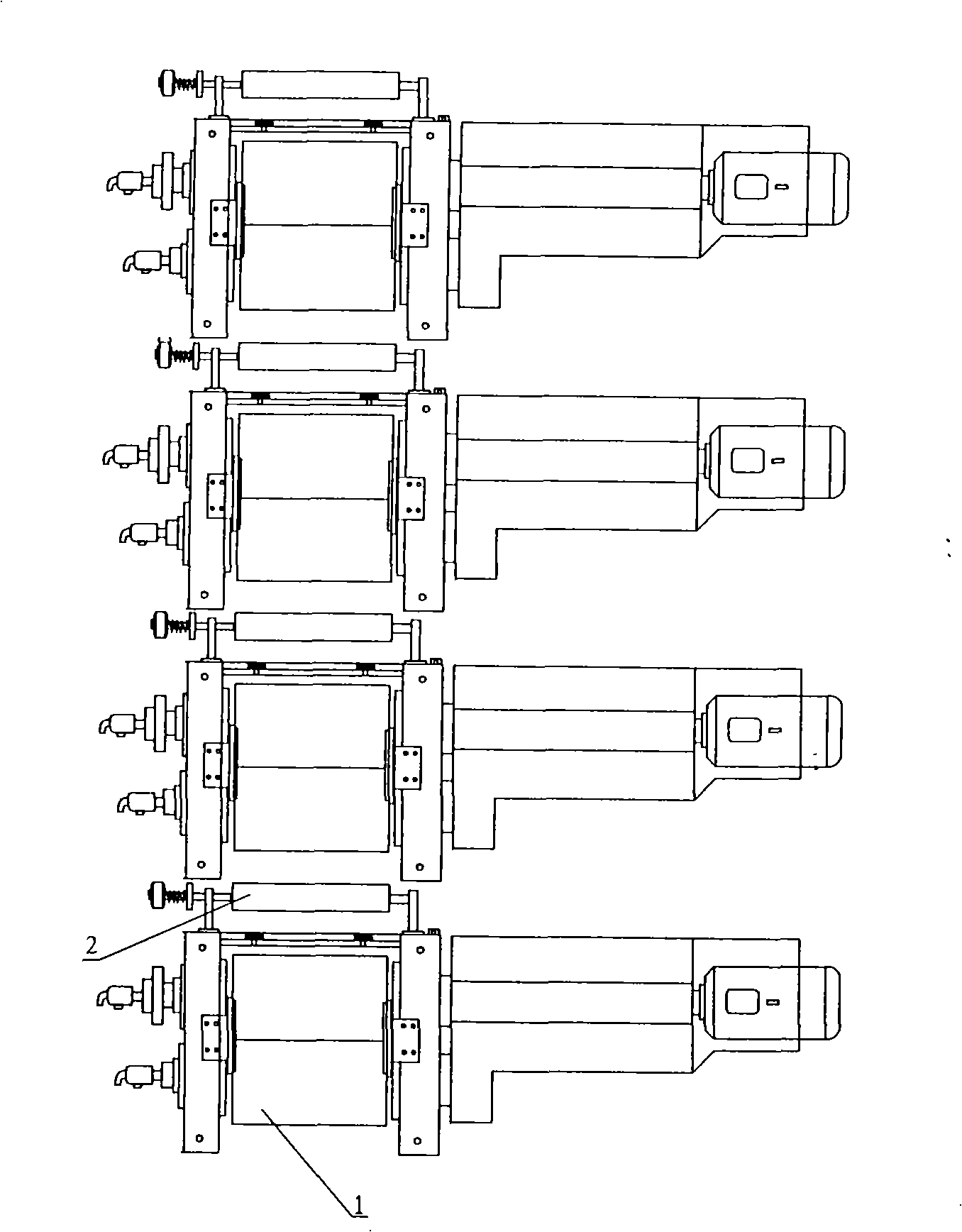

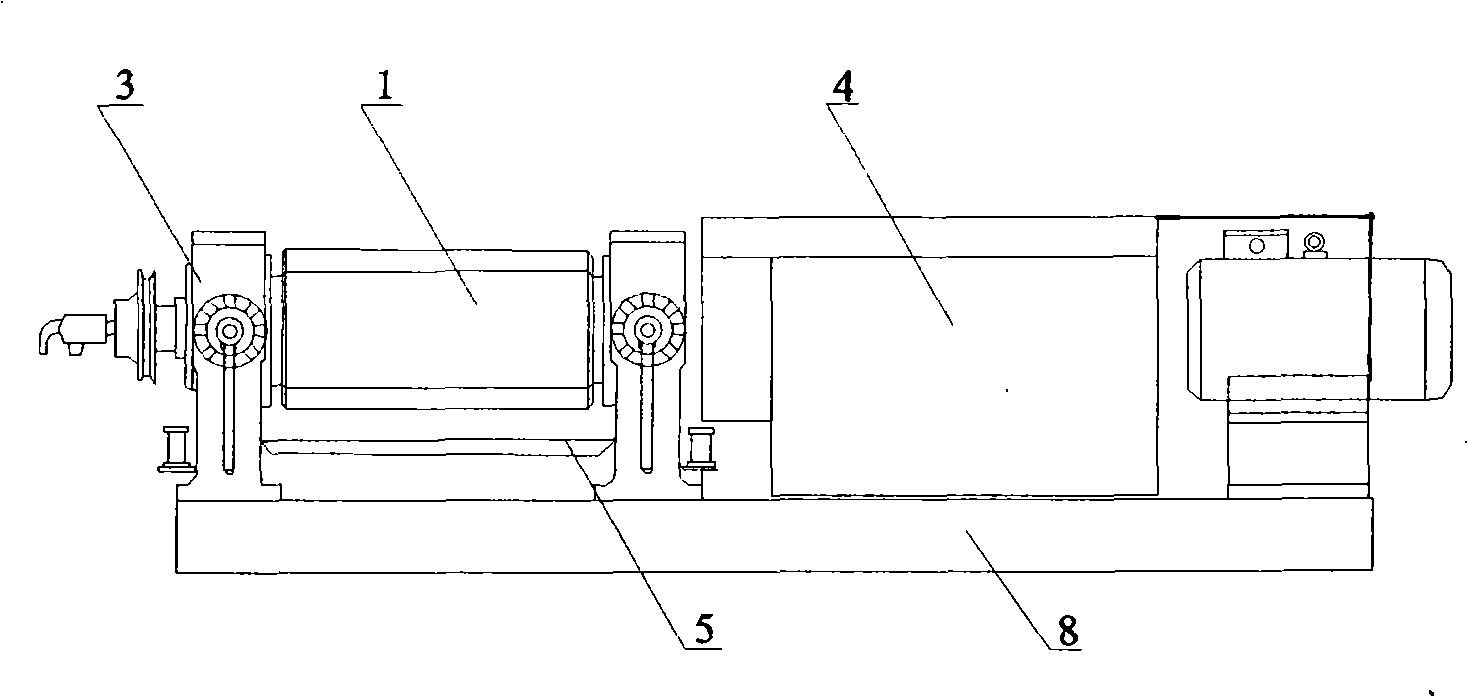

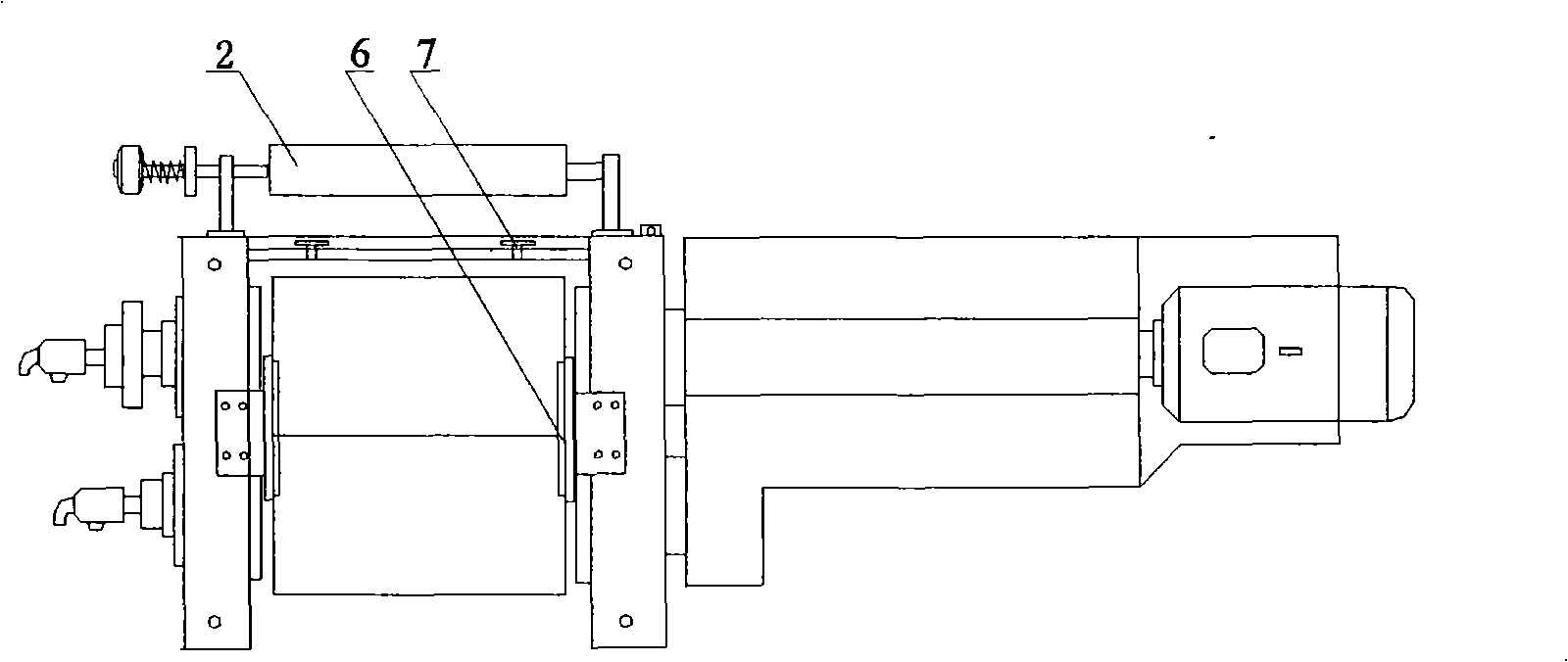

[0013] Such as figure 1 As shown, the reclaimed rubber refining unit consists of four refining machines. The following takes a refining machine as an example to describe in detail, see figure 2 , 3 , the refiner frame 3 is set on one side of the base 8, a pair of extruding rollers 1 are arranged on the frame, and rubber stoppers 6 are arranged at the middle of both ends of the pair of rollers, and the rubber stoppers are used to prevent leakage of raw materials . The lower end of the roller is provided with a rubber disc 5 . A rubber scraper 7 is installed on the rubber outlet side of the refiner to scrape off the excess part of the produced reclaimed rubber, so that the regenerated rubber can enter the next refiner in a regular shape. The outside of the rubber scraper is provided with a support roller 2 for sending the reclaimed rubber to the next refiner. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com