Hairiness-shaped composite yarn

A composite yarn and yarn technology, applied in the direction of yarn, textile and papermaking, can solve the problems of easy pilling, affecting wearing comfort and visual effect, and achieve the effect of excellent anti-pilling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

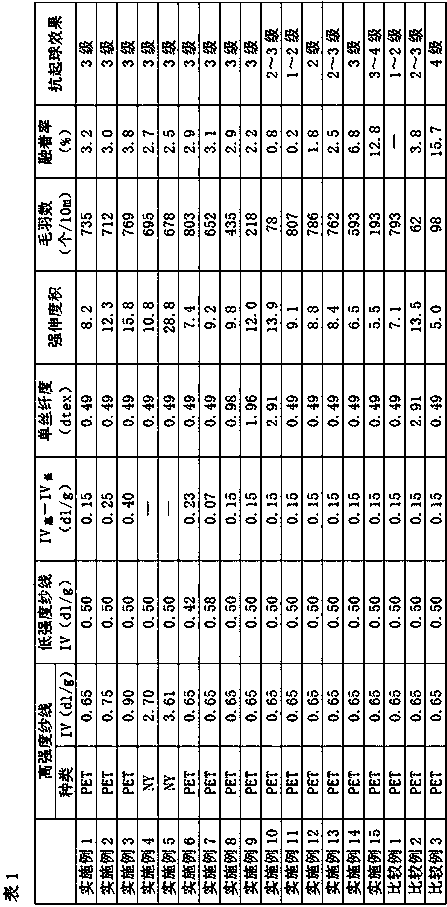

Embodiment 1

[0051] Polyethylene terephthalate (high-strength part) with an IV of 0.65dl / g and polyethylene terephthalate (low-strength part) with an IV of 0.50dl / g are respectively spun to produce high Strength POY and low strength POY, the obtained low strength POY is combined with the high strength POY at the yarn guide after external drafting, enters the false twist zone at 160~240℃, and after interlacing, the monofilament size is obtained 0.49dtex hairy composite yarn (140T-288-DTY).

[0052] The hairiness-like composite yarn obtained by the above method has a strength and elongation product of 8.2, and the number of hairiness of the hairiness-like composite yarn with a length of 1 mm and above is 735 pieces / 10 meters. The fusion rate of the hairy composite yarn is 3.2%, and the anti-pilling effect is level 3.

Embodiment 2

[0054] Polyethylene terephthalate (high-strength part) with IV of 0.75dl / g and polyethylene terephthalate (low-strength part) with IV of 0.50dl / g are respectively spun to make high Strength POY and low strength POY, the obtained low strength POY is combined with the high strength POY at the yarn guide after external drafting, enters the false twist zone at 160~240℃, and after interlacing, the monofilament size is obtained 0.49dtex hairy composite yarn (140T-288-DTY).

[0055] The hairiness-like composite yarn obtained by the above method has a strength and elongation product of 12.3, and the number of hairiness of the hairiness-like composite yarn with a length of 1 mm and above is 712 per 10 meters. The fusion rate of the hairy composite yarn is 3.0%, and the anti-pilling effect is level 3.

Embodiment 3

[0057] Polyethylene terephthalate (high-strength part) with an IV of 0.90dl / g and polyethylene terephthalate (low-strength part) with an IV of 0.50dl / g are respectively spun to make high Strength POY and low strength POY, the obtained low strength POY is combined with the high strength POY at the yarn guide after external drafting, enters the false twist zone at 160~240℃, and after interlacing, the monofilament size is obtained 0.49dtex hairy composite yarn (140T-288-DTY).

[0058] The hairiness-like composite yarn obtained by the above method has a strength and elongation product of 15.8, and the number of hairiness of the hairiness-like composite yarn with a length of 1 mm and above is 769 / 10 meters. The fusion rate of the hairy composite yarn is 3.8%, and the anti-pilling effect is level 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile product | aaaaa | aaaaa |

| tensile product | aaaaa | aaaaa |

| tensile product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com