Warp production method and device thereof

A production equipment and warp technology, applied in the direction of yarn, textiles and paper making, can solve problems such as poor evenness, floating threads, streaks, etc., and achieve the effect of improving strength and elongation and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A kind of warp production method of the present invention is characterized in that: comprises the following steps successively:

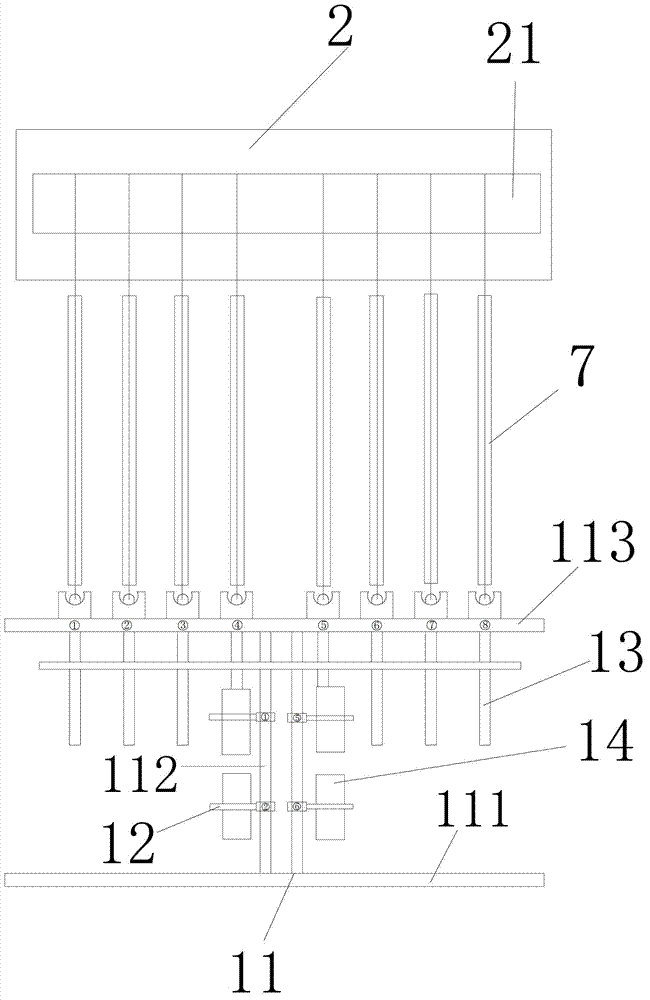

[0028] A) Cooking at high temperature: pass the raw silk through the heating roller 21, and heat the heating roller 21 to 150-200°C to form cooked silk;

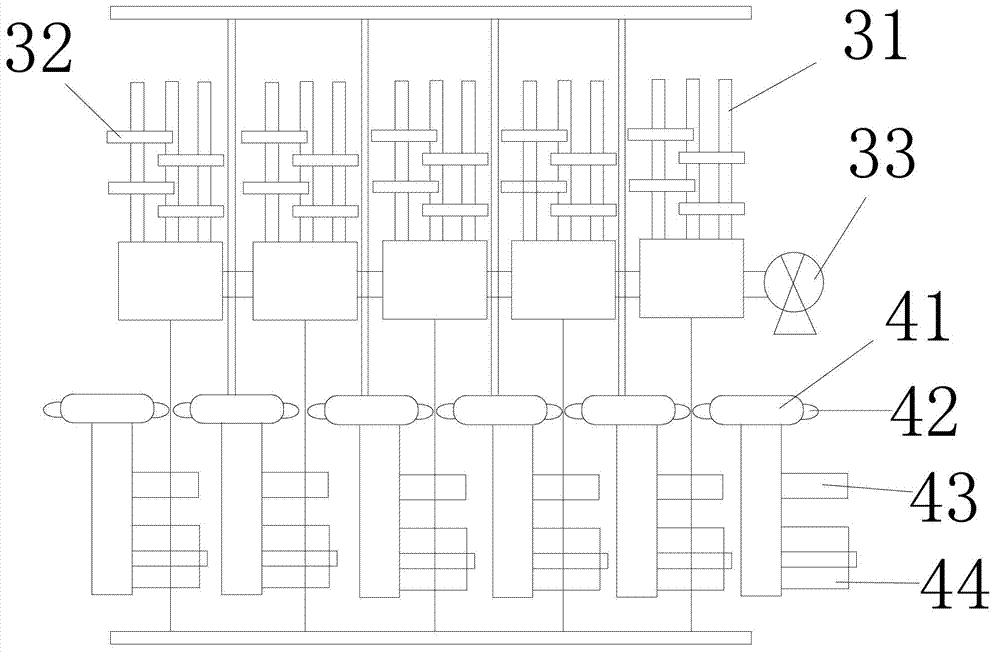

[0029] B) Twisting: Twisting the cooked silk in step A), the twist coefficient is 4.6-5.0;

[0030] C) Adding network: adding network treatment to the boiled silk that has completed the twisting operation to form warp yarn embryo yarn;

[0031] D) Rewinding: rewind the warp embryo yarn, each roll is 100-120m, forming warp yarn;

[0032] E) Warping: Warping the wound warp yarns to form finished warp yarns.

[0033] The temperature of the heating roller 21 in the step A) is 180° C., the twist coefficient in the step B) is 4.8, and each roll in the step D) is 110 m.

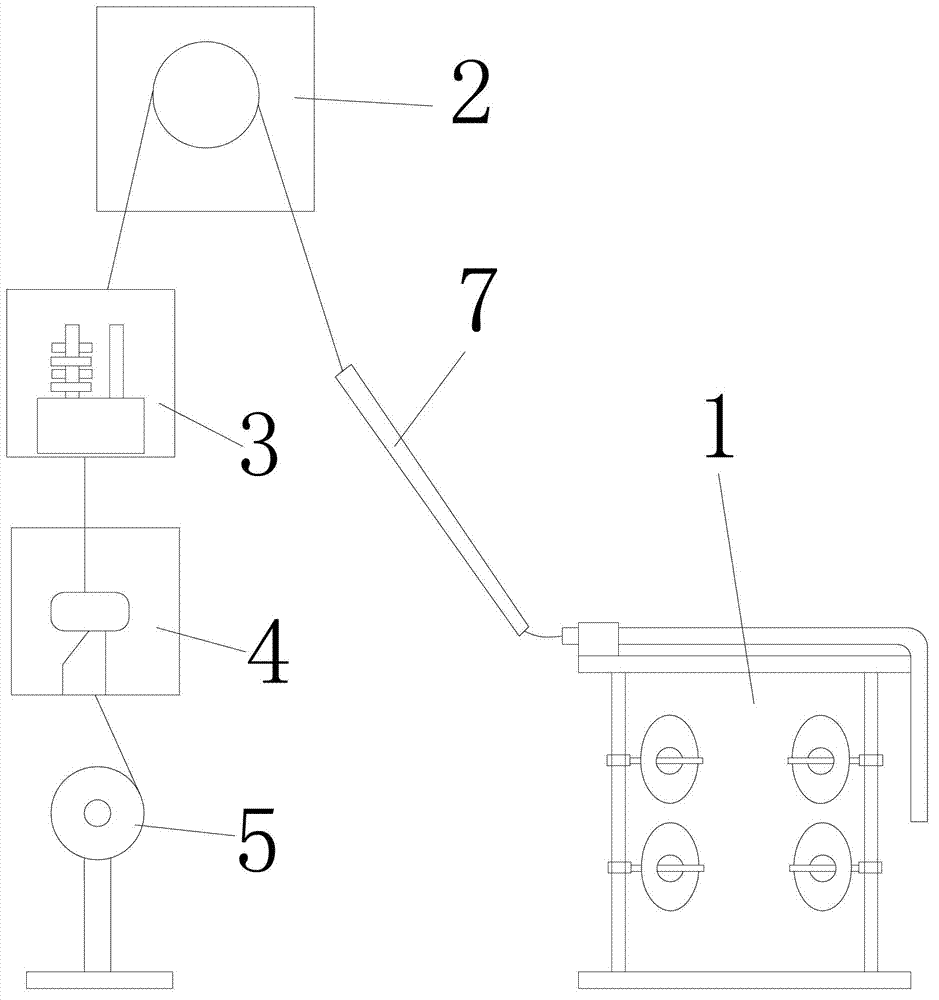

[0034] refer to figure 2 , a kind of warp production equipment of the present invention, comprises cloth guiding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com