Method for preparing complaisance type double-layer electric vortex flow sensor for testing curved surface clearance

An eddy current sensor and eddy current technology, applied in the field of sensors, can solve the problems of complex processing technology, non-attachment, and high processing conditions, and achieve high test accuracy, resolution, and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

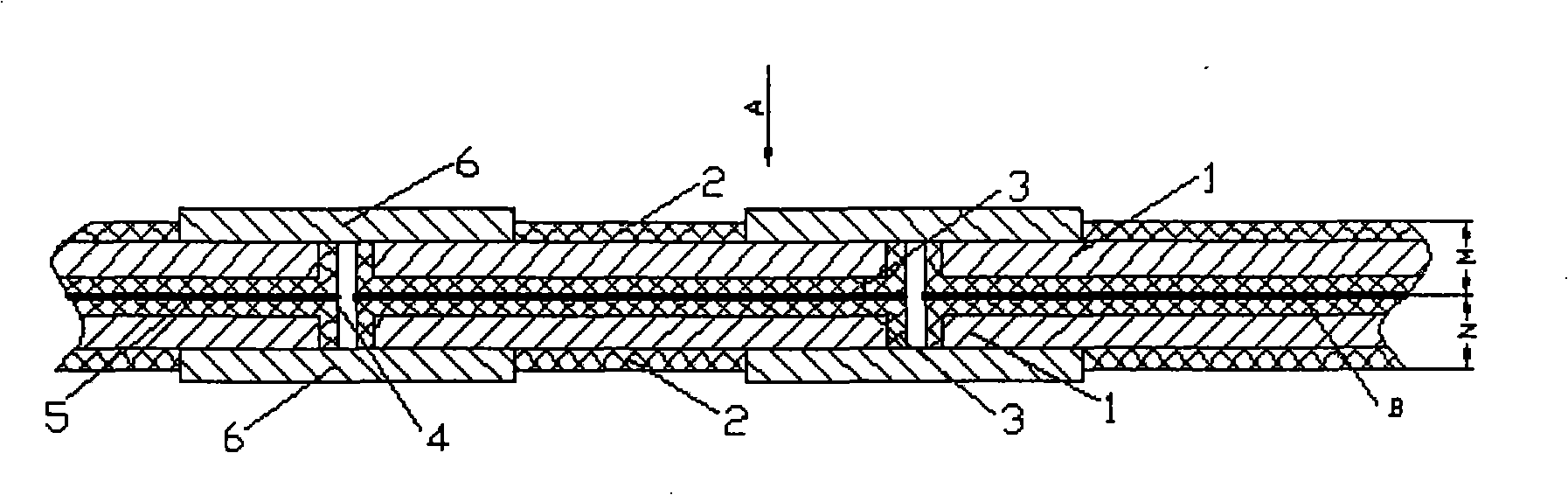

[0026] The preparation method of the compliant double-layer eddy current sensor for testing the curved surface gap proposed by the present invention, the structure of the prepared eddy current sensor is as follows figure 1 Shown, preparation method comprises the following steps:

[0027] (1) Open holes 4 on the polyimide film substrate 1 with a pore diameter of 250-350 μm;

[0028] (2) Lay copper foil on the front and back surfaces of the polyimide film substrate and the openings, the thickness of the polyimide film is 100 μm-200 μm, and the thickness of the copper foil is 15 μm-20 μm;

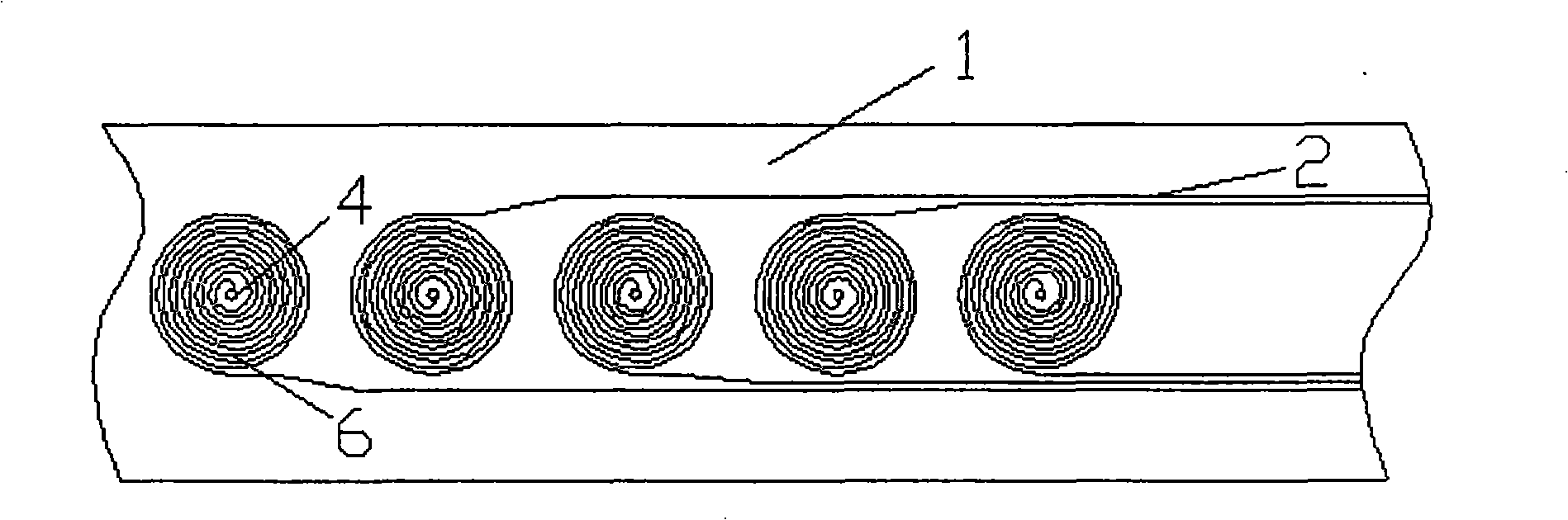

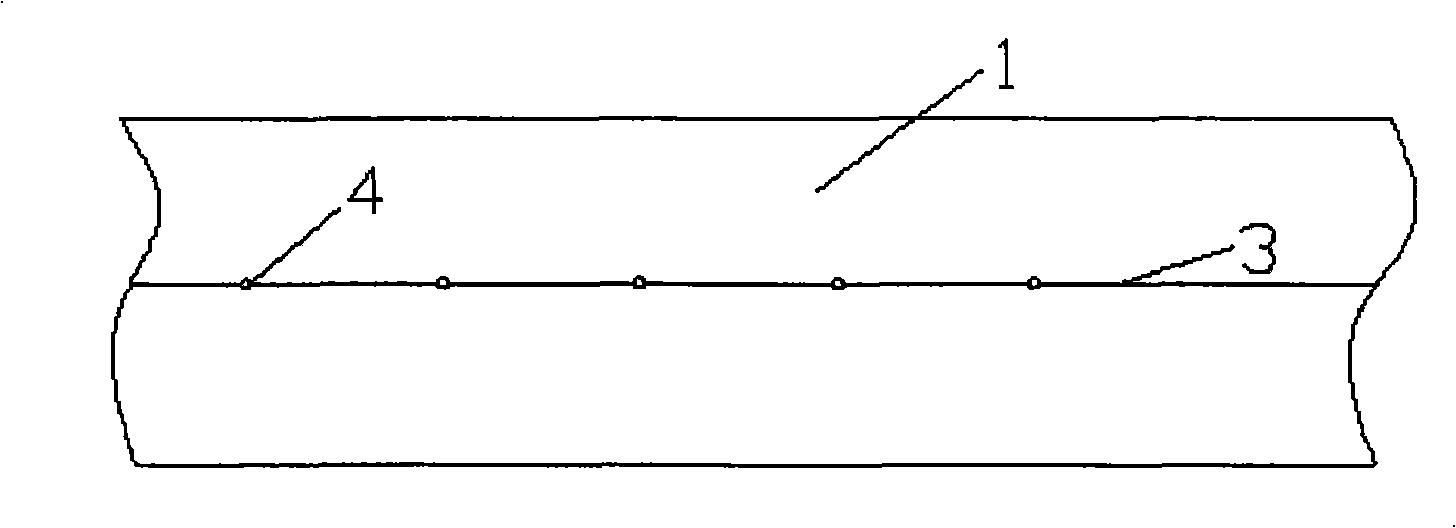

[0029] (3) Carry out photolithography on the above-mentioned front copper foil, form the eddy current coil 6 with the above-mentioned opening as the center, and form the outer lead 2 on one side of each eddy-current coil, as figure 2 shown. Photolithography is performed on the copper foil on the reverse side, and inner leads 3 are formed between the openings 4 to obtain an upper layer eddy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com