Method for locating and overlapping center of transformer core

A center positioning and transformer technology, which is applied in the manufacture of inductors/transformers/magnets, transformer/inductor cores, electrical components, etc., can solve the problems of core wrapping and inserting difficulties, etc. The effect of increasing stacking speed and reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

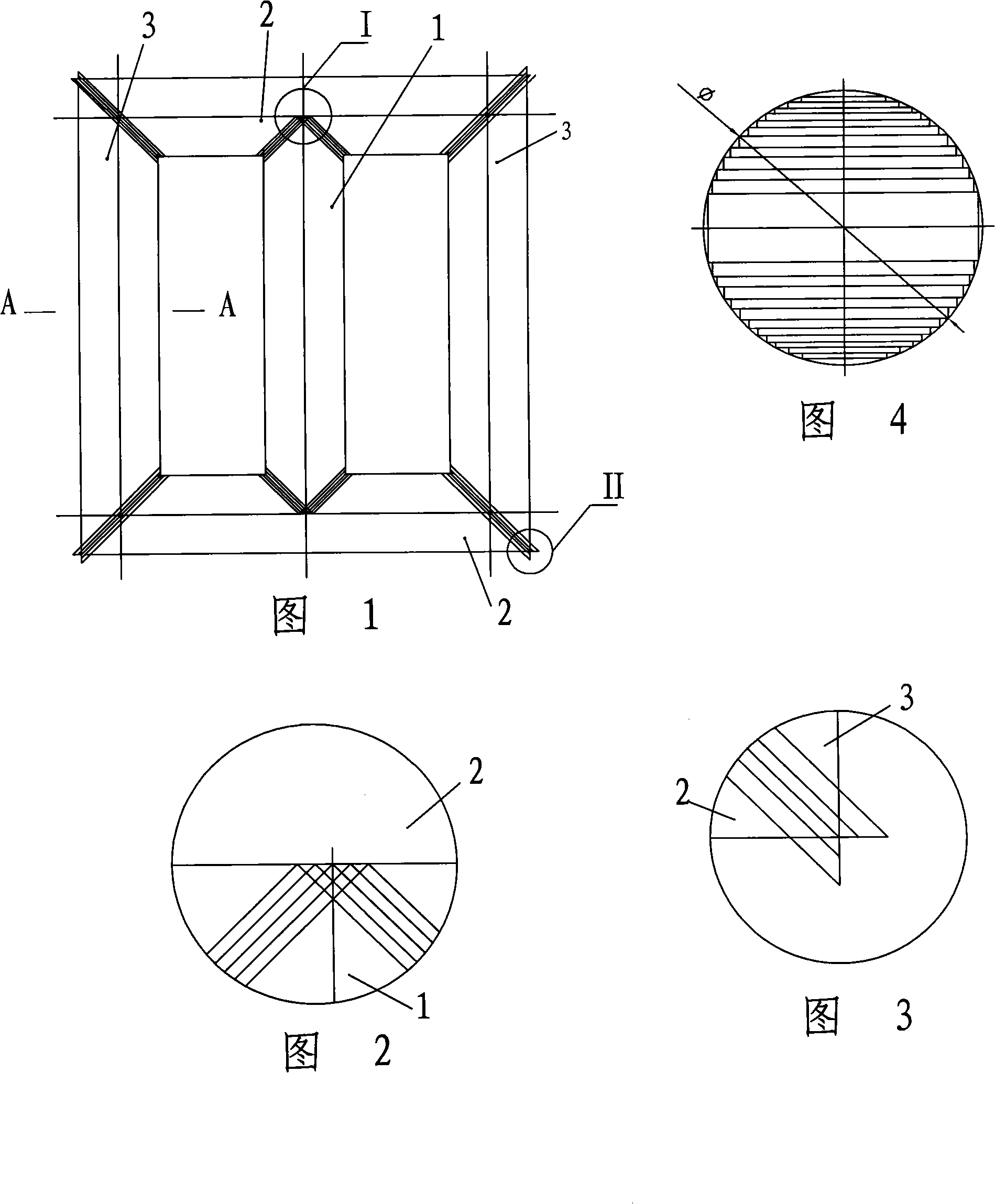

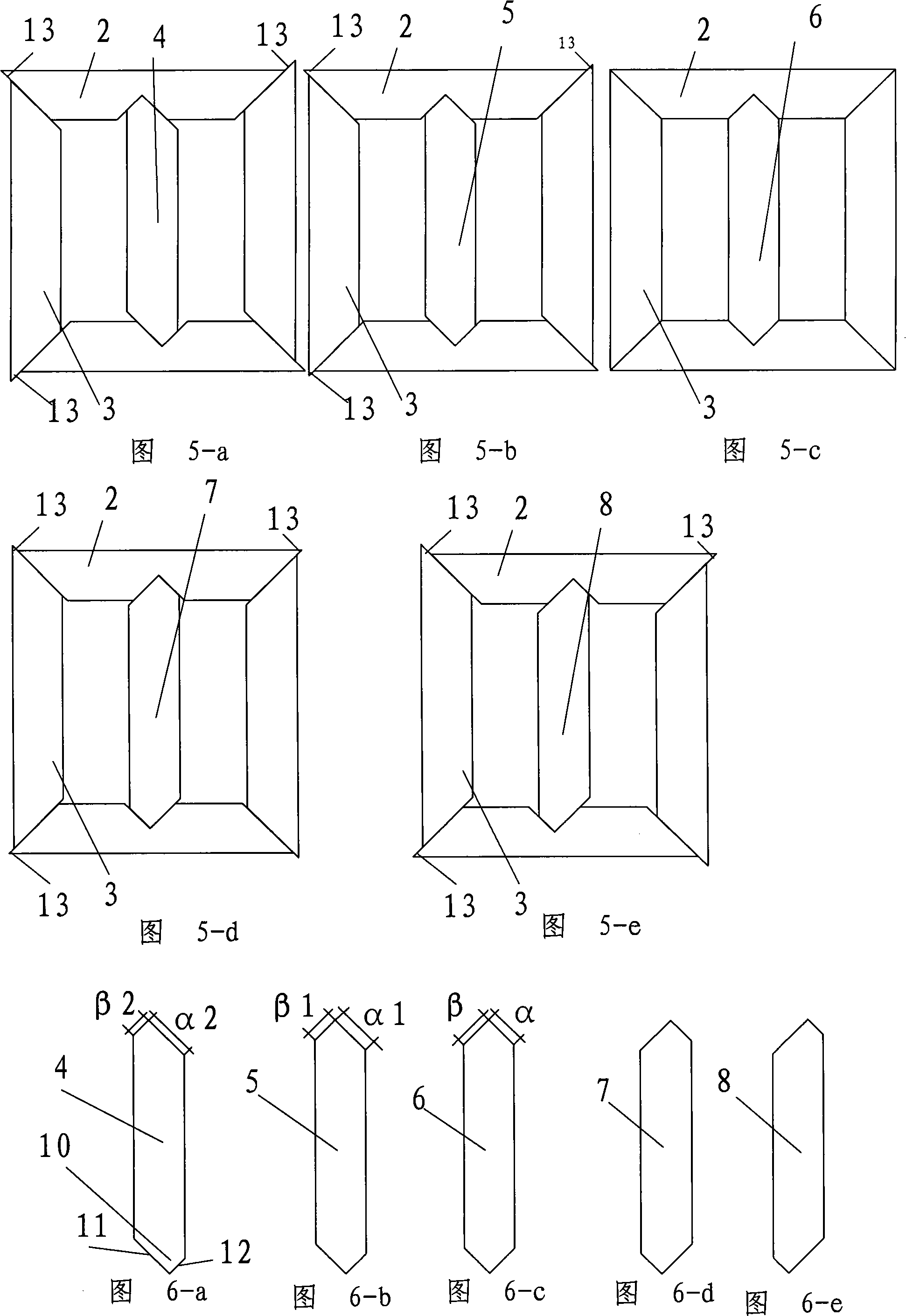

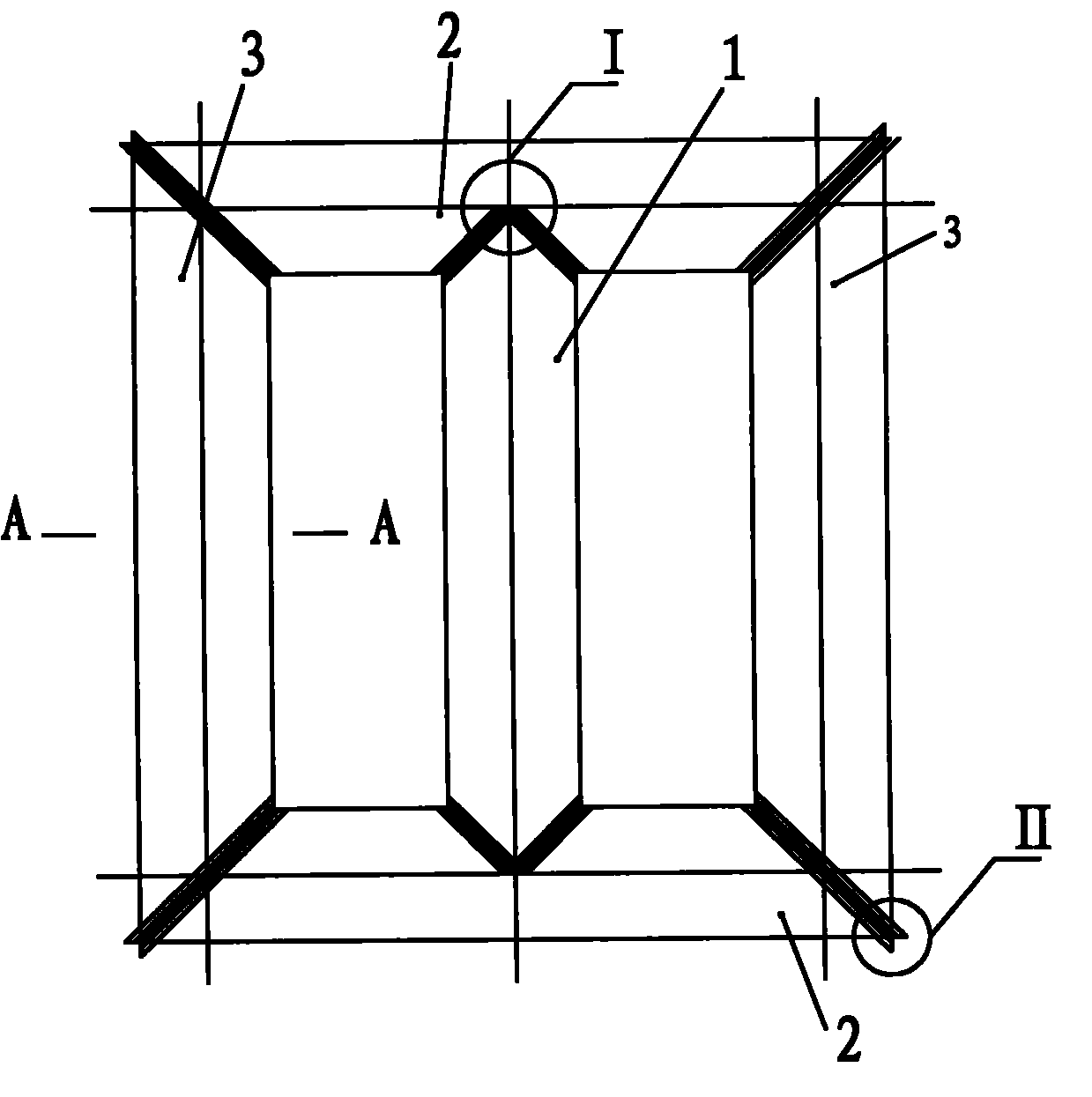

[0034] The center positioning and stacking method of the transformer iron core includes upper and lower yokes 2 located at the upper and lower ends of the iron core, side columns 3 located on the left and right sides of the iron core, and a central column 1 located in the middle of the iron core, wherein the side columns 3 and Central column 1 is parallel, it is characterized in that, described method comprises the following steps:

[0035] Step 1. Positioning: First position the center column 1, side column 3 and upper and lower yoke 2 on the positioning bracket;

[0036] Step 2, stacking the center column: stack several pieces of center column 1 on the positioning bracket in sequence;

[0037] Step 3, inserting pieces: After stacking all the pieces of the middle column 1, start to stack the upper and lower yokes 2 and the side columns 3. When stacking the upper and lower yokes 2 and the side columns 3, stack one piece of the upper and lower The sequence of stacking the yoke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com