Connection structure for conductor pipe in radio-frequency cable

A technology of radio frequency cables and conductor tubes, which is applied in the direction of screwing one conductor into another conductor, welding/welding connection, etc., which can solve the problems of too long aluminum tubes, affecting signal transmission quality, and inconvenient copper cladding process, etc., to ensure engineering use Requirements, the effect of ensuring the quality of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

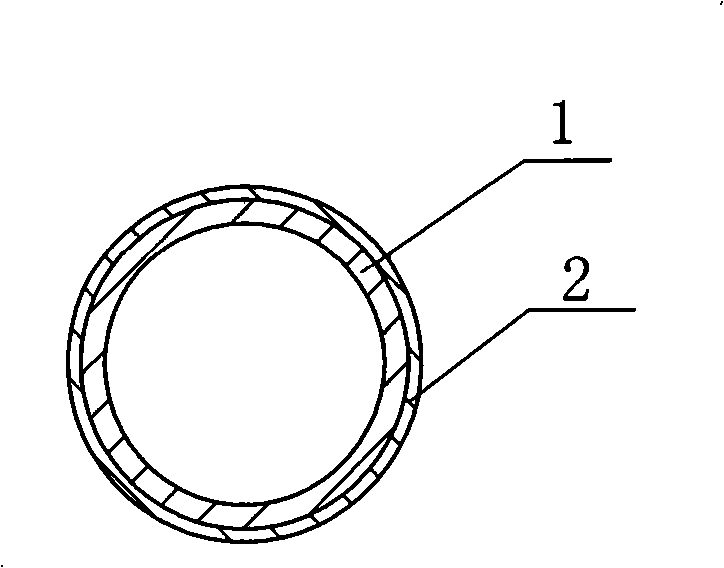

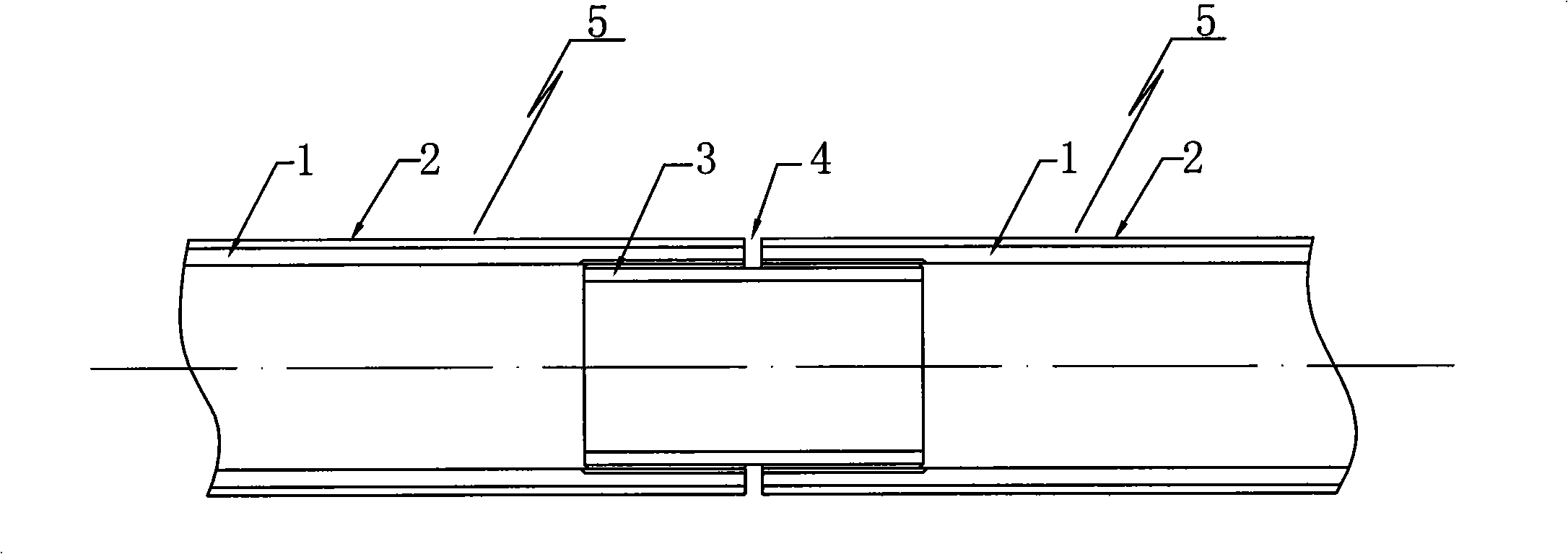

[0010] See figure 1 , figure 2 , the present invention includes a copper-clad aluminum pipe section 5, the two ends of the pipe section 5 are respectively processed with left-handed and right-handed internal threads, and the copper-clad aluminum pipe sections 5 are connected by double-headed left-handed and right-handed two-way threaded pipe joints 3 to form a long pipe. During the installation, as long as the rotating joint 3 is needed, the aluminum tubes on both sides can be connected as a whole, and then at the interface 4, the copper tubes 2 of the adjacent tube sections and the aluminum tubes 1 are respectively welded and connected, and then the copper tubes 2 are welded. Copper plated surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com