Electricity connector and conductive terminal as well as method for manufacturing the same

A technology of conductive terminals and connectors, which is applied in the direction of contact manufacturing, contact parts, etc., and can solve problems such as damage or fracture of conductive terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Since the present invention discloses an electrical connector and conductive terminal structure and a conductive terminal manufacturing method, the principle of electrical conduction used in it has been disclosed in detail in the prior art, so in the following description, for the electrical conduction Communication methods and transmission of electrical signals are not fully described. Moreover, the accompanying drawings in the following text are not completely drawn according to the actual relevant dimensions, and their function is only to express the schematic diagrams related to the features of the present invention.

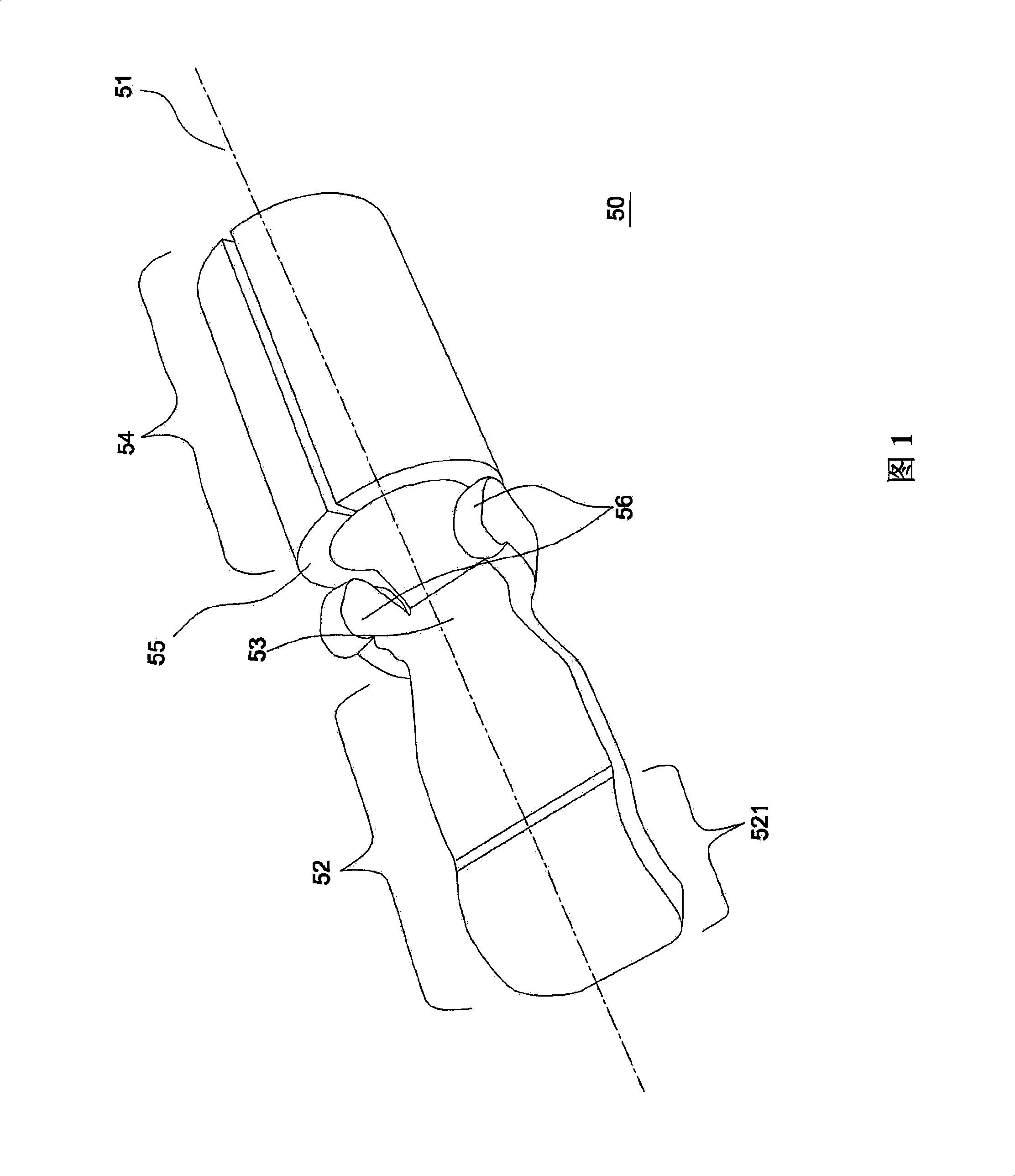

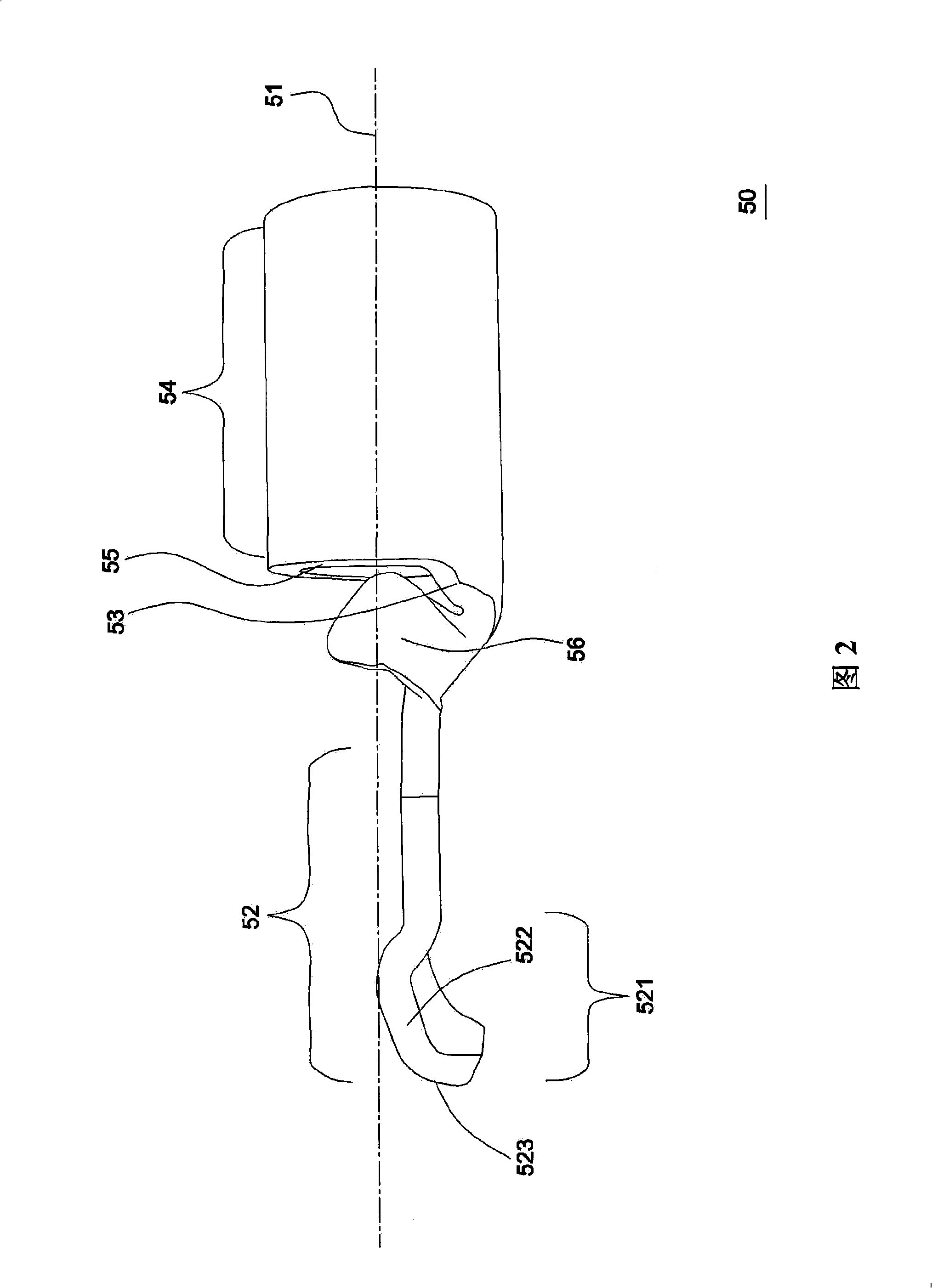

[0070] First of all, please refer to FIG. 1 and FIG. 2 , which are a perspective view and a side view of a conductive terminal of an electrical connector according to a first preferred embodiment of the present invention. The conductive terminal 50 includes a long axis 51 and a proximal end 52 , a waist 53 and a distal end 54 sequentially extending fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com