Plugging agent for oil-based drilling fluid as well as preparation method and application of plugging agent

A technology of oil-based drilling fluid and plugging agent, which is applied in the direction of drilling compositions, chemical instruments and methods, building components, etc., and can solve the problems of increased oil-based drilling fluid viscosity, poor plugging effect while drilling, and Use effect and other issues to achieve the effect of improving high temperature stability, increasing softening point, and improving use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

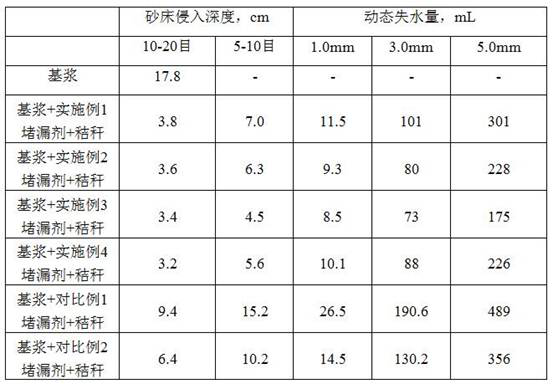

Examples

Embodiment 1

[0039]Put 50g of orthophosphoric acid in the flask, add 25g of phosphorus pentoxide uniformly and slowly in 3 times, and react the above solution under the condition of heating while stirring. The stirring speed was 250 rpm, the temperature was 100° C., and the reaction time was 30 minutes to obtain a modifier.

[0040] Heat 200g of straight-run asphalt to a molten state, add 17.5g of the modifier prepared above, stir and mix at 140°C for 35min to obtain modified matrix asphalt. Heat 15.2g of the extracted oil to 130°C, add 8.6g of SBS to fully swell and melt it, then add it to the above-mentioned modified base asphalt, and use a high-speed shear emulsifier for shearing, the shearing temperature is 185°C, and the shearing time is 35min. Then place it in an oven at 170° C. for 2 hours to obtain modified asphalt.

[0041] Add 36.5g of silicon micropowder (250 mesh) to the obtained modified asphalt and cut it for 30 minutes, cool it to room temperature and put it in a -30°C free...

Embodiment 2

[0044] Put 60g of orthophosphoric acid in the flask, add 20g of phosphorus pentoxide uniformly and slowly in 3 times, and react the above solution under the condition of heating while stirring. The stirring speed was 350 rpm, the temperature was 115° C., and the reaction time was 40 minutes to obtain a modifier.

[0045] Heat 200g of straight-run asphalt to a molten state, add 12.6g of the modifier prepared above, stir and mix at 145°C for 45min to obtain modified matrix asphalt. Heat 11.5g of naphthenic oil to 140°C, add 7.5g of SBS to fully swell and melt, add it to the above-mentioned modified base asphalt, and use a high-speed shear emulsifier for shearing, with a shearing temperature of 180°C and a shearing time of 30 minutes. Then place it in an oven at 175°C for 3.5 hours to develop modified asphalt.

[0046] Add 28.4g of silicon micropowder (325 mesh) to the obtained modified asphalt and cut it for 30 minutes, cool it to room temperature and put it in a -40°C freezer ...

Embodiment 3

[0049] Put 45g of orthophosphoric acid in the flask, add 16.8g of phosphorus pentoxide uniformly and slowly in 3 times, and react the above solution under the condition of heating while stirring. The stirring speed was 300 rpm, the temperature was 120° C., and the reaction time was 45 minutes to obtain a modifier.

[0050] Heat 200g of straight-run asphalt to a molten state, add 8.5g of the modifier prepared above, stir and mix at 150°C for 40min to obtain modified matrix asphalt. Heat 17.2g of the extracted oil to 145°C, add 9.8g of SBS to fully swell and melt it, then add it to the above-mentioned modified base asphalt, and use a high-speed shear emulsifier for shearing, the shearing temperature is 190°C, and the shearing time is 45min. Then place it in an oven at 165° C. for 2.5 hours to obtain modified asphalt.

[0051] Add 43.6g of silicon micropowder (225 mesh) to the obtained modified asphalt and cut it for 40 minutes, cool it to room temperature and put it in a -35°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com