Disposable diaper

A disposable, diaper technology, applied in non-woven fabrics, clothing, textiles and papermaking, etc., can solve the problems of high energy, high production costs, and inability to perform bonding force, etc., to achieve the effect of reducing costs and improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

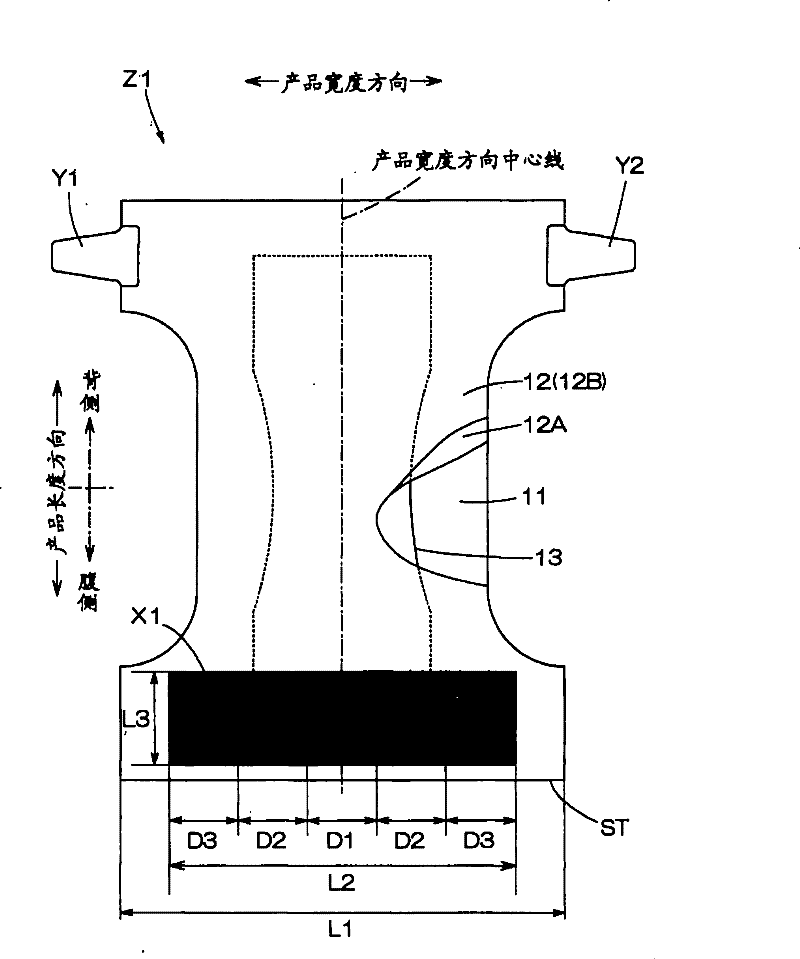

[0101] figure 1 It is fastening type disposable diaper Z1 which concerns on 1st Embodiment of this invention. This disposable diaper Z has: a liquid-permeable top sheet 11 located on the user's skin side; a liquid-impermeable back sheet 12 located on the outside of the product and substantially impervious to liquid; and an absorber 13, It is arranged between the surface sheet 11 and the back sheet 12, and is, for example, rectangular or preferably hourglass-shaped and has a certain degree of rigidity. Fastening belts for fastening are provided on the left and right side edges of the back side. Y1, Y2.

[0102] The fastening tapes Y1 and Y2 are formed of the hook surface material of the surface buckle except for the parts bonded to the left and right side edges and the front end part constituting the grip part, and the joint part X1 joining the hook surface material is arranged. On the ventral side of the outer surface of the back sheet 12.

[0103] The back sheet 12 is wide...

no. 2 approach

[0137] In the first embodiment, the loop material sheet is pasted on the back sheet as the joint portion X1 of the fastening tapes Y1, Y2, but in the second embodiment, the loop material sheet is not pasted on the back sheet. On the back sheet, instead, a part of the outer surface of the back sheet 12 itself is appropriately embossed to form a matte material portion, and this is used as the joining portion X1, which is a so-called non-target tape form. Figure 4 The disposable diaper Z2 of this 2nd Embodiment is shown. Hereinafter, the second embodiment will be described focusing on points different from the first embodiment.

[0138] The backsheet 12 of the first aspect does not necessarily have to be equipped with the nonwoven fabric sheet 12B for exterior, but in the second aspect, the nonwoven fabric sheet 12B or the woven fabric is usually arranged on the outer surface side in order to improve the skin feel and form a junction. piece.

[0139] The bonding method of the ...

no. 3 approach

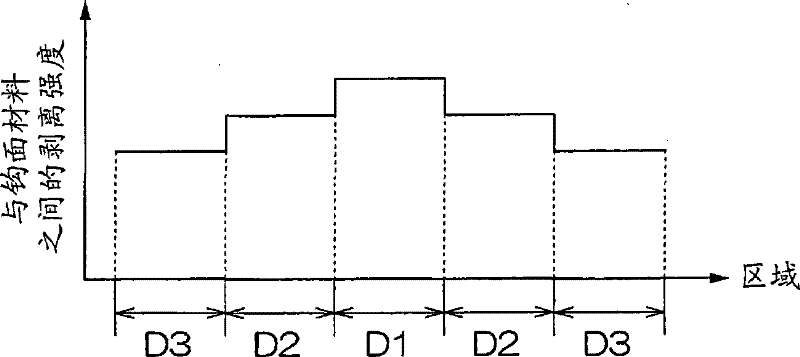

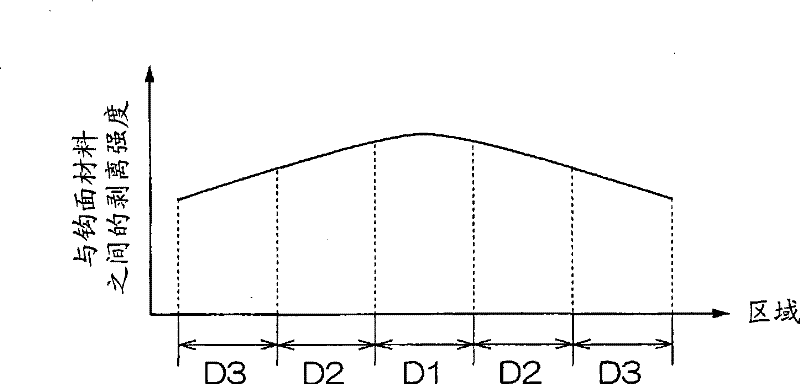

[0149] Figure 5 The disposable diaper Z3 of 3rd Embodiment is shown. The junction part X1 of the disposable diaper Z3 of 3rd aspect is formed by the assembly of some junction part unit x, x.... These joining part units x, x... are formed by dividing the nap material sheet of the surface button into small pieces. Furthermore, the junction is formed by five regions having different sizes of these junction units x, x..., the largest junction unit is used in the central region D1, and the peel strength is the highest. The size of the junction unit used is Since the region D2 adjacent to the region D1 becomes smaller in order, and the region D3 further adjacent to the region D2 becomes smaller, the peel strength is configured to decrease toward both side edges. In addition, the size of the junction part units x, x... may be the same in each region, and the peeling strength with the hook surface material may differ in each region by making it differ in arrangement|positioning den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com