Method and apparatus for realizing rapid axial feed on precise machine tool

An axial feed, precision machine tool technology, applied in feeding devices, auxiliary devices, accessories of tool holders, etc., can solve the problems of increasing labor intensity and processing time, and achieve reduced labor intensity, obvious effect, and production efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

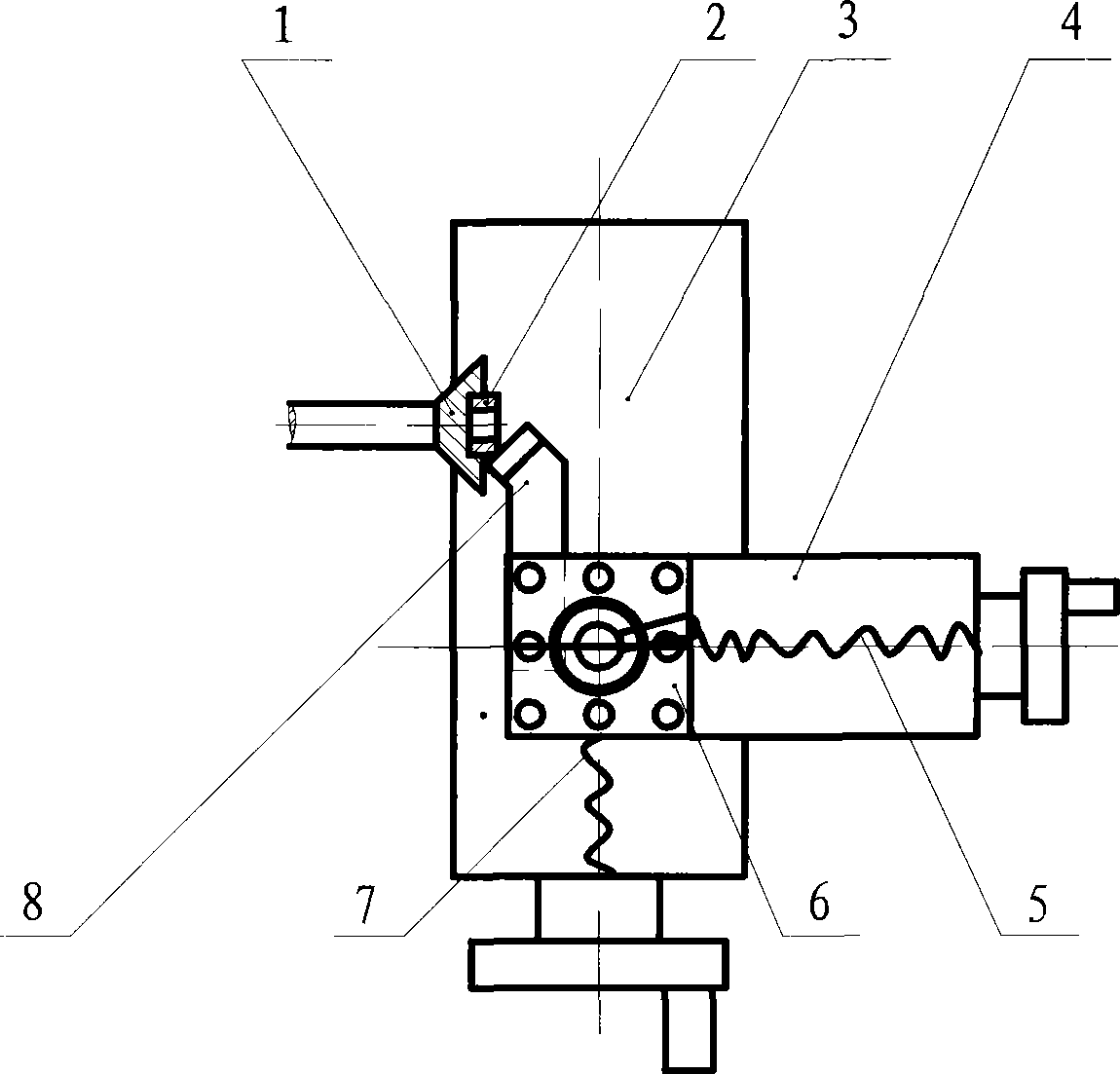

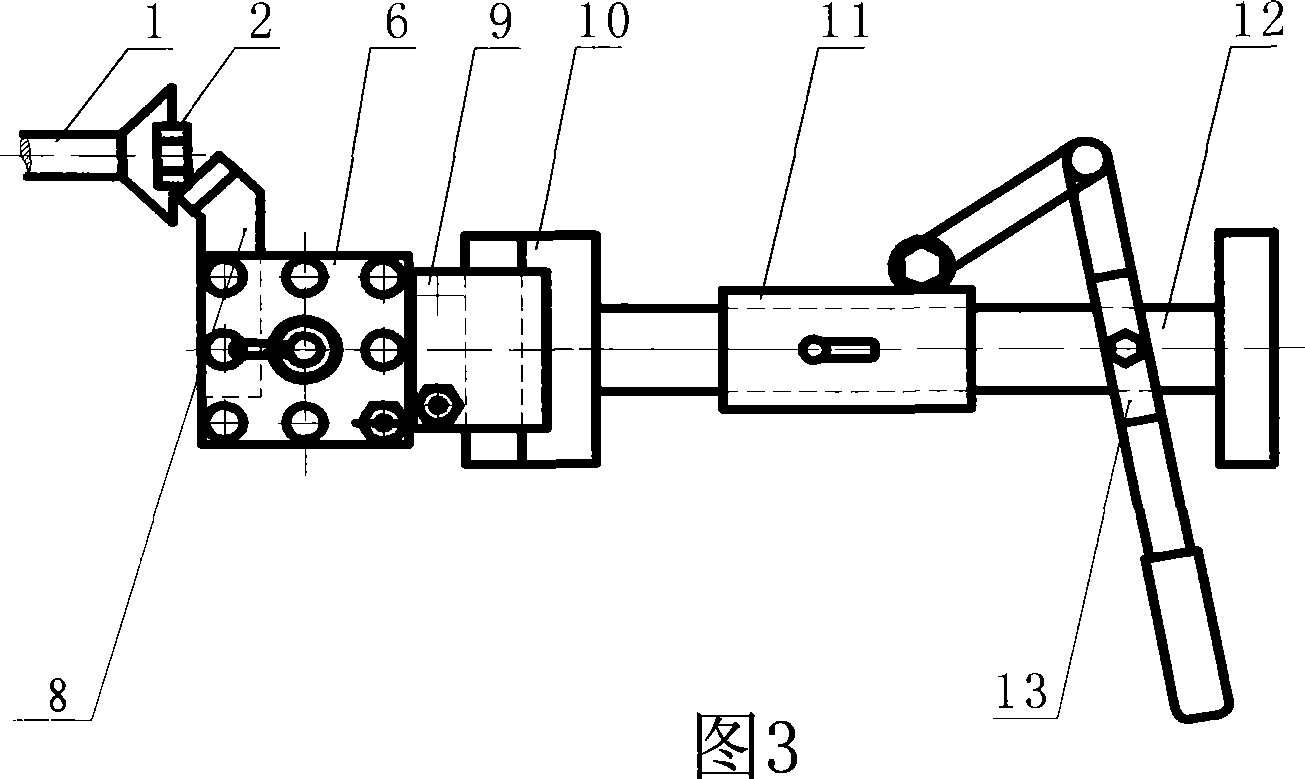

[0034] The method for realizing rapid axial feed on a precision machine tool of the present invention comprises the following contents:

[0035] 1) Remove the small pallet screw, add a set of rapidly retractable axial feed device, and change the rotary feed of the small pallet screw to the linear feed of the axial feed device;

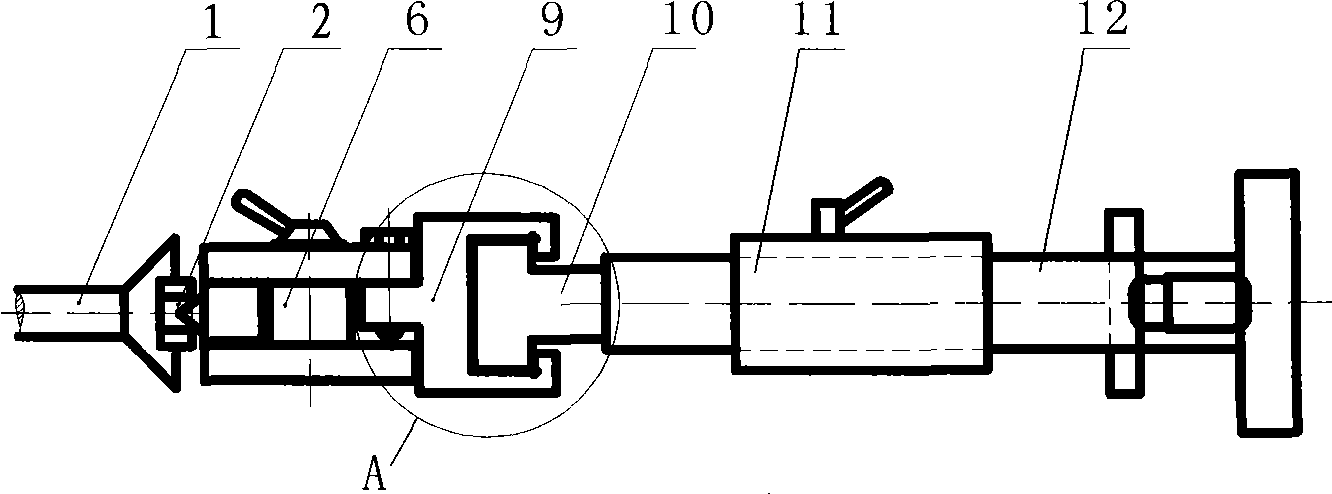

[0036] 2) The tailstock of the tailstock mandrel in the axial feed device is fixed on the sliding guide rail of the machine tool, and a shaft hole is provided on the tailstock, and the tailstock mandrel can perform axial reciprocating linear motion along the shaft hole, and the manipulation of reciprocating linear motion It is realized by a wrench, and the wrench is composed of two rotatable connecting rods, one is fixed at the tail of the tailstock mandrel, and the other is fixed at the side of the slider;

[0037] 3) The axial positioning of the turning tool is realized by the stop iron on the left side of the tool holder;

[0038] 4) Connect the C-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com