Concrete containing low-quality coarse aggregate and preparation thereof

A kind of technology of concrete and coarse aggregate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

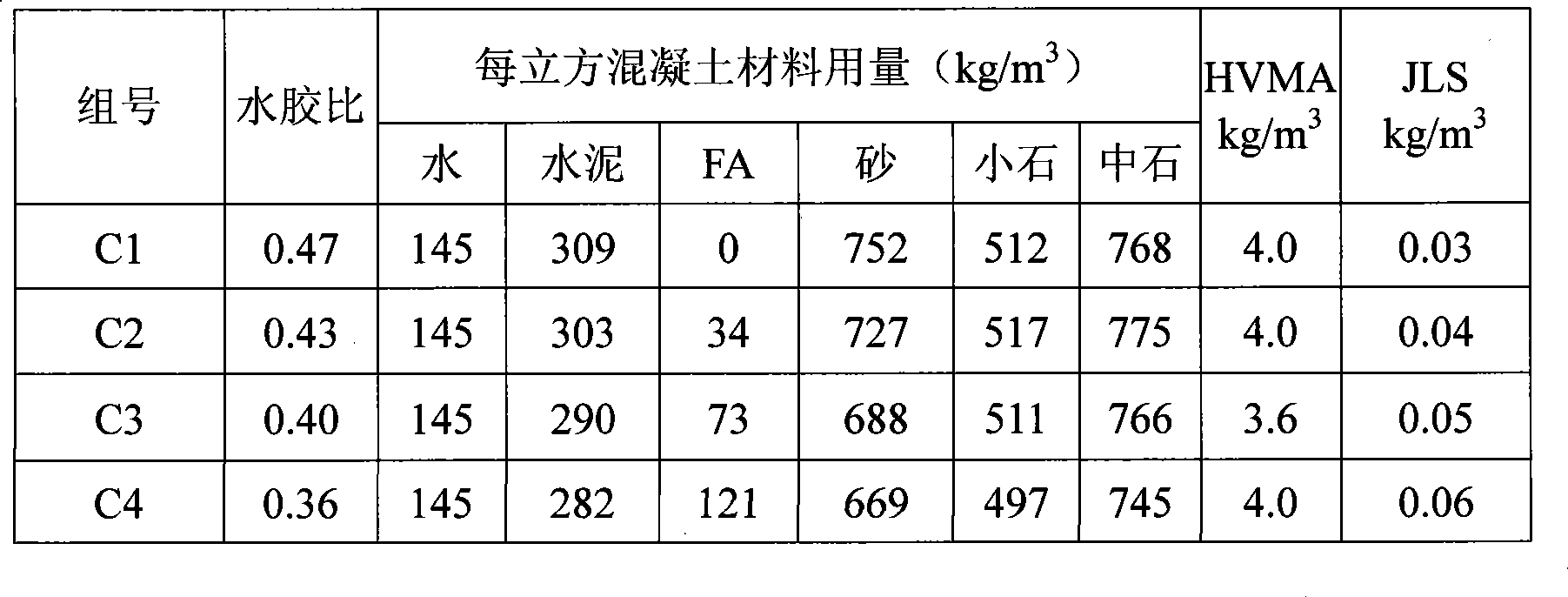

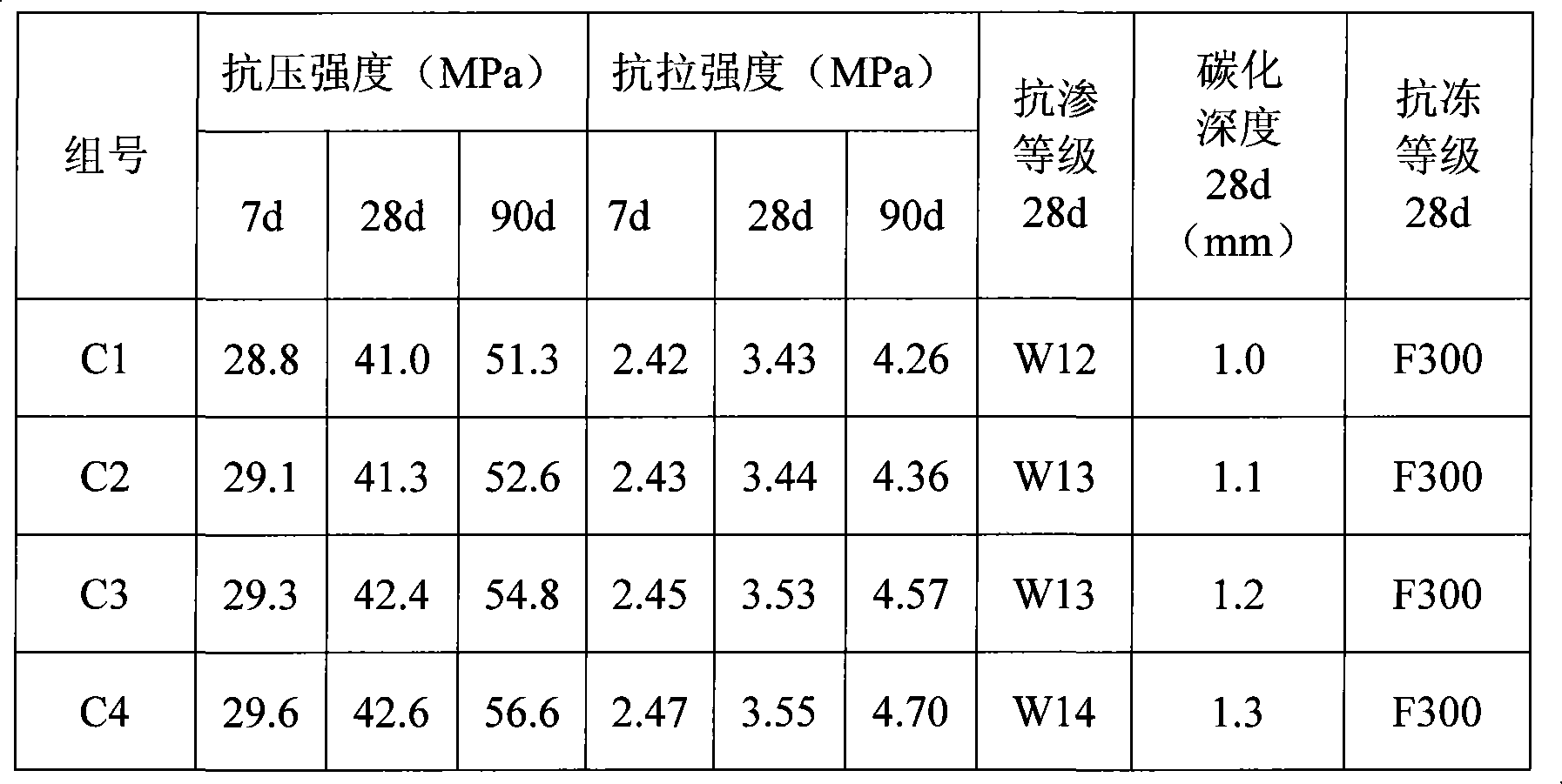

Embodiment 1

[0018] Concrete prepared with low-quality coarse aggregate from a certain production area requires design compressive strength grade C30, impermeability W6, 28d carbonation depth ≤ 5mm, and frost resistance F100. Use the existing preparation technology to add 4-6kg / m2 to the low-quality coarse aggregate concrete 3 Naphthalene water reducer and 0.04~0.08kg / m 3 Rosin thermal polymer air-entraining agent, the concrete compressive strength can meet the design requirements, but the durability can not meet (impermeability lower than W6, 28d carbonation depth> 5mm, frost resistance can only reach F50). The invention adds ultra-fine fly ash, polycarboxylate water reducing agent, sodium lauryl sulfate air-entraining agent and high-aged soil material into low-quality coarse aggregate concrete to prepare high-durability concrete. The preparation method is as follows:

[0019] (1) 282~309kg / m 3 Cement, 0~121kg / m 3 Superfine fly ash, 60~80kg / m 3 Put the water into the self-falling mix...

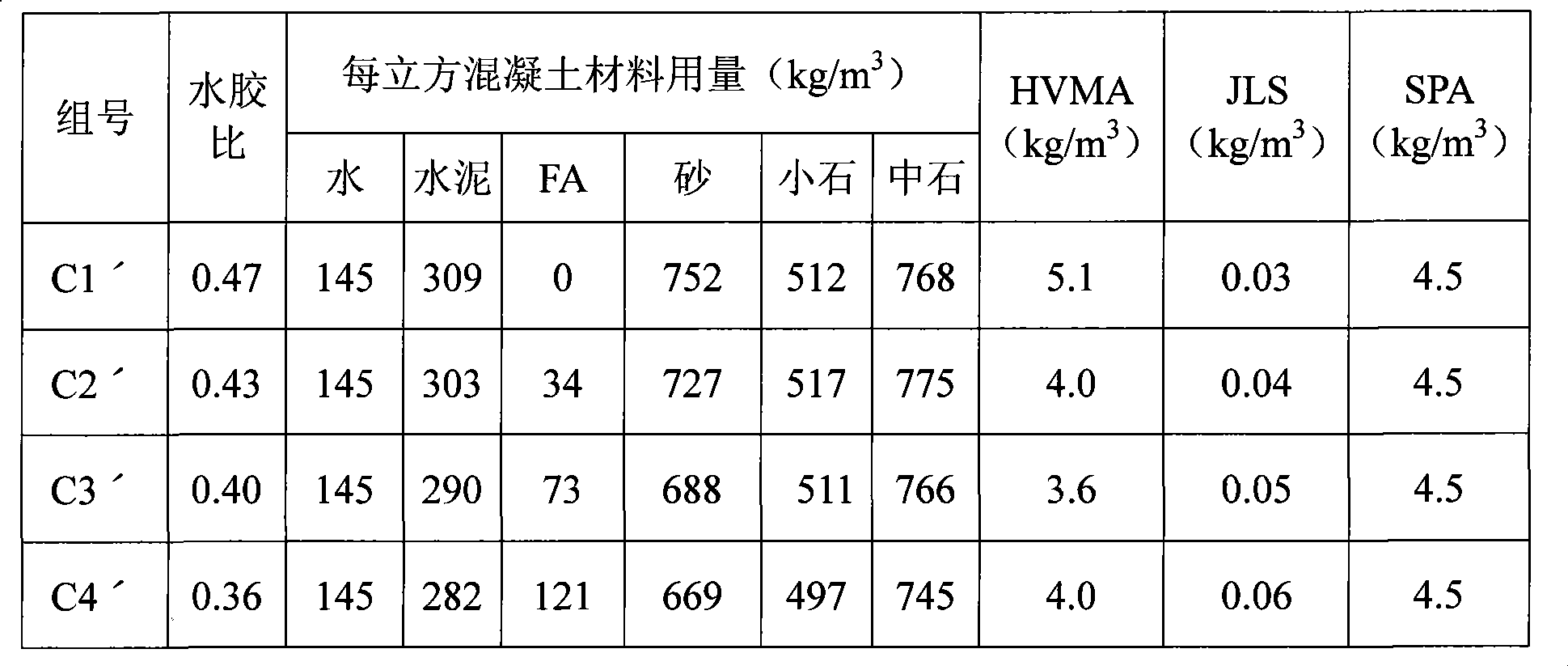

Embodiment 2

[0029] Concrete is prepared with low-quality coarse aggregate from a certain production area, and the design compressive strength grade C30, impermeability W8, 28d carbonation depth 5mm, and frost resistance F150 are required. Use the existing preparation technology to add 4-6kg / m2 to the low-quality coarse aggregate concrete 3 Naphthalene water reducer and 0.04~0.08kg / m 3 Rosin thermal polymer air-entraining agent, the concrete compressive strength can meet the design requirements, but the durability can not meet (impermeability lower than W6, 28d carbonation depth> 5mm, frost resistance can only reach F100). The invention adds ultra-fine fly ash, polycarboxylate water reducer, sodium lauryl sulfate air-entraining agent, older soil material and superabsorbent resin particles into low-quality coarse aggregate concrete to prepare high-durability concrete. The preparation method is as follows:

[0030] (1) 282~309kg / m 3 Cement, 0~121kg / m 3 Superfine fly ash, 60~80kg / m 3 Put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com