Drum-type washing machine

A drum-type washing machine, drum-type technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of unfixed working positions, complicated settings, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. At the same time, it should be pointed out that such embodiments do not limit the scope of the present invention.

[0030] (Example)

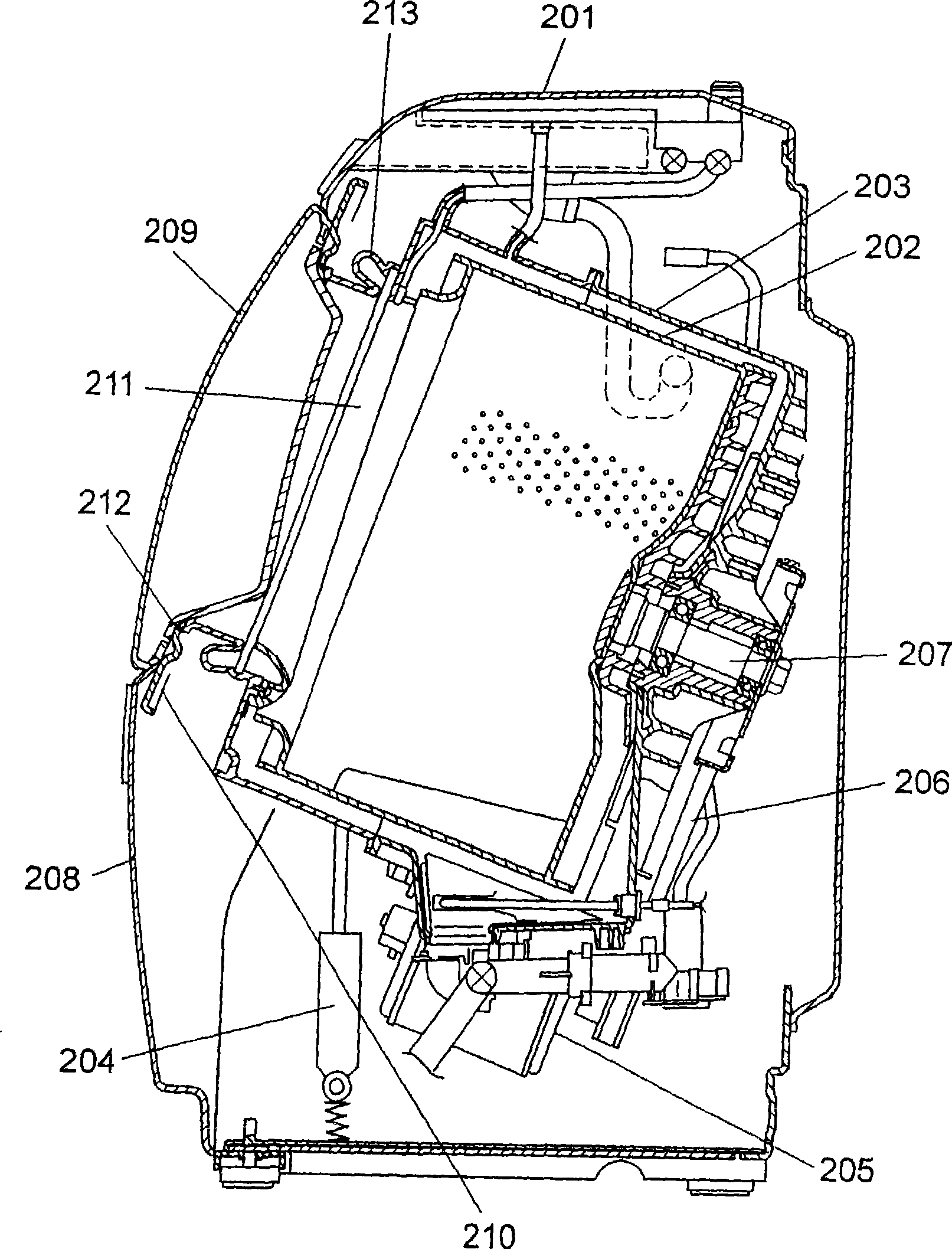

[0031] Such as figure 1 As shown in , a washing machine casing 201 is provided with a tub 203 inside, and a drum-type washing tub 202 that can rotate freely is provided inside the tub 203 . An anti-vibration device 204 is installed on the outer bottom of the water tub 203, and the entire water tub 203 is supported on the bottom of the washing machine shell 201 in an anti-vibration manner. A motor 205 is also fixed on the outer bottom of the water tub 203, and the rotation of the motor 205 is transmitted to the rotating shaft 207 through the belt 206, so that the drum-type washing tub 202 is rotated to perform laundry or dehydration operations.

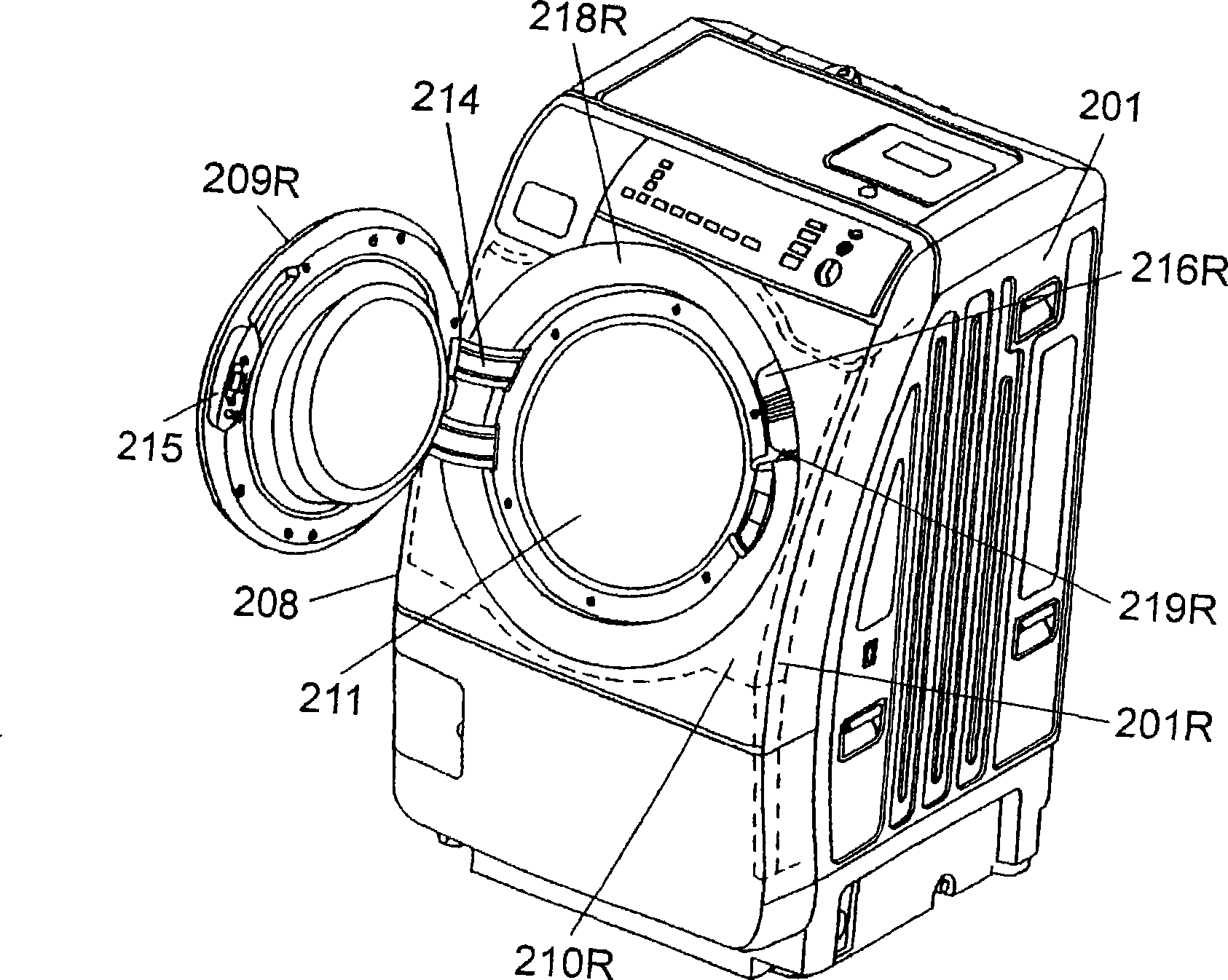

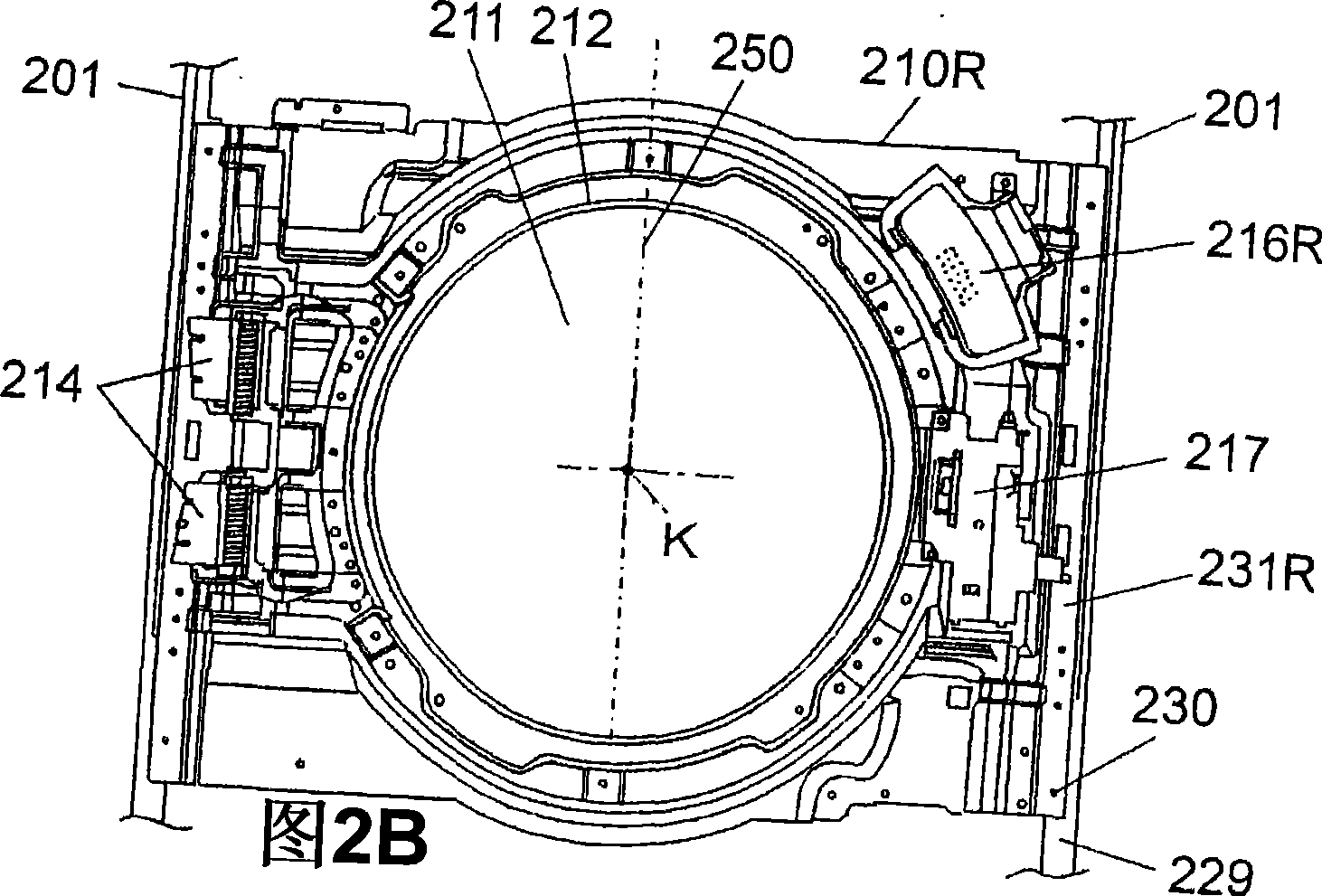

[0032]In front of the washing machine casing 201 (i.e. figure 1 The lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com