Water belt

A hose, braided technology, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor stiffness and elasticity, inconvenience, and easy aging of plastic water pipes.

Inactive Publication Date: 2009-04-22

5ELEM HI TECH CORP

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the softness of polyester or polypropylene filaments, poor rigidity and elasticity, when the hose is coiled or severely bent, the inner wall of the hose is tightly attached to each other, and water cannot be transported. Only when the hose is fully extended can it be used. Very inconvenient, especially not suitable for emergencies

Recently, a kind of plastic water pipe has appeared, and steel wire is arranged in the pipe. Although the problem of water conveyance when the hose is wound has been solved, the plastic water pipe is easy to age and has a short service life.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

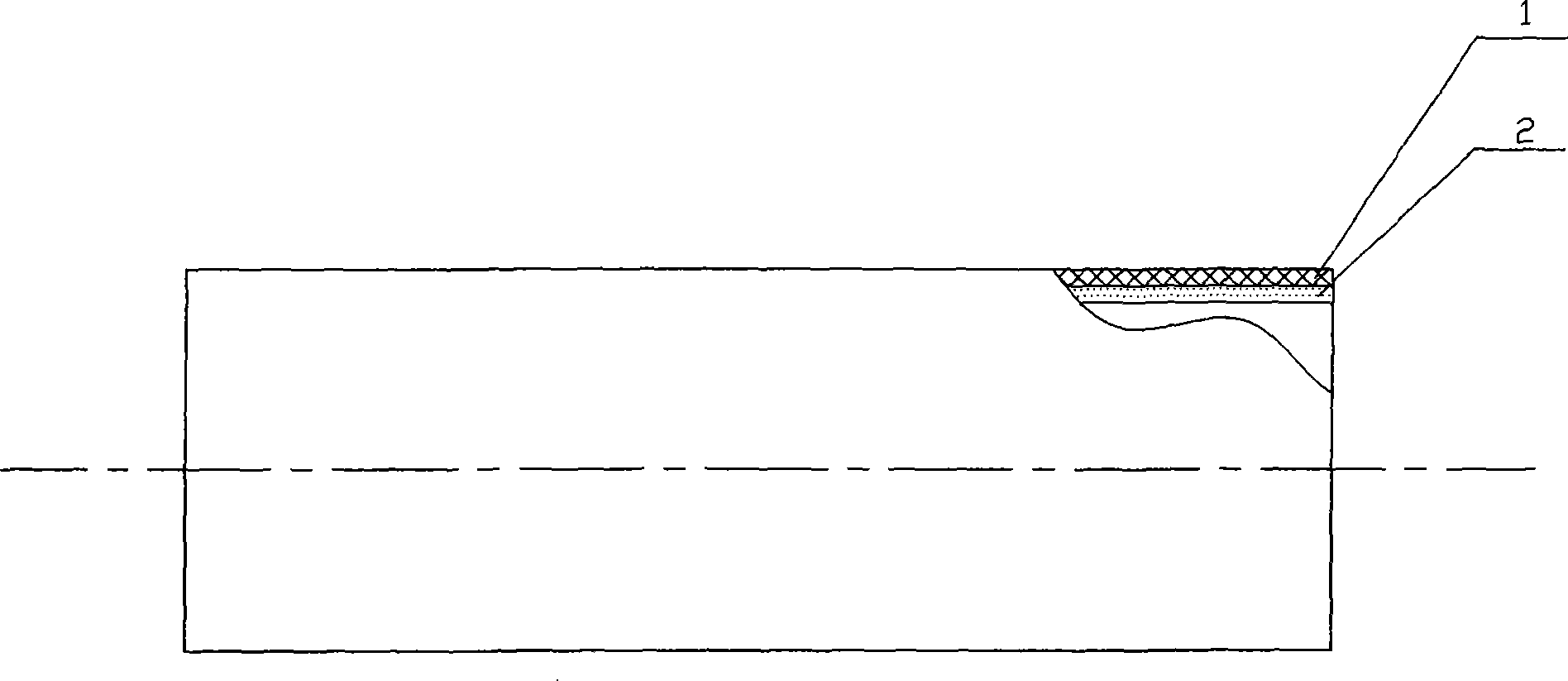

[0008] Referring to the accompanying drawings, the hose is composed of a braided layer 1 and an inner lining layer 2, the weft in the braided layer is a spiral polyester monofilament with a diameter of 1mm, and the warp is a polyester filament. The inner liner is a rubber-plastic coating.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a water belt which consists of a knitting layer and a lining layer; the woof in the knitting layer is polyester monofilament which is wound as spiral shape and the warp in the knitting layer is polyester filament or polypropylene textured filament; the diameter of the polyester monofilament is 0.5-1.5mm. The water belt is used for water conveying pipes in fire control, agriculture and industry production; as the polyester monofilament has high strength, rigidity and elasticity and good comprehensive performance, the water belt can smoothly convey the water even when being wound or severely bent, has convenient usage, is especially suitable for emergent sites, has good wearability, is not easy to age, and has long service life. Furthermore, the water belt can be also used for connecting pipelines.

Description

technical field [0001] The invention relates to a water belt used for fire protection or water transport in industrial and agricultural production. Background technique [0002] The hose used for fire protection or industrial and agricultural production is usually composed of a braided layer and an inner lining (lined hose), and the braided layer is generally woven with high-strength polyester or polypropylene yarns as warp and weft. Due to the softness of polyester or polypropylene filaments, poor rigidity and elasticity, when the hose is coiled or severely bent, the inner wall of the hose is tightly attached to each other, and water cannot be transported. Only when the hose is fully extended can it be used. Very inconvenient, especially more inapplicable to emergency situations. A kind of plastic water delivery pipe has occurred recently, and steel wire is set in the pipe, though solved the water delivery problem when the hose is wound, but the plastic water pipe is easy ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16L11/02

Inventor 沙月华肖爱桦李志江

Owner 5ELEM HI TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com